What is Global Bio-Soluble Fiber Board Market?

The Global Bio-Soluble Fiber Board Market is an emerging sector within the broader insulation materials industry. Bio-soluble fiber boards are specialized materials designed to provide thermal insulation while being environmentally friendly and safe for human health. Unlike traditional insulation materials, these boards are made from fibers that dissolve in biological fluids, reducing health risks associated with inhalation. This makes them particularly appealing in industries where safety and environmental impact are of significant concern. The market for these boards is driven by increasing demand for sustainable building materials and stringent regulations on occupational health and safety. Industries such as petrochemicals, ceramics, and metallurgy are major consumers, as they require high-temperature insulation solutions that are both effective and safe. The boards are also gaining traction in residential and commercial construction, where energy efficiency and sustainability are becoming key priorities. As awareness of the benefits of bio-soluble fiber boards grows, the market is expected to expand, offering new opportunities for manufacturers and suppliers. The focus on reducing carbon footprints and enhancing safety standards is likely to further propel the adoption of these innovative materials across various sectors.

Silica, Calcium Oxide, Magnesium Oxide, Others in the Global Bio-Soluble Fiber Board Market:

Silica, calcium oxide, magnesium oxide, and other components play crucial roles in the composition and functionality of bio-soluble fiber boards. Silica, a primary component, is valued for its thermal stability and ability to withstand high temperatures, making it an essential ingredient in the production of these boards. It provides the necessary structural integrity and insulation properties that are critical for applications in high-temperature environments. Calcium oxide, another vital component, contributes to the board's ability to resist chemical reactions and maintain its form under extreme conditions. It enhances the board's durability and longevity, ensuring that it can withstand the rigors of industrial applications. Magnesium oxide, known for its fire-resistant properties, adds an extra layer of safety to the boards. It helps in preventing the spread of fire, making the boards suitable for use in environments where fire hazards are a concern. The combination of these components results in a material that is not only effective in insulation but also safe and environmentally friendly. Other materials used in the production of bio-soluble fiber boards may include binders and additives that enhance specific properties such as flexibility, strength, and moisture resistance. These additional components are carefully selected to ensure that the boards meet the stringent requirements of various industries. The manufacturing process involves the careful blending of these materials to create a homogeneous mixture that is then formed into boards of varying thicknesses and densities. This process is critical in ensuring that the final product meets the desired specifications and performance standards. The use of bio-soluble fiber boards is particularly advantageous in industries where traditional insulation materials pose health risks due to fiber inhalation. The bio-soluble nature of these boards means that they dissolve in biological fluids, reducing the risk of respiratory issues for workers handling the material. This makes them a preferred choice in industries with strict health and safety regulations. Furthermore, the environmental benefits of using bio-soluble fiber boards cannot be overstated. As industries and consumers become more conscious of their environmental impact, the demand for sustainable materials is on the rise. Bio-soluble fiber boards offer a solution that aligns with these values, providing effective insulation while minimizing environmental harm. The market for these boards is expected to grow as more industries recognize the benefits of using materials that are both safe and sustainable. Manufacturers are continually innovating to improve the performance and versatility of bio-soluble fiber boards, ensuring that they remain a competitive option in the insulation materials market. As the global focus on sustainability and safety intensifies, the role of bio-soluble fiber boards in various industries is likely to become even more significant.

Petrochemical Furnace, Ceramic Kiln, Others in the Global Bio-Soluble Fiber Board Market:

The Global Bio-Soluble Fiber Board Market finds extensive usage in various high-temperature applications, including petrochemical furnaces, ceramic kilns, and other industrial settings. In petrochemical furnaces, these boards are used for their excellent thermal insulation properties, which help in maintaining the required temperature levels while minimizing heat loss. The boards' ability to withstand extreme temperatures without degrading makes them ideal for use in such demanding environments. Additionally, their bio-soluble nature ensures that they do not pose health risks to workers, making them a safer alternative to traditional insulation materials. In ceramic kilns, bio-soluble fiber boards are used to line the interiors, providing the necessary insulation to maintain consistent temperatures during the firing process. The boards' resistance to thermal shock and chemical reactions ensures that they can withstand the harsh conditions within the kiln, contributing to the production of high-quality ceramic products. The use of these boards in ceramic kilns also helps in reducing energy consumption, as they effectively retain heat, leading to more efficient firing cycles. Beyond petrochemical furnaces and ceramic kilns, bio-soluble fiber boards are used in a variety of other industrial applications where high-temperature insulation is required. These include metallurgy, glass manufacturing, and power generation, among others. In each of these applications, the boards provide the necessary thermal insulation while ensuring safety and environmental compliance. The versatility of bio-soluble fiber boards makes them suitable for use in a wide range of settings, from large industrial facilities to smaller, specialized operations. Their ability to be customized in terms of thickness and density allows them to meet the specific requirements of different applications, ensuring optimal performance. As industries continue to prioritize safety and sustainability, the demand for bio-soluble fiber boards is expected to grow. Their use in high-temperature applications not only enhances operational efficiency but also aligns with the global push towards more sustainable and environmentally friendly practices. The boards' unique combination of properties, including thermal insulation, safety, and environmental benefits, positions them as a valuable solution for industries looking to improve their insulation systems. As more industries recognize the advantages of using bio-soluble fiber boards, their adoption is likely to increase, driving further innovation and development in this market.

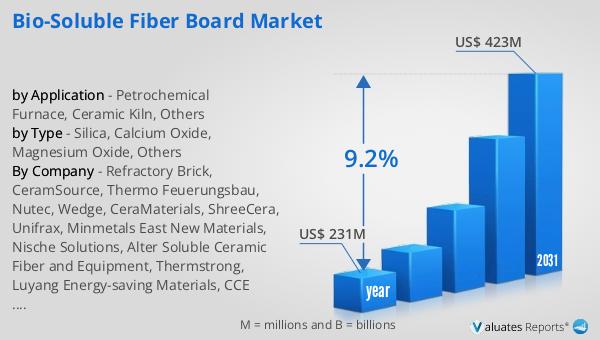

Global Bio-Soluble Fiber Board Market Outlook:

The global market for Bio-Soluble Fiber Board was valued at $231 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $423 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 9.2% over the forecast period. The increasing demand for sustainable and safe insulation materials is a key driver of this market expansion. As industries become more aware of the health and environmental benefits of bio-soluble fiber boards, their adoption is expected to rise. The boards' ability to provide effective thermal insulation while minimizing health risks associated with fiber inhalation makes them an attractive option for various applications. Additionally, the growing focus on reducing carbon footprints and enhancing safety standards is likely to further propel the market's growth. Manufacturers are investing in research and development to improve the performance and versatility of bio-soluble fiber boards, ensuring that they remain competitive in the insulation materials market. As the global focus on sustainability and safety intensifies, the role of bio-soluble fiber boards in various industries is expected to become even more significant. This market outlook highlights the potential for growth and innovation in the bio-soluble fiber board market, offering new opportunities for manufacturers and suppliers.

| Report Metric | Details |

| Report Name | Bio-Soluble Fiber Board Market |

| Accounted market size in year | US$ 231 million |

| Forecasted market size in 2031 | US$ 423 million |

| CAGR | 9.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Refractory Brick, CeramSource, Thermo Feuerungsbau, Nutec, Wedge, CeraMaterials, ShreeCera, Unifrax, Minmetals East New Materials, Nische Solutions, Alter Soluble Ceramic Fiber and Equipment, Thermstrong, Luyang Energy-saving Materials, CCE WOOL, Super Refractory Ceramic Fiber |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |