What is Global Calcium Silicates for High-temperature Insulation Market?

The Global Calcium Silicates for High-temperature Insulation Market is a specialized segment within the broader insulation industry, focusing on materials that can withstand extreme temperatures. Calcium silicate is a compound used primarily for its insulating properties, especially in environments where high heat resistance is crucial. This market is driven by the demand for efficient thermal insulation solutions in various industries, including construction, petrochemical, and power generation. The material's ability to resist high temperatures makes it ideal for applications where traditional insulation materials might fail. As industries continue to seek ways to improve energy efficiency and reduce heat loss, the demand for high-temperature insulation solutions like calcium silicate is expected to grow. This market is characterized by continuous innovation, with manufacturers striving to enhance the performance and durability of calcium silicate products to meet the evolving needs of their clients. The global market for calcium silicates is not only about providing insulation but also about ensuring safety and efficiency in high-temperature operations. As such, it plays a critical role in supporting industrial processes that require reliable and effective thermal management solutions.

Low Density Calcium Silicate, Medium Density Calcium Silicate, High Density Calcium Silicate in the Global Calcium Silicates for High-temperature Insulation Market:

Low Density Calcium Silicate, Medium Density Calcium Silicate, and High Density Calcium Silicate are three distinct types of calcium silicate materials used in the Global Calcium Silicates for High-temperature Insulation Market, each serving specific purposes based on their density and thermal properties. Low Density Calcium Silicate is typically used in applications where lightweight insulation is crucial. Its low density makes it ideal for situations where reducing the overall weight of the insulation system is important, such as in certain construction or industrial applications. This type of calcium silicate is often used in environments where moderate thermal insulation is needed, and its lightweight nature allows for easier handling and installation. Medium Density Calcium Silicate, on the other hand, offers a balance between weight and thermal performance. It is commonly used in applications where a moderate level of insulation is required, but where the material's weight is not as critical a factor as in low-density applications. Medium density calcium silicate is often employed in industrial settings where it provides reliable thermal insulation while maintaining a manageable weight. This makes it a versatile choice for a wide range of high-temperature insulation needs. High Density Calcium Silicate is designed for applications that demand maximum thermal insulation and durability. Its high density provides superior thermal resistance, making it suitable for the most demanding high-temperature environments. This type of calcium silicate is often used in industries such as petrochemical and power generation, where extreme temperatures are common, and reliable insulation is essential for both safety and efficiency. High density calcium silicate is known for its robustness and ability to withstand harsh conditions, making it a preferred choice for critical applications. Each of these types of calcium silicate materials plays a vital role in the global market for high-temperature insulation, catering to the diverse needs of industries that require effective thermal management solutions. By offering a range of densities and thermal properties, manufacturers can provide tailored solutions that meet the specific requirements of their clients, ensuring optimal performance and safety in high-temperature operations.

Industrial, Petrochemical, Energy & Power in the Global Calcium Silicates for High-temperature Insulation Market:

The usage of Global Calcium Silicates for High-temperature Insulation Market in industrial, petrochemical, and energy & power sectors is extensive and varied, reflecting the material's versatility and effectiveness in managing high temperatures. In the industrial sector, calcium silicate is widely used for insulating equipment and piping systems that operate at high temperatures. Its ability to withstand extreme heat makes it an ideal choice for industries such as steel manufacturing, where furnaces and kilns require reliable insulation to maintain efficiency and safety. By reducing heat loss and improving thermal efficiency, calcium silicate helps industrial operations save energy and reduce costs. In the petrochemical industry, calcium silicate plays a crucial role in insulating equipment used in the processing and refining of chemicals and fuels. The high temperatures involved in petrochemical processes necessitate the use of materials that can provide effective thermal insulation while also being resistant to chemical exposure. Calcium silicate's durability and resistance to chemical attack make it a preferred choice for insulating reactors, heat exchangers, and other critical equipment in petrochemical plants. In the energy & power sector, calcium silicate is used to insulate boilers, turbines, and other equipment that operate at high temperatures. The material's ability to provide reliable thermal insulation helps power plants improve efficiency and reduce energy consumption. By minimizing heat loss, calcium silicate contributes to the overall performance and sustainability of power generation facilities. Additionally, its fire-resistant properties enhance safety in environments where high temperatures and flammable materials are present. Overall, the use of calcium silicate in these sectors highlights its importance as a high-temperature insulation material. Its ability to provide effective thermal management, combined with its durability and resistance to harsh conditions, makes it an essential component in industries that rely on efficient and safe operations. As these industries continue to evolve and seek ways to improve energy efficiency and reduce environmental impact, the demand for high-quality insulation materials like calcium silicate is expected to grow.

Global Calcium Silicates for High-temperature Insulation Market Outlook:

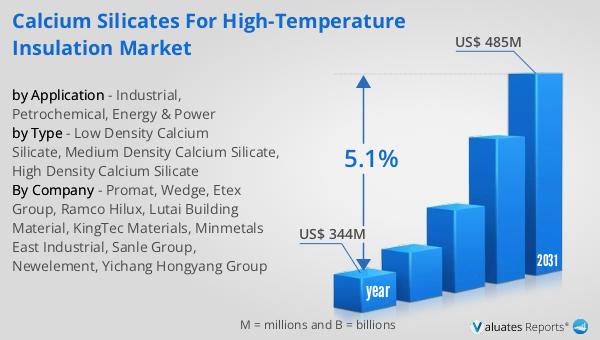

The global market for Calcium Silicates for High-temperature Insulation was valued at $344 million in 2024, and it is anticipated to expand to a revised size of $485 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth trajectory underscores the increasing demand for high-temperature insulation solutions across various industries. As industries continue to prioritize energy efficiency and safety, the need for reliable and effective insulation materials like calcium silicate is expected to rise. The projected growth in the market value indicates a robust demand for these materials, driven by their ability to withstand extreme temperatures and provide effective thermal management. The market's expansion is also likely to be supported by ongoing innovations in product development, as manufacturers strive to enhance the performance and durability of calcium silicate products. As a result, the global market for calcium silicates is poised to play a critical role in supporting industrial processes that require reliable and efficient thermal insulation solutions. This growth not only reflects the increasing importance of high-temperature insulation in various sectors but also highlights the potential for further advancements in the field.

| Report Metric | Details |

| Report Name | Calcium Silicates for High-temperature Insulation Market |

| Accounted market size in year | US$ 344 million |

| Forecasted market size in 2031 | US$ 485 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Promat, Wedge, Etex Group, Ramco Hilux, Lutai Building Material, KingTec Materials, Minmetals East Industrial, Sanle Group, Newelement, Yichang Hongyang Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |