What is Global Heat Insulation Ceramic Fiber Paper Market?

The Global Heat Insulation Ceramic Fiber Paper Market is a specialized segment within the broader insulation materials industry, focusing on the production and distribution of ceramic fiber paper designed for heat insulation purposes. This market is characterized by its unique product offerings that cater to industries requiring high-temperature insulation solutions. Ceramic fiber paper is a lightweight, flexible material made from high-purity aluminosilicate fibers, which are known for their excellent thermal stability and low thermal conductivity. These properties make it an ideal choice for applications where heat resistance is crucial. The market is driven by the increasing demand for energy-efficient solutions across various industries, including construction, aerospace, petrochemical, and automotive. As industries strive to improve energy efficiency and reduce carbon footprints, the demand for effective insulation materials like ceramic fiber paper is expected to grow. Additionally, advancements in manufacturing technologies have enabled the production of ceramic fiber paper with enhanced properties, further boosting its adoption. The market is also influenced by regulatory standards and environmental concerns, which encourage the use of sustainable and non-toxic insulation materials. Overall, the Global Heat Insulation Ceramic Fiber Paper Market plays a vital role in supporting industries that require reliable and efficient thermal management solutions.

1mm, 2mm, 3mm, Others in the Global Heat Insulation Ceramic Fiber Paper Market:

In the Global Heat Insulation Ceramic Fiber Paper Market, the thickness of the paper plays a crucial role in determining its suitability for various applications. The market offers ceramic fiber paper in different thicknesses, including 1mm, 2mm, 3mm, and other variations, each catering to specific needs. The 1mm ceramic fiber paper is typically used in applications where space is limited, and a thin layer of insulation is sufficient. Its lightweight and flexible nature make it ideal for wrapping pipes, lining ducts, and insulating small components in high-temperature environments. The 2mm ceramic fiber paper, on the other hand, provides a balance between thickness and flexibility, making it suitable for a wider range of applications. It is often used in the construction industry for insulating walls, roofs, and floors, as well as in the automotive sector for heat shields and gaskets. The 3mm ceramic fiber paper offers enhanced insulation properties due to its increased thickness, making it ideal for applications requiring higher thermal resistance. It is commonly used in the aerospace industry for insulating aircraft components and in the petrochemical industry for lining furnaces and kilns. Other thickness variations are available to meet specific requirements, such as custom insulation solutions for specialized equipment or machinery. The choice of thickness depends on factors such as the operating temperature, space constraints, and the level of insulation required. Manufacturers in the Global Heat Insulation Ceramic Fiber Paper Market continuously innovate to develop products with improved thermal performance, durability, and ease of installation. This includes advancements in fiber composition, binder systems, and manufacturing processes to enhance the overall quality and effectiveness of the insulation paper. As industries continue to seek energy-efficient solutions, the demand for ceramic fiber paper in various thicknesses is expected to grow, driven by the need for reliable and efficient thermal management across diverse applications.

Construction, Aerospace, Petrochemical, Automotive, Others in the Global Heat Insulation Ceramic Fiber Paper Market:

The Global Heat Insulation Ceramic Fiber Paper Market finds extensive usage across various industries, including construction, aerospace, petrochemical, automotive, and others, due to its exceptional thermal insulation properties. In the construction industry, ceramic fiber paper is used to insulate walls, roofs, and floors, helping to maintain comfortable indoor temperatures and reduce energy consumption. Its lightweight and flexible nature make it easy to install, even in complex architectural designs. In the aerospace sector, ceramic fiber paper is used to insulate aircraft components, such as engines and exhaust systems, where high-temperature resistance is crucial. Its ability to withstand extreme temperatures without degrading ensures the safety and efficiency of aerospace operations. The petrochemical industry relies on ceramic fiber paper for lining furnaces, kilns, and reactors, where it provides excellent thermal insulation and helps maintain optimal operating temperatures. Its resistance to chemical corrosion and thermal shock makes it a reliable choice for harsh industrial environments. In the automotive industry, ceramic fiber paper is used in heat shields, gaskets, and exhaust systems to protect components from heat damage and improve vehicle performance. Its lightweight nature contributes to overall vehicle weight reduction, enhancing fuel efficiency. Other industries, such as power generation and metallurgy, also benefit from the use of ceramic fiber paper for insulation purposes. Its versatility and adaptability make it suitable for a wide range of applications, from insulating small components to lining large industrial equipment. As industries continue to prioritize energy efficiency and sustainability, the demand for ceramic fiber paper is expected to grow, driven by its ability to provide effective thermal management solutions across diverse applications.

Global Heat Insulation Ceramic Fiber Paper Market Outlook:

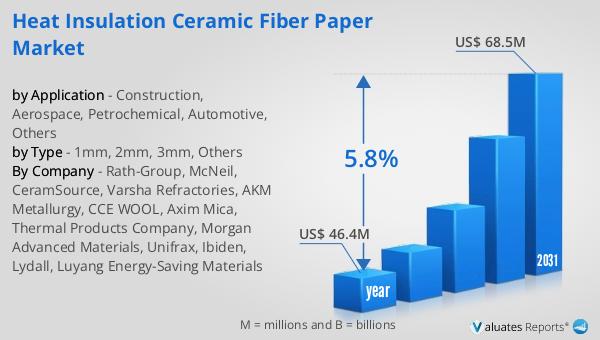

The global market for Heat Insulation Ceramic Fiber Paper was valued at US$ 46.4 million in 2024 and is anticipated to expand to a revised size of US$ 68.5 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period. This growth trajectory underscores the increasing demand for ceramic fiber paper as industries seek efficient thermal insulation solutions to enhance energy efficiency and reduce operational costs. The market's expansion is driven by the rising adoption of ceramic fiber paper across various sectors, including construction, aerospace, petrochemical, and automotive, where its exceptional thermal properties are highly valued. As industries continue to focus on sustainability and energy conservation, the demand for advanced insulation materials like ceramic fiber paper is expected to rise. The market's growth is also supported by technological advancements in manufacturing processes, which have led to the development of ceramic fiber paper with improved performance characteristics. These innovations have expanded the range of applications for ceramic fiber paper, further boosting its market potential. Overall, the Global Heat Insulation Ceramic Fiber Paper Market is poised for significant growth, driven by the increasing need for effective thermal management solutions across diverse industries.

| Report Metric | Details |

| Report Name | Heat Insulation Ceramic Fiber Paper Market |

| Accounted market size in year | US$ 46.4 million |

| Forecasted market size in 2031 | US$ 68.5 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rath-Group, McNeil, CeramSource, Varsha Refractories, AKM Metallurgy, CCE WOOL, Axim Mica, Thermal Products Company, Morgan Advanced Materials, Unifrax, Ibiden, Lydall, Luyang Energy-Saving Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |