What is Global Zinc Aluminium Magnesium Cotated Steel Market?

The Global Zinc Aluminium Magnesium Coated Steel Market is a specialized segment of the steel industry that focuses on the production and distribution of steel coated with a unique alloy of zinc, aluminum, and magnesium. This coating enhances the steel's resistance to corrosion, making it an ideal choice for various applications where durability and longevity are crucial. The combination of these metals in the coating provides superior protection compared to traditional galvanized steel, offering improved performance in harsh environments. This market is driven by the increasing demand for high-performance materials in industries such as construction, automotive, and electronics. The coated steel is particularly valued for its ability to withstand extreme weather conditions, resist rust, and maintain structural integrity over time. As industries continue to seek materials that offer both strength and resilience, the demand for zinc aluminum magnesium coated steel is expected to grow, making it a significant player in the global steel market. The market's growth is also supported by advancements in coating technologies and the development of new applications that leverage the unique properties of this coated steel.

Medium-aluminum Zn-Al-Mg Coated Steel, Low-aluminum Zn-Al-Mg Coated Steel, High-aluminum Zn-Al-Mg Coated Steel in the Global Zinc Aluminium Magnesium Cotated Steel Market:

Medium-aluminum Zn-Al-Mg coated steel is a versatile material that strikes a balance between cost and performance, making it a popular choice in the Global Zinc Aluminium Magnesium Coated Steel Market. This type of coated steel contains a moderate amount of aluminum, which enhances its corrosion resistance while maintaining affordability. It is widely used in construction, automotive, and industrial applications where durability is essential but cost constraints are also a consideration. The medium-aluminum variant offers a good compromise between the high corrosion resistance of high-aluminum coatings and the cost-effectiveness of low-aluminum coatings. On the other hand, low-aluminum Zn-Al-Mg coated steel is designed for applications where cost is a primary concern, and the environment is less corrosive. This variant contains a lower percentage of aluminum, which reduces the overall cost of the coating. While it may not offer the same level of corrosion resistance as its medium or high-aluminum counterparts, it is still a viable option for indoor applications or environments with minimal exposure to corrosive elements. It is often used in consumer electronics, indoor construction, and other areas where the risk of corrosion is relatively low. High-aluminum Zn-Al-Mg coated steel, meanwhile, is engineered for maximum corrosion resistance, making it suitable for the most demanding environments. This variant contains a higher percentage of aluminum, which significantly enhances its ability to withstand harsh conditions, such as marine environments or industrial settings with high levels of pollution. The high-aluminum coating provides superior protection against rust and degradation, ensuring the longevity and reliability of the steel in challenging applications. It is often used in infrastructure projects, automotive components exposed to road salts, and other critical applications where failure is not an option. Each of these variants plays a crucial role in the Global Zinc Aluminium Magnesium Coated Steel Market, catering to different needs and preferences across various industries. The choice between medium, low, and high-aluminum coatings depends on factors such as budget, environmental conditions, and specific performance requirements. As industries continue to evolve and demand more specialized materials, the market for these coated steel variants is expected to grow, driven by the need for materials that offer both performance and cost-effectiveness. The ongoing development of new coating technologies and the exploration of new applications will further expand the possibilities for Zn-Al-Mg coated steel, solidifying its position as a key material in the global market.

Architecture Industrial, Automobile Industrial, Electronics Industrial, Others in the Global Zinc Aluminium Magnesium Cotated Steel Market:

The Global Zinc Aluminium Magnesium Coated Steel Market finds extensive usage across various industries, each benefiting from the unique properties of this advanced material. In the architecture industry, this coated steel is prized for its exceptional durability and aesthetic appeal. It is commonly used in roofing, cladding, and structural components, where its resistance to corrosion ensures long-lasting performance even in harsh weather conditions. The material's ability to maintain its appearance over time makes it an attractive choice for architects and builders looking to create structures that are both functional and visually appealing. In the industrial sector, zinc aluminum magnesium coated steel is utilized for its strength and resilience. It is often employed in the manufacturing of machinery, equipment, and storage facilities, where its ability to withstand wear and tear is crucial. The material's resistance to rust and corrosion extends the lifespan of industrial products, reducing maintenance costs and downtime. In the automotive industry, this coated steel is used in the production of various components, including body panels, chassis, and underbody parts. Its lightweight nature, combined with its strength and corrosion resistance, makes it an ideal choice for automotive manufacturers looking to improve fuel efficiency and vehicle longevity. The electronics industry also benefits from the use of zinc aluminum magnesium coated steel, particularly in the production of enclosures and casings for electronic devices. The material's ability to protect sensitive components from environmental factors such as moisture and dust is essential for ensuring the reliability and performance of electronic products. Additionally, the coated steel's electromagnetic shielding properties make it suitable for use in devices that require protection from electromagnetic interference. Beyond these industries, zinc aluminum magnesium coated steel is also used in various other applications, including agriculture, transportation, and energy. Its versatility and performance make it a valuable material for any application where durability and resistance to environmental factors are critical. As industries continue to seek materials that offer both performance and sustainability, the demand for zinc aluminum magnesium coated steel is expected to grow, driven by its ability to meet the evolving needs of modern applications.

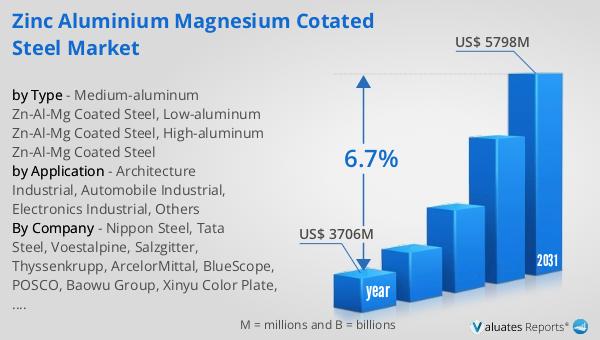

Global Zinc Aluminium Magnesium Cotated Steel Market Outlook:

The global market for Zinc Aluminium Magnesium Coated Steel was valued at $3,706 million in 2024 and is anticipated to expand to a revised size of $5,798 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.7% during the forecast period. Nippon Steel and ArcelorMittal are the leading companies in this market, collectively accounting for over 60% of the global market share. Geographically, Japan dominates the market, holding over 40% of the total market share. In terms of aluminum content, medium-aluminum Zn-Al-Mg coated steel represents more than 50% of the total market share. When considering product applications, the architecture industrial segment is the largest, comprising over 60% of the total market share. This market outlook highlights the significant role of zinc aluminum magnesium coated steel in various industries and regions, driven by its superior performance characteristics and the growing demand for durable, corrosion-resistant materials. As the market continues to evolve, the focus on innovation and the development of new applications will be crucial in maintaining the growth trajectory and meeting the diverse needs of industries worldwide.

| Report Metric | Details |

| Report Name | Zinc Aluminium Magnesium Cotated Steel Market |

| Accounted market size in year | US$ 3706 million |

| Forecasted market size in 2031 | US$ 5798 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nippon Steel, Tata Steel, Voestalpine, Salzgitter, Thyssenkrupp, ArcelorMittal, BlueScope, POSCO, Baowu Group, Xinyu Color Plate, Jiuquan Iron & Steel Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |