What is Global Wet Magnetic Drum Separators Market?

The Global Wet Magnetic Drum Separators Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to separate magnetic materials from non-magnetic ones in a wet environment. These separators are crucial in various industries, including mining, recycling, and manufacturing, where they help in the efficient processing of materials by removing ferrous contaminants. The market for these separators is driven by the increasing demand for high-quality, pure materials and the need for efficient waste management solutions. Wet magnetic drum separators are preferred over dry separators in certain applications due to their ability to handle fine particles and slurries, which are common in mining and mineral processing. The market is characterized by technological advancements aimed at improving the efficiency and capacity of these separators, as well as by the growing emphasis on sustainability and environmental protection. As industries continue to seek ways to optimize their processes and reduce waste, the demand for wet magnetic drum separators is expected to grow, making this market an important area of focus for manufacturers and investors alike.

Drum Type Drum Separators, Cross-belt Drum Separators, Roller Drum Separators in the Global Wet Magnetic Drum Separators Market:

Drum Type Drum Separators, Cross-belt Drum Separators, and Roller Drum Separators are three distinct types of equipment within the Global Wet Magnetic Drum Separators Market, each serving unique functions and applications. Drum Type Drum Separators are the most common and widely used type, known for their simplicity and effectiveness in separating magnetic materials from non-magnetic ones. They consist of a rotating drum with a fixed magnet inside, which attracts and holds magnetic particles as the drum rotates. This type of separator is particularly effective in handling large volumes of material and is often used in mining and mineral processing industries where the separation of ferrous materials from ores is crucial. The design of Drum Type Drum Separators allows for continuous operation, making them highly efficient and cost-effective for large-scale operations. Cross-belt Drum Separators, on the other hand, are designed to handle materials that are transported on a conveyor belt. These separators use a cross-belt system to remove magnetic particles from the material stream. The cross-belt design allows for the separation of materials without interrupting the flow of the conveyor, making it ideal for applications where continuous processing is required. Cross-belt Drum Separators are commonly used in recycling and waste management industries, where they help in the recovery of valuable ferrous materials from mixed waste streams. The ability to integrate these separators into existing conveyor systems makes them a versatile and efficient solution for many industrial applications. Roller Drum Separators are another type of wet magnetic separator, characterized by their use of rollers to separate magnetic materials. These separators are particularly effective in handling fine particles and slurries, making them ideal for applications in the mining and mineral processing industries. The roller design allows for precise control over the separation process, ensuring that even the smallest magnetic particles are effectively removed from the material stream. Roller Drum Separators are often used in conjunction with other types of separators to achieve the highest levels of purity and efficiency in material processing. The choice between Drum Type, Cross-belt, and Roller Drum Separators depends on the specific requirements of the application, including the type of material being processed, the desired level of purity, and the operational constraints of the facility. Each type of separator offers unique advantages and can be customized to meet the specific needs of different industries. As the demand for high-quality materials and efficient waste management solutions continues to grow, the market for these separators is expected to expand, driven by technological advancements and the increasing emphasis on sustainability and environmental protection.

Mining Industry, Architecture and Engineering, Recycling Industry, Others in the Global Wet Magnetic Drum Separators Market:

The Global Wet Magnetic Drum Separators Market finds extensive usage across various industries, including the Mining Industry, Architecture and Engineering, Recycling Industry, and others. In the Mining Industry, wet magnetic drum separators are essential for the extraction and processing of minerals. They are used to separate valuable ferrous minerals from non-ferrous materials, ensuring the purity and quality of the extracted ores. This process is crucial for the production of metals such as iron, nickel, and cobalt, which are used in a wide range of applications, from construction to electronics. The ability of wet magnetic drum separators to handle fine particles and slurries makes them particularly suitable for mining operations, where the efficient processing of materials is critical to profitability. In the field of Architecture and Engineering, wet magnetic drum separators play a role in the production of construction materials. They are used to remove ferrous contaminants from raw materials such as sand, gravel, and cement, ensuring the quality and durability of the final products. This is particularly important in the construction of buildings and infrastructure, where the presence of impurities can compromise the structural integrity of the materials. The use of wet magnetic drum separators in this industry helps to ensure that construction materials meet the required standards and specifications, contributing to the safety and longevity of buildings and infrastructure. The Recycling Industry is another major user of wet magnetic drum separators, where they are employed to recover valuable ferrous materials from mixed waste streams. These separators are used to separate metals such as steel and iron from other materials, allowing for their reuse and recycling. This not only helps to reduce waste and conserve natural resources but also provides a source of revenue for recycling companies. The ability of wet magnetic drum separators to handle a wide range of materials and operate continuously makes them an ideal solution for recycling operations, where efficiency and cost-effectiveness are key considerations. In addition to these industries, wet magnetic drum separators are also used in various other applications, including the processing of food and pharmaceuticals, the treatment of wastewater, and the production of chemicals. In the food and pharmaceutical industries, these separators are used to remove ferrous contaminants from raw materials, ensuring the safety and quality of the final products. In wastewater treatment, they are used to remove metal particles from sludge, helping to prevent pollution and protect the environment. The versatility and effectiveness of wet magnetic drum separators make them a valuable tool in a wide range of industrial applications, contributing to the efficiency and sustainability of processes across different sectors.

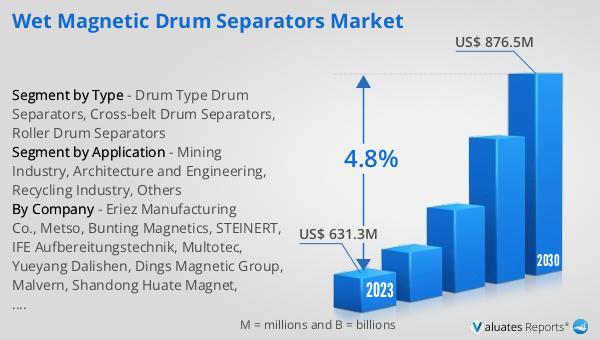

Global Wet Magnetic Drum Separators Market Outlook:

The global market for Wet Magnetic Drum Separators, valued at $690 million in 2024, is anticipated to grow significantly, reaching an estimated size of $954 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.8% over the forecast period. This upward trajectory reflects the increasing demand for efficient and effective separation technologies across various industries. The growth of this market is driven by several factors, including the rising need for high-quality materials, the emphasis on sustainable and environmentally friendly practices, and the continuous advancements in technology that enhance the performance and efficiency of these separators. As industries such as mining, recycling, and manufacturing continue to expand and evolve, the demand for wet magnetic drum separators is expected to increase, providing opportunities for manufacturers and investors in this market. The projected growth of the market underscores the importance of these separators in modern industrial processes, where the efficient separation of materials is crucial to optimizing production and reducing waste. As the market continues to grow, it is likely to see further innovations and developments that will enhance the capabilities and applications of wet magnetic drum separators, making them an even more integral part of industrial operations worldwide.

| Report Metric | Details |

| Report Name | Wet Magnetic Drum Separators Market |

| Accounted market size in year | US$ 690 million |

| Forecasted market size in 2031 | US$ 954 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eriez Manufacturing Co., Metso, Bunting Magnetics, STEINERT, IFE Aufbereitungstechnik, Multotec, Yueyang Dalishen, Dings Magnetic Group, Malvern, Shandong Huate Magnet, HANKOOK MATICS CO., LTD (HKM) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |