What is Global Vacuum Formed Ceramic Fiber Market?

The Global Vacuum Formed Ceramic Fiber Market is a specialized segment within the broader ceramic fiber industry, focusing on products made from vacuum-formed ceramic fibers. These fibers are known for their excellent thermal insulation properties, lightweight nature, and resistance to high temperatures, making them ideal for various industrial applications. The market is driven by the increasing demand for energy-efficient solutions and the need for materials that can withstand extreme conditions. Vacuum-formed ceramic fibers are used in industries such as steel, aluminum, petrochemicals, and power generation, where high-temperature insulation is crucial. The market is characterized by continuous innovation and development of new products to meet the evolving needs of different industries. Additionally, environmental regulations and the push for sustainable materials are influencing market dynamics, encouraging manufacturers to develop eco-friendly products. The market's growth is also supported by advancements in manufacturing technologies, which enhance the performance and durability of ceramic fiber products. Overall, the Global Vacuum Formed Ceramic Fiber Market is poised for significant growth, driven by technological advancements and the increasing demand for high-performance insulation materials.

Pipe, Block, Board, Others in the Global Vacuum Formed Ceramic Fiber Market:

In the Global Vacuum Formed Ceramic Fiber Market, products are categorized into various forms, including pipes, blocks, boards, and others, each serving distinct purposes and applications. Pipes made from vacuum-formed ceramic fibers are primarily used for insulating piping systems in high-temperature environments. These pipes are lightweight, easy to install, and provide excellent thermal insulation, making them ideal for industries such as petrochemicals, power generation, and metallurgy. The ability of ceramic fiber pipes to withstand extreme temperatures and resist thermal shock makes them a preferred choice for applications where traditional insulation materials may fail. Blocks, on the other hand, are used in applications requiring robust and durable insulation solutions. Vacuum-formed ceramic fiber blocks are designed to provide superior thermal insulation and are often used in furnaces, kilns, and other high-temperature industrial equipment. Their high compressive strength and resistance to thermal shock make them suitable for demanding environments where insulation integrity is critical. Boards made from vacuum-formed ceramic fibers are versatile and can be used in a wide range of applications. They are commonly used as insulation in industrial ovens, kilns, and other high-temperature processing equipment. The boards offer excellent thermal stability, low thermal conductivity, and resistance to chemical attack, making them ideal for harsh industrial environments. Additionally, vacuum-formed ceramic fiber boards are easy to cut and shape, allowing for customized insulation solutions tailored to specific applications. Other forms of vacuum-formed ceramic fiber products include custom shapes and components designed for specific industrial applications. These products are often used in specialized equipment where standard insulation solutions may not be suitable. The ability to customize vacuum-formed ceramic fiber products allows manufacturers to meet the unique needs of different industries, enhancing the overall performance and efficiency of their operations. Overall, the diverse range of products available in the Global Vacuum Formed Ceramic Fiber Market ensures that industries have access to high-performance insulation solutions tailored to their specific requirements.

Industrial, Laboratory, Other in the Global Vacuum Formed Ceramic Fiber Market:

The Global Vacuum Formed Ceramic Fiber Market finds extensive usage across various sectors, including industrial, laboratory, and other specialized applications. In the industrial sector, vacuum-formed ceramic fibers are primarily used for thermal insulation in high-temperature environments. Industries such as steel, aluminum, petrochemicals, and power generation rely on these fibers to enhance energy efficiency and protect equipment from thermal damage. The fibers' ability to withstand extreme temperatures and resist thermal shock makes them ideal for use in furnaces, kilns, and other high-temperature processing equipment. Additionally, vacuum-formed ceramic fibers are used in the construction of industrial ovens and boilers, where they provide excellent thermal insulation and contribute to energy savings. In laboratory settings, vacuum-formed ceramic fibers are used for insulation in high-temperature furnaces and kilns. These fibers provide a stable and controlled environment for conducting experiments and testing materials at elevated temperatures. The fibers' low thermal conductivity and resistance to chemical attack make them suitable for use in laboratory equipment where precise temperature control is essential. Furthermore, vacuum-formed ceramic fibers are used in the production of laboratory crucibles and other high-temperature components, ensuring the integrity and reliability of experimental results. Beyond industrial and laboratory applications, vacuum-formed ceramic fibers are used in various other specialized areas. For instance, they are employed in the aerospace industry for thermal insulation in aircraft engines and components. The fibers' lightweight nature and excellent thermal properties make them ideal for use in aerospace applications where weight and performance are critical considerations. Additionally, vacuum-formed ceramic fibers are used in the automotive industry for exhaust system insulation and heat shields, contributing to improved vehicle performance and fuel efficiency. The versatility and high-performance characteristics of vacuum-formed ceramic fibers make them suitable for a wide range of applications, ensuring their continued demand across different sectors.

Global Vacuum Formed Ceramic Fiber Market Outlook:

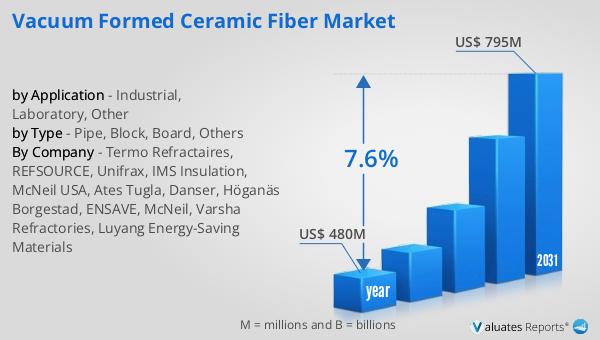

The global market for vacuum-formed ceramic fiber was valued at approximately $480 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $795 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.6% over the forecast period. The market's expansion is driven by the increasing demand for high-performance insulation materials across various industries, including steel, aluminum, petrochemicals, and power generation. The need for energy-efficient solutions and materials that can withstand extreme temperatures is fueling the adoption of vacuum-formed ceramic fibers. Additionally, advancements in manufacturing technologies and the development of eco-friendly products are contributing to market growth. As industries continue to prioritize energy efficiency and sustainability, the demand for vacuum-formed ceramic fibers is expected to rise, supporting the market's positive outlook. The market's growth is also influenced by the increasing focus on reducing carbon emissions and improving energy efficiency in industrial processes. As a result, manufacturers are investing in research and development to create innovative products that meet the evolving needs of different industries. Overall, the global vacuum-formed ceramic fiber market is poised for significant growth, driven by technological advancements and the increasing demand for high-performance insulation materials.

| Report Metric | Details |

| Report Name | Vacuum Formed Ceramic Fiber Market |

| Accounted market size in year | US$ 480 million |

| Forecasted market size in 2031 | US$ 795 million |

| CAGR | 7.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Termo Refractaires, REFSOURCE, Unifrax, IMS Insulation, McNeil USA, Ates Tugla, Danser, Höganäs Borgestad, ENSAVE, McNeil, Varsha Refractories, Luyang Energy-Saving Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |