What is Global Refrigerator Vacuum Insulation Panel Market?

The Global Refrigerator Vacuum Insulation Panel Market is a specialized segment within the broader insulation industry, focusing on the production and application of vacuum insulation panels (VIPs) specifically designed for refrigerators. These panels are highly efficient insulators, providing superior thermal resistance compared to traditional insulation materials. VIPs are composed of a core material encased in a vacuum-sealed barrier, which significantly reduces heat transfer. This technology is crucial for enhancing the energy efficiency of refrigerators, as it minimizes the amount of energy required to maintain the desired internal temperature. The market for these panels is driven by the increasing demand for energy-efficient appliances, as consumers and manufacturers alike seek to reduce energy consumption and carbon footprints. Additionally, regulatory standards and incentives promoting energy efficiency further bolster the market's growth. The adoption of VIPs in refrigerators not only contributes to energy savings but also allows for more storage space within the same appliance footprint, as the panels are thinner than conventional insulation. This dual benefit of energy efficiency and space optimization makes VIPs an attractive choice for refrigerator manufacturers, thereby driving the market's expansion.

Fumed Silica Type, Glass Fiber Type, Others in the Global Refrigerator Vacuum Insulation Panel Market:

In the Global Refrigerator Vacuum Insulation Panel Market, different types of core materials are used to construct these panels, each offering unique properties and benefits. Fumed silica is one of the most commonly used materials in VIPs. It is a highly porous and lightweight material that provides excellent thermal insulation properties. The fine particles of fumed silica create a structure that traps air, significantly reducing heat transfer. This makes fumed silica-based VIPs highly effective in maintaining low temperatures within refrigerators, thereby enhancing energy efficiency. Additionally, fumed silica is known for its durability and long lifespan, making it a reliable choice for manufacturers aiming for long-term performance. Glass fiber is another material used in the construction of vacuum insulation panels. Glass fiber-based VIPs are known for their robustness and resistance to mechanical stress. The fibrous structure of glass fiber provides a strong framework that supports the vacuum-sealed barrier, ensuring the panel's integrity over time. While glass fiber VIPs may not offer the same level of thermal resistance as fumed silica, they are often chosen for applications where durability and structural strength are prioritized. This makes them suitable for use in environments where the panels may be subject to physical impact or pressure. Apart from fumed silica and glass fiber, there are other materials used in the production of VIPs, each catering to specific needs and applications. These may include materials like polyurethane foam or polystyrene, which offer varying degrees of insulation efficiency and cost-effectiveness. Manufacturers may opt for these alternative materials based on factors such as production costs, desired insulation performance, and specific application requirements. The choice of material can also be influenced by environmental considerations, as some materials may offer better sustainability profiles than others. The diversity in core materials allows manufacturers to tailor VIPs to meet the specific needs of different refrigerator models and applications. For instance, high-end refrigerators may prioritize maximum energy efficiency and opt for fumed silica VIPs, while more budget-friendly models may balance cost and performance by using alternative materials. This flexibility in material choice is a key factor driving the adoption of VIPs across a wide range of refrigerator products, from household appliances to commercial refrigeration units. Overall, the variety of materials used in the Global Refrigerator Vacuum Insulation Panel Market reflects the industry's commitment to innovation and adaptability. By offering a range of options, manufacturers can address the diverse needs of consumers and businesses, ensuring that VIPs remain a vital component in the quest for energy-efficient refrigeration solutions. As the market continues to evolve, the development of new materials and technologies will likely further enhance the performance and appeal of vacuum insulation panels, solidifying their role in the future of refrigeration.

Home Appliances, Cold Chain Transport Vehicles, Medical Equipment, Others in the Global Refrigerator Vacuum Insulation Panel Market:

The Global Refrigerator Vacuum Insulation Panel Market finds its applications across various sectors, each benefiting from the unique properties of VIPs. In the realm of home appliances, VIPs are primarily used in refrigerators and freezers. The superior insulation provided by these panels allows for significant energy savings, as they reduce the amount of energy required to maintain the desired temperature. This not only lowers electricity bills for consumers but also contributes to environmental sustainability by reducing the carbon footprint of household appliances. Additionally, the thin profile of VIPs enables manufacturers to design refrigerators with more internal storage space without increasing the overall size of the appliance, offering consumers greater convenience and flexibility. In cold chain transport vehicles, VIPs play a crucial role in maintaining the integrity of temperature-sensitive goods during transit. These vehicles, which include refrigerated trucks and containers, rely on efficient insulation to preserve the quality and safety of perishable products such as food and pharmaceuticals. By minimizing heat transfer, VIPs help maintain a stable internal temperature, ensuring that goods remain fresh and effective throughout the transportation process. This is particularly important in the pharmaceutical industry, where temperature fluctuations can compromise the efficacy of vaccines and other medical products. The use of VIPs in cold chain logistics not only enhances product safety but also reduces energy consumption, contributing to more sustainable transport solutions. In the medical equipment sector, VIPs are used in devices and storage units that require precise temperature control. For instance, medical refrigerators and freezers that store sensitive biological samples or medications benefit from the enhanced insulation provided by VIPs. These panels help maintain consistent temperatures, preventing fluctuations that could damage or degrade the stored materials. The reliability and efficiency of VIPs make them an ideal choice for medical applications, where maintaining the integrity of stored items is of utmost importance. Beyond these specific areas, VIPs are also utilized in other applications where superior insulation is required. This may include industrial refrigeration systems, scientific research facilities, and even some consumer electronics that require temperature regulation. The versatility of VIPs allows them to be adapted for a wide range of uses, making them a valuable component in various industries. Overall, the application of vacuum insulation panels in these areas highlights their importance in enhancing energy efficiency, product safety, and environmental sustainability. As industries continue to prioritize these factors, the demand for VIPs is likely to grow, driving further innovation and development in the Global Refrigerator Vacuum Insulation Panel Market. By providing effective insulation solutions across diverse sectors, VIPs contribute to a more energy-efficient and sustainable future.

Global Refrigerator Vacuum Insulation Panel Market Outlook:

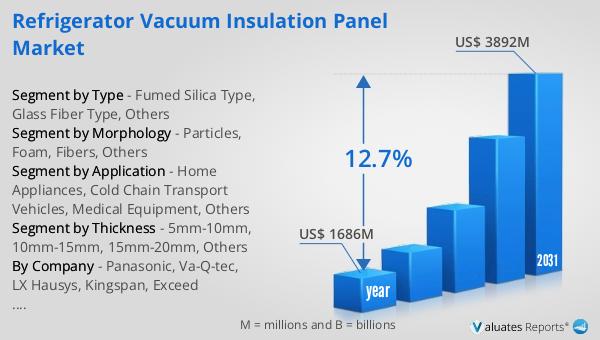

The outlook for the Global Refrigerator Vacuum Insulation Panel Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 1,686 million. Looking ahead, it is anticipated to expand significantly, reaching an estimated size of US$ 3,892 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 12.7% over the forecast period. This robust expansion can be attributed to several factors, including the increasing demand for energy-efficient appliances and the growing awareness of environmental sustainability. As consumers and manufacturers alike seek to reduce energy consumption and carbon footprints, the adoption of vacuum insulation panels in refrigerators is likely to rise. These panels offer superior thermal resistance, which enhances the energy efficiency of refrigerators and contributes to lower electricity bills for consumers. Additionally, regulatory standards and incentives promoting energy efficiency further support the market's growth. The ability of VIPs to provide both energy savings and space optimization makes them an attractive choice for refrigerator manufacturers, driving the market's expansion. As the market continues to evolve, the development of new materials and technologies will likely further enhance the performance and appeal of vacuum insulation panels, solidifying their role in the future of refrigeration.

| Report Metric | Details |

| Report Name | Refrigerator Vacuum Insulation Panel Market |

| Accounted market size in year | US$ 1686 million |

| Forecasted market size in 2031 | US$ 3892 million |

| CAGR | 12.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Morphology |

|

| Segment by Thickness |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Panasonic, Va-Q-tec, LX Hausys, Kingspan, Exceed Technologies, Porextherm, Sealed Air, Turna, Knauf Insulation, OCI Company, Turvac Vacuum Insulation, Tapered Plus, Super Tech Advanced Material, Micolon, Zaisheng Technology, Sanyou Dior, Peak-Tech New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |