What is Global Sintered Porous Filter Market?

The Global Sintered Porous Filter Market is a specialized segment within the broader filtration industry, focusing on filters made from sintered materials. These filters are created by fusing powdered materials, such as metals or plastics, under heat and pressure to form a solid structure with interconnected pores. This unique manufacturing process results in filters that are highly durable, resistant to high temperatures, and capable of withstanding corrosive environments. The sintered porous filters are used in various applications due to their ability to provide precise filtration, ensuring that even the smallest particles are effectively removed from liquids or gases. Industries such as water treatment, pharmaceuticals, petrochemicals, and food and beverage processing rely on these filters for their critical operations. The market for sintered porous filters is driven by the increasing demand for efficient and reliable filtration solutions across these industries. As environmental regulations become more stringent and the need for clean and safe products grows, the demand for advanced filtration technologies like sintered porous filters is expected to rise. The market is characterized by continuous innovation, with manufacturers focusing on developing filters with enhanced performance characteristics to meet the evolving needs of various industries.

Cartridge Sintered Porous Filter, Disc Sintered Porous Filter, Cup Sintered Porous Filter, Lid Sintered Porous Filter in the Global Sintered Porous Filter Market:

Cartridge Sintered Porous Filters are cylindrical filters that are widely used in various industries for their excellent filtration capabilities. These filters are designed to fit into standard filter housings, making them easy to install and replace. They are commonly used in applications where high flow rates and low-pressure drops are essential. The cartridge design allows for a large surface area, which enhances the filter's ability to capture contaminants. Disc Sintered Porous Filters, on the other hand, are flat, circular filters that are often used in applications requiring precise filtration. These filters are ideal for situations where space is limited, and they can be easily integrated into existing systems. The disc design provides uniform filtration across the entire surface, ensuring consistent performance. Cup Sintered Porous Filters are shaped like a cup and are typically used in applications where the filter needs to be submerged in a liquid. This design is particularly useful in situations where the filter must withstand high pressures and temperatures. The cup shape allows for a large volume of liquid to be filtered, making it suitable for high-capacity applications. Lid Sintered Porous Filters are designed to cover or cap a container, providing filtration at the point of entry or exit. These filters are often used in applications where it is essential to prevent contaminants from entering or leaving a system. The lid design ensures a tight seal, preventing any bypass of unfiltered material. Each of these filter types offers unique advantages, making them suitable for specific applications within the Global Sintered Porous Filter Market. Manufacturers continue to innovate and improve these designs to meet the growing demands of various industries. The versatility and reliability of sintered porous filters make them an essential component in many industrial processes, ensuring the purity and quality of products and processes.

Water Treatment, Petroleum and Chemical, Pharmaceutical, Others in the Global Sintered Porous Filter Market:

The Global Sintered Porous Filter Market plays a crucial role in several key industries, including water treatment, petroleum and chemical, pharmaceutical, and others. In water treatment, sintered porous filters are used to remove impurities and contaminants from water, ensuring it is safe for consumption and use. These filters are highly effective in removing particles, bacteria, and other harmful substances, making them essential for municipal water treatment plants, industrial water purification systems, and residential water filtration units. In the petroleum and chemical industries, sintered porous filters are used to purify and separate fluids and gases. They are capable of withstanding harsh chemical environments and high temperatures, making them ideal for use in refineries, chemical processing plants, and oil and gas extraction operations. These filters help ensure the purity of products and protect equipment from damage caused by contaminants. In the pharmaceutical industry, sintered porous filters are used to maintain the sterility and purity of products. They are used in the production of drugs, vaccines, and other pharmaceutical products to remove contaminants and ensure the safety and efficacy of the final product. The filters are also used in laboratory settings for research and development purposes. Other industries that benefit from sintered porous filters include food and beverage processing, electronics manufacturing, and automotive production. In these industries, the filters are used to ensure the quality and safety of products, protect equipment, and improve process efficiency. The versatility and reliability of sintered porous filters make them an essential component in many industrial processes, contributing to the overall growth and development of the Global Sintered Porous Filter Market.

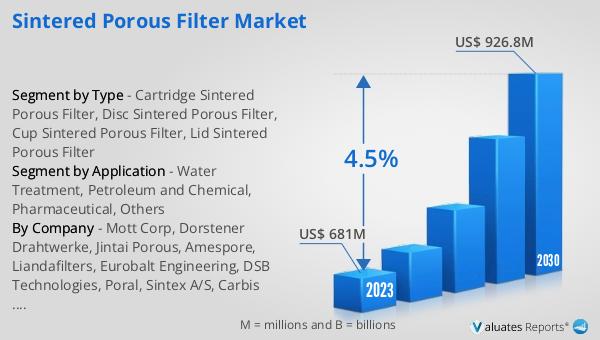

Global Sintered Porous Filter Market Outlook:

The global market for sintered porous filters was valued at $740 million in 2024 and is anticipated to expand to a revised size of $1,003 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth is driven by the increasing demand for efficient and reliable filtration solutions across various industries. As environmental regulations become more stringent and the need for clean and safe products grows, the demand for advanced filtration technologies like sintered porous filters is expected to rise. The market is characterized by continuous innovation, with manufacturers focusing on developing filters with enhanced performance characteristics to meet the evolving needs of various industries. The versatility and reliability of sintered porous filters make them an essential component in many industrial processes, ensuring the purity and quality of products and processes. The market is expected to continue its growth trajectory as industries seek to improve their filtration capabilities and meet the demands of an increasingly regulated and competitive global market.

| Report Metric | Details |

| Report Name | Sintered Porous Filter Market |

| Accounted market size in year | US$ 740 million |

| Forecasted market size in 2031 | US$ 1003 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mott Corp, Dorstener Drahtwerke, Jintai Porous, Amespore, Liandafilters, Eurobalt Engineering, DSB Technologies, Poral, Sintex A/S, Carbis Filtration Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |