What is Global Electropermanent Lifting Magnets (EPMM) Market?

The Global Electropermanent Lifting Magnets (EPMM) Market is an intriguing segment within the industrial lifting equipment industry. Electropermanent lifting magnets are specialized devices used to lift and transport heavy ferrous materials without the need for a continuous power supply. These magnets combine the benefits of both permanent and electromagnets, offering a reliable and energy-efficient solution for material handling. They are particularly valued for their ability to maintain a magnetic hold even during power outages, ensuring safety and efficiency in various industrial applications. The market for EPMMs is driven by the increasing demand for efficient and safe lifting solutions in industries such as manufacturing, construction, and logistics. As industries continue to automate and seek more efficient ways to handle materials, the demand for EPMMs is expected to grow. These magnets are available in various sizes and capacities, catering to different industrial needs, from small-scale operations to large manufacturing plants. The versatility and reliability of EPMMs make them a preferred choice for businesses looking to enhance their operational efficiency and safety standards. As technology advances, the market is likely to see further innovations, making these magnets even more integral to modern industrial processes.

Below 500 Kg, 500-1000 Kg, Above 1000 Kg in the Global Electropermanent Lifting Magnets (EPMM) Market:

In the Global Electropermanent Lifting Magnets (EPMM) Market, the categorization based on lifting capacity is crucial for meeting diverse industrial needs. The segment for magnets with a capacity below 500 Kg is particularly significant for industries that require precision and flexibility in handling smaller loads. These magnets are often used in workshops, small manufacturing units, and in applications where delicate handling of materials is essential. Their compact size and ease of use make them ideal for operations that demand frequent lifting and moving of lighter materials. On the other hand, the 500-1000 Kg category serves a broader range of applications, providing a balance between capacity and versatility. This segment is popular in medium-sized manufacturing facilities and warehouses where the handling of moderately heavy materials is routine. These magnets offer a good compromise between power and efficiency, making them suitable for a variety of tasks without the need for excessive energy consumption. The above 1000 Kg category represents the heavy-duty end of the market, catering to industries that deal with large and heavy materials. These powerful magnets are essential in sectors like steel production, shipbuilding, and large-scale construction projects, where the lifting and transportation of massive loads are commonplace. The ability to handle such heavy materials safely and efficiently is a key factor driving the demand for these high-capacity magnets. Each of these categories plays a vital role in the overall EPMM market, addressing specific needs and challenges faced by different industries. The choice of magnet capacity is often dictated by the nature of the materials being handled, the frequency of use, and the specific requirements of the operation. As industries continue to evolve and expand, the demand for tailored lifting solutions is expected to grow, further diversifying the market for electropermanent lifting magnets. The ongoing advancements in magnet technology, coupled with the increasing emphasis on safety and efficiency, are likely to drive innovation and growth across all segments of the EPMM market. This dynamic landscape presents numerous opportunities for manufacturers and suppliers to develop and offer products that meet the changing needs of their customers, ensuring that electropermanent lifting magnets remain a critical component of modern industrial operations.

Steel and Metal Fabrication, Automotive and Aerospace, Manufacturing and Warehousing, Others in the Global Electropermanent Lifting Magnets (EPMM) Market:

The usage of Global Electropermanent Lifting Magnets (EPMM) Market spans across various industries, each benefiting from the unique advantages these magnets offer. In the steel and metal fabrication industry, EPMMs are indispensable tools for handling heavy metal sheets, plates, and components. Their ability to securely lift and transport ferrous materials without the need for continuous power makes them ideal for environments where safety and efficiency are paramount. These magnets help streamline operations, reduce manual labor, and minimize the risk of accidents, making them a valuable asset in metal fabrication processes. In the automotive and aerospace sectors, EPMMs play a crucial role in the assembly and manufacturing processes. The precision and reliability of these magnets ensure that components are handled with care, reducing the risk of damage and ensuring high-quality standards. The ability to lift and position heavy parts with ease enhances productivity and supports the complex assembly operations typical of these industries. In manufacturing and warehousing, EPMMs contribute to efficient material handling and inventory management. Their versatility allows them to be used in various applications, from moving raw materials to handling finished products. The energy efficiency and safety features of EPMMs make them an attractive option for businesses looking to optimize their operations and reduce operational costs. Other industries, such as construction, shipbuilding, and logistics, also benefit from the use of EPMMs. In construction, these magnets are used to lift and position steel beams and other heavy materials, facilitating the building process. In shipbuilding, they assist in the assembly of large metal structures, ensuring precision and safety. The logistics industry relies on EPMMs for efficient loading and unloading of cargo, improving turnaround times and reducing labor costs. Overall, the versatility and reliability of electropermanent lifting magnets make them a valuable tool across a wide range of industries. Their ability to enhance safety, efficiency, and productivity ensures their continued relevance in modern industrial operations.

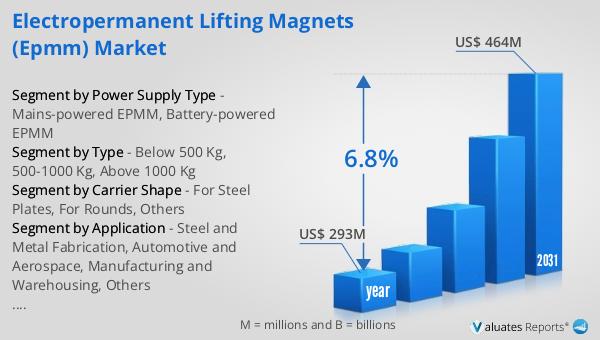

Global Electropermanent Lifting Magnets (EPMM) Market Outlook:

The global market for Electropermanent Lifting Magnets (EPMM) was valued at approximately $293 million in 2024, reflecting its significant role in various industrial sectors. This market is projected to grow substantially, reaching an estimated size of $464 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. The increasing demand for efficient and safe material handling solutions is a key driver of this market expansion. Industries are continually seeking ways to enhance operational efficiency and safety, and EPMMs offer a reliable solution. Their ability to maintain a magnetic hold without continuous power supply makes them particularly appealing in environments where power stability is a concern. As industries such as manufacturing, construction, and logistics continue to grow and evolve, the demand for advanced lifting solutions like EPMMs is expected to rise. The market's growth is also supported by technological advancements that enhance the performance and capabilities of these magnets. As a result, manufacturers and suppliers are likely to invest in research and development to meet the changing needs of their customers. This dynamic market presents numerous opportunities for innovation and growth, ensuring that electropermanent lifting magnets remain a critical component of modern industrial operations.

| Report Metric | Details |

| Report Name | Electropermanent Lifting Magnets (EPMM) Market |

| Accounted market size in year | US$ 293 million |

| Forecasted market size in 2031 | US$ 464 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Power Supply Type |

|

| Segment by Internal Structure |

|

| Segment by Carrier Shape |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hishiko, Tecnomagnete, Walker Magnetics, KANETEC, Magnetool, Inc., Sarda Magnets Group, Armstrong Magnetics, Walmag Magnetics, Braillon Magnetics, Airpes, Eriez Manufacturing, Uptech Engineering, Vega Technik, Assfalg GmbH, Flaig Magnetsysteme, SGM Magnetics, DIMET, Earth-Chain Enterprise, HVR Magnetic, HuaiGe Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |