What is Global Co-Processed Excipients Market?

The Global Co-Processed Excipients Market refers to a specialized segment within the pharmaceutical and nutraceutical industries that focuses on the development and utilization of excipients. Excipients are inactive substances used as carriers for the active ingredients of a medication. Co-processed excipients are created by combining two or more excipients to enhance their functionality and performance in drug formulation. This market is driven by the need for improved drug delivery systems, which require excipients that can enhance the solubility, stability, and bioavailability of active pharmaceutical ingredients (APIs). The demand for co-processed excipients is increasing due to their ability to simplify the manufacturing process, improve the quality of the final product, and reduce production costs. These excipients are used in various dosage forms, including tablets, capsules, and powders, and are essential for ensuring the efficacy and safety of medications. The market is characterized by continuous innovation and research to develop new excipient combinations that meet the evolving needs of the pharmaceutical industry. As the demand for more efficient and effective drug delivery systems grows, the Global Co-Processed Excipients Market is expected to expand, offering new opportunities for manufacturers and suppliers.

Granulation, Spray Drying, Hot Melt Extrusion, Solvent Evaporation, Others in the Global Co-Processed Excipients Market:

Granulation, spray drying, hot melt extrusion, solvent evaporation, and other techniques are pivotal in the Global Co-Processed Excipients Market, each offering unique advantages and applications. Granulation is a process that involves the aggregation of powder particles to form larger, multi-particle entities called granules. This technique is essential for improving the flowability and compressibility of powders, making it easier to produce tablets with uniform weight and content. Granulation can be achieved through wet or dry methods, with wet granulation involving the addition of a liquid binder to form granules, while dry granulation uses pressure to compact the powder. Spray drying, on the other hand, is a method used to produce a dry powder from a liquid or slurry by rapidly drying it with a hot gas. This technique is particularly useful for creating co-processed excipients with enhanced solubility and dispersibility, as it allows for the production of fine, uniform particles that dissolve quickly in liquid. Hot melt extrusion is a process that involves the melting and shaping of materials through the application of heat and pressure. This technique is used to produce co-processed excipients with improved mechanical properties, such as increased strength and flexibility, making them suitable for use in various dosage forms. Solvent evaporation is a method used to remove solvents from a solution or suspension, leaving behind a solid product. This technique is often used in the production of co-processed excipients to enhance the stability and shelf life of the final product. Other techniques used in the Global Co-Processed Excipients Market include co-precipitation, lyophilization, and supercritical fluid processing, each offering unique benefits and applications. Co-precipitation involves the simultaneous precipitation of two or more components from a solution, resulting in a homogeneous mixture with improved functionality. Lyophilization, also known as freeze-drying, is a process that removes water from a product by freezing it and then sublimating the ice under vacuum. This technique is used to produce co-processed excipients with enhanced stability and solubility. Supercritical fluid processing involves the use of supercritical fluids, such as carbon dioxide, to extract or modify materials, resulting in co-processed excipients with improved purity and performance. Each of these techniques plays a crucial role in the development and production of co-processed excipients, offering unique advantages and applications that contribute to the growth and innovation of the Global Co-Processed Excipients Market.

Pharmaceuticals, Nutraceuticals in the Global Co-Processed Excipients Market:

The Global Co-Processed Excipients Market plays a significant role in the pharmaceutical and nutraceutical industries, providing essential components for the formulation of various products. In the pharmaceutical industry, co-processed excipients are used to enhance the performance and efficacy of medications. They are essential for improving the solubility, stability, and bioavailability of active pharmaceutical ingredients (APIs), ensuring that medications are effective and safe for patients. Co-processed excipients are used in a wide range of dosage forms, including tablets, capsules, and powders, and are crucial for ensuring the uniformity and quality of the final product. They also help to simplify the manufacturing process, reduce production costs, and improve the overall efficiency of drug production. In the nutraceutical industry, co-processed excipients are used to enhance the quality and performance of dietary supplements and functional foods. They are essential for improving the solubility, stability, and bioavailability of active ingredients, ensuring that consumers receive the full benefits of the product. Co-processed excipients are used in various forms, including tablets, capsules, and powders, and are crucial for ensuring the uniformity and quality of the final product. They also help to simplify the manufacturing process, reduce production costs, and improve the overall efficiency of nutraceutical production. The demand for co-processed excipients in the nutraceutical industry is driven by the growing consumer interest in health and wellness products, as well as the increasing demand for more effective and efficient delivery systems. As the pharmaceutical and nutraceutical industries continue to evolve, the Global Co-Processed Excipients Market is expected to expand, offering new opportunities for manufacturers and suppliers.

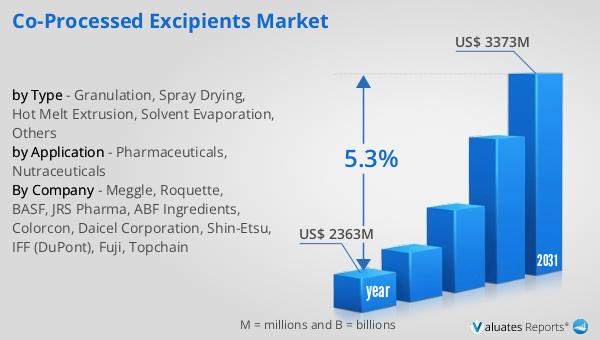

Global Co-Processed Excipients Market Outlook:

The worldwide market for co-processed excipients was valued at approximately $2,363 million in 2024 and is anticipated to grow to around $3,373 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.3% over the forecast period. The industry for co-processed excipients is characterized by a low level of market concentration, with the top five companies accounting for less than 30% of the global market share. In terms of the types of co-processed excipients, spray drying holds a significant portion, commanding over 55% of the market, while granulation accounts for nearly 20%. This distribution highlights the dominance of spray drying as a preferred method in the production of co-processed excipients, likely due to its ability to produce fine, uniform particles that enhance the solubility and dispersibility of active ingredients. The relatively low market concentration suggests a competitive landscape with numerous players contributing to the market dynamics. This competitive environment may foster innovation and the development of new excipient combinations to meet the evolving needs of the pharmaceutical and nutraceutical industries. As the demand for more efficient and effective drug delivery systems continues to grow, the Global Co-Processed Excipients Market is poised for further expansion, offering new opportunities for manufacturers and suppliers to capitalize on this growth.

| Report Metric | Details |

| Report Name | Co-Processed Excipients Market |

| Accounted market size in year | US$ 2363 million |

| Forecasted market size in 2031 | US$ 3373 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Meggle, Roquette, BASF, JRS Pharma, ABF Ingredients, Colorcon, Daicel Corporation, Shin-Etsu, IFF (DuPont), Fuji, Topchain |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |