What is Global Cold Chamber Die Casting Machinery Market?

The Global Cold Chamber Die Casting Machinery Market is a specialized segment within the broader manufacturing equipment industry, focusing on machinery used for die casting processes. Die casting is a metal casting process that involves forcing molten metal under high pressure into a mold cavity. Cold chamber die casting machines are specifically designed for metals with high melting points, such as aluminum, magnesium, and copper. These machines are essential in producing complex and precise metal components with excellent surface finishes and dimensional accuracy. The market for these machines is driven by the increasing demand for lightweight, durable, and high-performance metal parts across various industries, including automotive, aerospace, electronics, and consumer goods. As industries continue to seek efficient and cost-effective manufacturing solutions, the demand for advanced cold chamber die casting machinery is expected to grow. This market is characterized by technological advancements, such as automation and digitalization, which enhance the efficiency and precision of the casting process. Additionally, the market is influenced by factors such as raw material prices, energy costs, and environmental regulations, which impact the overall production costs and operational efficiency of die casting operations.

Less Than 4 000 kN, Between 4 000 kN and 10 000 kN, More Than 10 000 kN in the Global Cold Chamber Die Casting Machinery Market:

In the Global Cold Chamber Die Casting Machinery Market, machines are categorized based on their clamping force, measured in kilonewtons (kN). The first category, machines with less than 4,000 kN, is typically used for smaller components and applications where high precision is required but the size and weight of the parts are relatively low. These machines are ideal for producing intricate parts with complex geometries, often used in industries such as electronics and small appliances. Their compact size and lower operational costs make them suitable for small to medium-sized enterprises that require flexibility and efficiency in their production processes. The second category, machines with a clamping force between 4,000 kN and 10,000 kN, represents a significant portion of the market. These machines are versatile and can handle a wide range of applications, making them popular in the automotive industry, where they are used to produce medium-sized components such as engine blocks, transmission cases, and structural parts. The balance between size, power, and cost makes this category attractive to manufacturers looking to optimize their production capabilities while maintaining high-quality standards. The third category, machines with more than 10,000 kN, is designed for large-scale production of heavy and complex components. These machines are essential for industries that require robust and durable parts, such as aerospace and heavy machinery. The high clamping force allows for the production of large components with excellent structural integrity and minimal defects. However, these machines require significant investment and operational expertise, making them more suitable for large enterprises with substantial production volumes and resources. Across all categories, the market is witnessing a trend towards automation and digitalization, with manufacturers integrating advanced technologies such as IoT, AI, and machine learning to enhance the efficiency, precision, and sustainability of the die casting process. This technological evolution is driven by the need to reduce production costs, improve product quality, and meet stringent environmental regulations. As a result, manufacturers are increasingly adopting smart manufacturing solutions that enable real-time monitoring, predictive maintenance, and data-driven decision-making, ultimately enhancing the competitiveness and profitability of their operations.

Automobile, Household Appliances, 3C, Others in the Global Cold Chamber Die Casting Machinery Market:

The Global Cold Chamber Die Casting Machinery Market finds extensive applications across various industries, with significant usage in the automobile sector. In the automotive industry, these machines are crucial for producing lightweight and high-strength components such as engine blocks, transmission cases, and structural parts. The demand for fuel-efficient and environmentally friendly vehicles drives the need for lightweight materials, making die casting an essential process in automotive manufacturing. The precision and efficiency of cold chamber die casting machines enable manufacturers to produce complex and high-quality components that meet the stringent standards of the automotive industry. In the household appliances sector, cold chamber die casting machines are used to manufacture components for products such as washing machines, refrigerators, and air conditioners. The ability to produce intricate and durable parts with excellent surface finishes makes these machines ideal for the production of high-quality household appliances. As consumers increasingly demand energy-efficient and aesthetically pleasing products, manufacturers rely on advanced die casting technologies to meet these expectations. The 3C industry, which includes computers, communications, and consumer electronics, also benefits from the capabilities of cold chamber die casting machines. These machines are used to produce components for smartphones, laptops, and other electronic devices, where precision and miniaturization are critical. The growing demand for compact and high-performance electronic devices drives the need for advanced die casting solutions that can deliver the required quality and precision. Additionally, the market finds applications in other industries such as aerospace, medical devices, and industrial machinery, where the production of complex and high-performance metal components is essential. In these sectors, the ability to produce lightweight, durable, and high-precision parts is crucial for meeting the demanding requirements of modern manufacturing. Overall, the versatility and efficiency of cold chamber die casting machines make them indispensable across a wide range of industries, driving their adoption and growth in the global market.

Global Cold Chamber Die Casting Machinery Market Outlook:

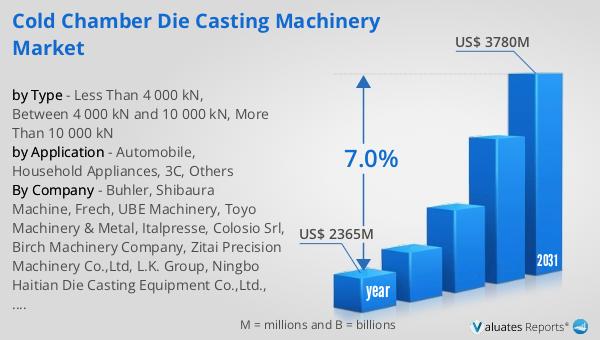

The global market for Cold Chamber Die Casting Machinery was valued at $2,365 million in 2024 and is anticipated to expand to a revised size of $3,780 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.0% over the forecast period. The L.K. Group stands out as the leading company in this market, commanding 15% of the total market share, while other companies hold less than 10% each. Geographically, China dominates the market, accounting for nearly 60% of the global share, followed by Europe with 20% and Japan with approximately 10%. In terms of machine types, those with a clamping force between 4,000 kN and 10,000 kN hold a significant share of about 50%. The automobile industry is the primary application sector, representing nearly 70% of the market. This market outlook highlights the robust growth potential and competitive landscape of the global cold chamber die casting machinery market, driven by technological advancements and increasing demand across various industries. The dominance of key players and regions underscores the strategic importance of innovation and market penetration in maintaining a competitive edge in this dynamic industry.

| Report Metric | Details |

| Report Name | Cold Chamber Die Casting Machinery Market |

| Accounted market size in year | US$ 2365 million |

| Forecasted market size in 2031 | US$ 3780 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Buhler, Shibaura Machine, Frech, UBE Machinery, Toyo Machinery & Metal, Italpresse, Colosio Srl, Birch Machinery Company, Zitai Precision Machinery Co.,Ltd, L.K. Group, Ningbo Haitian Die Casting Equipment Co.,Ltd., Yizumi Group, Guannan Die Casting Machine, Suzhou Sanji, Wuxi Xinjiasheng, Ningbo Dongfang |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |