What is Global Programmable Microchip Market?

The Global Programmable Microchip Market is a dynamic and rapidly evolving sector within the broader semiconductor industry. Programmable microchips, often referred to as microcontrollers or microprocessors, are integral components in a wide array of electronic devices. These chips are designed to perform specific tasks and can be programmed to execute a variety of functions, making them highly versatile. The market for these microchips is driven by the increasing demand for smart and connected devices across various industries, including consumer electronics, automotive, aerospace, medical, and telecommunications. As technology advances, the need for more sophisticated and efficient microchips grows, leading to continuous innovation and development in this field. The global market is characterized by intense competition among key players who are constantly striving to enhance their product offerings and expand their market presence. This competitive landscape fosters innovation, resulting in the development of microchips with improved performance, lower power consumption, and enhanced security features. Overall, the Global Programmable Microchip Market plays a crucial role in the advancement of technology and the proliferation of smart devices, making it a vital component of the modern digital economy.

Fabless, Integrated Device, Others in the Global Programmable Microchip Market:

In the Global Programmable Microchip Market, there are several key business models and categories that companies operate within, including fabless, integrated device manufacturers (IDMs), and others. Fabless companies are those that design and sell hardware devices and semiconductor chips but outsource the fabrication of the devices to specialized manufacturers known as foundries. This model allows fabless companies to focus on research and development, design, and marketing, while leveraging the manufacturing expertise and economies of scale of foundries. This approach is particularly advantageous for companies that want to minimize capital expenditure and operational complexities associated with owning and operating semiconductor fabrication facilities. On the other hand, Integrated Device Manufacturers (IDMs) are companies that design, manufacture, and sell their own semiconductor products. IDMs have the advantage of controlling the entire production process, from design to manufacturing, which can lead to better quality control, faster time-to-market, and the ability to innovate more rapidly. However, this model requires significant investment in manufacturing facilities and technology, which can be a barrier to entry for smaller companies. In addition to fabless and IDMs, there are other players in the market, such as foundries and design houses, that provide specialized services and play a crucial role in the semiconductor supply chain. Foundries are companies that focus solely on manufacturing semiconductor devices for other companies, while design houses specialize in the design and development of semiconductor products. These various business models and categories within the Global Programmable Microchip Market contribute to a diverse and competitive landscape, driving innovation and growth in the industry.

Consumer Electronics, Aerospace, Automotive, Medical, Telecom in the Global Programmable Microchip Market:

The Global Programmable Microchip Market finds extensive applications across various sectors, including consumer electronics, aerospace, automotive, medical, and telecommunications. In consumer electronics, programmable microchips are essential components in devices such as smartphones, tablets, laptops, and smart home appliances. They enable these devices to perform complex tasks, process data efficiently, and connect to other devices, enhancing user experience and functionality. In the aerospace industry, programmable microchips are used in avionics systems, navigation, and communication equipment, where reliability and precision are critical. These chips help in managing complex systems and ensuring the safety and efficiency of aircraft operations. In the automotive sector, programmable microchips are integral to the development of advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) technologies. They enable real-time data processing and communication between various vehicle systems, improving safety, performance, and user experience. In the medical field, programmable microchips are used in diagnostic equipment, patient monitoring systems, and medical devices, where they help in accurate data collection, processing, and analysis, leading to better patient outcomes. In telecommunications, programmable microchips are crucial for the development of network infrastructure, enabling faster data transmission, improved connectivity, and the deployment of next-generation technologies such as 5G. Overall, the versatility and functionality of programmable microchips make them indispensable in these industries, driving innovation and enhancing the capabilities of modern technology.

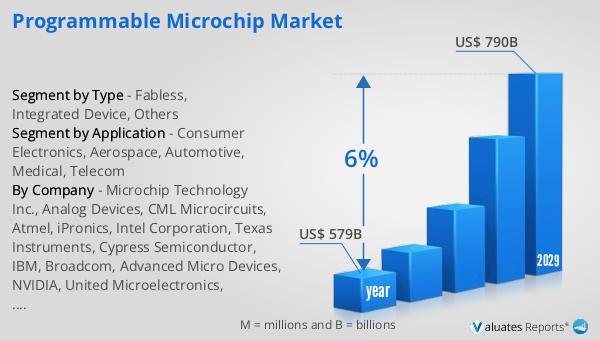

Global Programmable Microchip Market Outlook:

The global semiconductor market, which includes the Global Programmable Microchip Market, was valued at approximately $579 billion in 2022. This market is anticipated to grow significantly, reaching around $790 billion by 2029, with a compound annual growth rate (CAGR) of 6% during the forecast period. This growth is driven by the increasing demand for advanced semiconductor technologies across various industries, including consumer electronics, automotive, aerospace, medical, and telecommunications. The proliferation of smart devices, the rise of the Internet of Things (IoT), and the deployment of 5G networks are some of the key factors contributing to this growth. Additionally, the ongoing advancements in semiconductor manufacturing processes and the development of new materials and technologies are expected to further fuel the expansion of the market. As the demand for more powerful, efficient, and secure microchips continues to rise, companies in the semiconductor industry are investing heavily in research and development to stay competitive and meet the evolving needs of their customers. This dynamic and rapidly changing market presents numerous opportunities for innovation and growth, making it an exciting and vital component of the global technology landscape.

| Report Metric | Details |

| Report Name | Programmable Microchip Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2025 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Microchip Technology Inc., Analog Devices, CML Microcircuits, Atmel, iPronics, Intel Corporation, Texas Instruments, Cypress Semiconductor, IBM, Broadcom, Advanced Micro Devices, NVIDIA, United Microelectronics, STMicroelectronics, Taiwan Semiconductor Manufacturing Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |