What is Global Household Appliances Color-Coated Sheet Market?

The Global Household Appliances Color-Coated Sheet Market is a specialized segment within the broader steel and coatings industry, focusing on the production and distribution of color-coated sheets used in household appliances. These sheets are primarily made from steel and are coated with a layer of paint or film to enhance their aesthetic appeal and provide protection against corrosion. The market is driven by the increasing demand for aesthetically pleasing and durable household appliances, as consumers seek products that not only perform well but also complement their home decor. The color-coated sheets are used in a variety of appliances, including refrigerators, washing machines, and air conditioners, among others. The market is characterized by technological advancements in coating techniques and materials, which have led to the development of more durable and vibrant color options. Additionally, the market is influenced by trends in home design and consumer preferences, which can vary significantly across different regions. As a result, manufacturers in this market must be agile and responsive to changing consumer demands and technological innovations to maintain their competitive edge.

PCM, VCM in the Global Household Appliances Color-Coated Sheet Market:

PCM (Pre-Coated Metal) and VCM (Vinyl Coated Metal) are two primary types of color-coated sheets used in the Global Household Appliances Color-Coated Sheet Market. PCM involves coating a metal substrate, typically steel, with a layer of paint before it is formed into the final product. This process allows for a wide range of colors and finishes, providing manufacturers with the flexibility to create appliances that meet diverse consumer preferences. PCM is known for its durability, resistance to corrosion, and ability to maintain its color over time, making it a popular choice for appliances that are exposed to varying environmental conditions. On the other hand, VCM involves applying a vinyl film to the metal substrate, which can be printed with intricate patterns and designs. This method offers even greater versatility in terms of aesthetics, as it allows for the creation of appliances with unique and eye-catching designs. VCM is particularly popular in markets where consumers value distinctive and personalized home appliances. Both PCM and VCM have their advantages and are chosen based on the specific requirements of the appliance and the target market. For instance, PCM might be preferred for its robustness and longevity, while VCM could be favored for its design flexibility and visual appeal. The choice between PCM and VCM also depends on factors such as cost, production capabilities, and environmental considerations. Manufacturers must weigh these factors carefully to select the most appropriate coating method for their products. In recent years, there has been a growing emphasis on sustainability in the Global Household Appliances Color-Coated Sheet Market. This has led to the development of eco-friendly coatings and processes that minimize environmental impact while maintaining high performance standards. Both PCM and VCM technologies have evolved to incorporate these sustainable practices, such as using water-based paints and recyclable materials. This shift towards sustainability is driven by increasing consumer awareness and regulatory pressures, which are pushing manufacturers to adopt greener practices. As a result, companies in this market are investing in research and development to create innovative solutions that meet the demands of environmentally conscious consumers. The competition between PCM and VCM is also influenced by regional preferences and market dynamics. In some regions, consumers may prioritize durability and functionality, leading to a preference for PCM-coated appliances. In others, the emphasis may be on design and aesthetics, making VCM the preferred choice. Manufacturers must navigate these regional differences to effectively cater to the diverse needs of the global market. Overall, PCM and VCM are integral components of the Global Household Appliances Color-Coated Sheet Market, each offering unique benefits and challenges. As the market continues to evolve, manufacturers will need to stay abreast of technological advancements and consumer trends to remain competitive. By leveraging the strengths of both PCM and VCM, companies can create innovative and appealing products that meet the needs of today's discerning consumers.

Refrigerator, Washing Machine, Air Conditioning, TV, Audio-video Product, Micro-wave Oven, Water Heater, Others in the Global Household Appliances Color-Coated Sheet Market:

The Global Household Appliances Color-Coated Sheet Market plays a crucial role in the production of various household appliances, providing both functional and aesthetic benefits. In refrigerators, color-coated sheets are used to create sleek and modern exteriors that enhance the overall look of the kitchen. These sheets not only provide a visually appealing finish but also protect the appliance from rust and wear, ensuring longevity. Similarly, in washing machines, color-coated sheets are used to create durable and attractive exteriors that can withstand the rigors of daily use. The coatings help prevent scratches and dents, maintaining the appliance's appearance over time. In air conditioning units, color-coated sheets are used to create stylish and durable casings that blend seamlessly with home interiors. The coatings provide protection against environmental factors such as moisture and UV rays, ensuring the unit's longevity and performance. For televisions and audio-video products, color-coated sheets are used to create sleek and modern designs that complement contemporary home decor. The coatings provide a high-quality finish that enhances the visual appeal of these products. In microwave ovens, color-coated sheets are used to create durable and easy-to-clean exteriors that can withstand high temperatures and frequent use. The coatings help prevent stains and discoloration, ensuring the appliance maintains its appearance over time. Water heaters also benefit from color-coated sheets, which provide a protective and aesthetically pleasing finish. The coatings help prevent corrosion and extend the lifespan of the appliance, ensuring reliable performance. In addition to these specific applications, color-coated sheets are used in a variety of other household appliances, providing both functional and aesthetic benefits. The versatility of these sheets allows manufacturers to create products that meet the diverse needs and preferences of consumers. As a result, the Global Household Appliances Color-Coated Sheet Market continues to grow, driven by the demand for high-quality and visually appealing appliances.

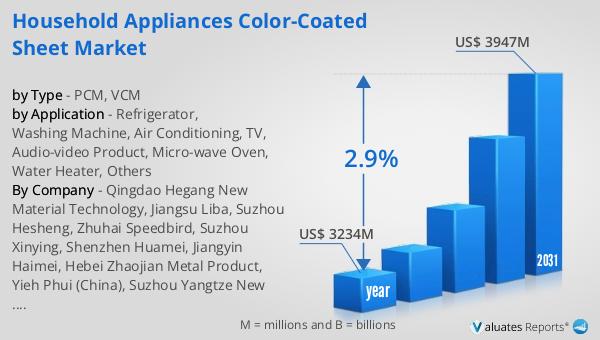

Global Household Appliances Color-Coated Sheet Market Outlook:

The global market for Household Appliances Color-Coated Sheet was valued at $3,234 million in 2024 and is anticipated to expand to a revised size of $3,947 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% over the forecast period. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 35%. Key players in this industry include Qingdao Hegang New Material Technology, Suzhou Hesheng, Jiangsu Liba, Zhuhai Speedbird, and Suzhou Xinying. These companies are at the forefront of innovation and production in the color-coated sheet market, leveraging advanced technologies and materials to meet the evolving demands of consumers. Their strong market presence is a testament to their ability to deliver high-quality products that cater to the diverse needs of the global market. As the market continues to grow, these key players are likely to maintain their competitive edge by investing in research and development, expanding their product offerings, and exploring new markets. The projected growth of the market is indicative of the increasing demand for aesthetically pleasing and durable household appliances, as consumers seek products that enhance their living spaces while providing reliable performance. The market's expansion is also driven by technological advancements in coating techniques and materials, which have led to the development of more durable and vibrant color options. As a result, manufacturers in this market must remain agile and responsive to changing consumer demands and technological innovations to maintain their competitive edge.

| Report Metric | Details |

| Report Name | Household Appliances Color-Coated Sheet Market |

| Accounted market size in year | US$ 3234 million |

| Forecasted market size in 2031 | US$ 3947 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Qingdao Hegang New Material Technology, Jiangsu Liba, Suzhou Hesheng, Zhuhai Speedbird, Suzhou Xinying, Shenzhen Huamei, Jiangyin Haimei, Hebei Zhaojian Metal Product, Yieh Phui (China), Suzhou Yangtze New Materials, Anhui Wonderful-wall Color Coating Aluminium Science, Jiangsu Jiangnan, Dingchuan Shengyu, DK Dongshin, Dongkuk Steel, Dongbu Steel, POSCO, BN STEELA, DCM CORP, SAMYANG METAL, AJU Steel Co Ltd, Lampre, Hanwa Steel, JFE Steel, NSSMC, Shandong Guanzhou, Zhejiang Huada, Jiangsu Zhongwei, Tianjin Xinyu, Tianjin Pipe, Hefei Dadong, Puluofei New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |