What is Screw & band Hose Clamps - Global Market?

Screw and band hose clamps are essential components in various industries, designed to secure hoses over fittings, preventing leaks and ensuring a tight seal. These clamps are typically made from durable materials like stainless steel or carbon steel, providing the necessary strength and resistance to corrosion. The global market for screw and band hose clamps is driven by their widespread application in sectors such as automotive, industrial, and water treatment. These clamps are crucial for maintaining the integrity of fluid systems, ensuring that hoses remain securely attached under varying pressure conditions. The market is characterized by a diverse range of products, catering to different sizes and specifications to meet the specific needs of various applications. As industries continue to expand and modernize, the demand for reliable and efficient hose clamps is expected to grow, highlighting their importance in maintaining operational efficiency and safety. The global market for these clamps is not only vast but also competitive, with numerous manufacturers striving to innovate and improve their offerings to meet the evolving demands of their customers.

Carbon Steel, Stainless Steel, Others in the Screw & band Hose Clamps - Global Market:

When it comes to the materials used in screw and band hose clamps, carbon steel and stainless steel are the most prevalent, each offering distinct advantages. Carbon steel is known for its strength and durability, making it a popular choice for applications where high tensile strength is required. It is often used in environments where the clamp will not be exposed to corrosive elements, as carbon steel can be prone to rust if not properly coated or treated. On the other hand, stainless steel is highly resistant to corrosion, making it ideal for use in harsh environments where exposure to moisture or chemicals is a concern. This material is particularly favored in the automotive and industrial sectors, where reliability and longevity are paramount. Stainless steel clamps are also preferred in the water treatment industry, where they must withstand constant exposure to water and other potentially corrosive substances. In addition to these two primary materials, there are other options available, such as plastic or composite materials, which are used in specific applications where metal clamps may not be suitable. These alternative materials can offer benefits such as reduced weight or cost, but they may not provide the same level of strength or durability as metal clamps. The choice of material for a hose clamp is often dictated by the specific requirements of the application, including factors such as the operating environment, pressure levels, and the type of fluid being transported. As the global market for screw and band hose clamps continues to evolve, manufacturers are constantly exploring new materials and technologies to enhance the performance and versatility of their products. This ongoing innovation is crucial for meeting the diverse needs of industries that rely on these clamps to ensure the safe and efficient operation of their systems.

Automotive, Industrial, Water Treatment, Others in the Screw & band Hose Clamps - Global Market:

Screw and band hose clamps are utilized across a wide range of industries, each with its own specific requirements and challenges. In the automotive industry, these clamps are essential for securing hoses in various systems, including cooling, fuel, and air intake systems. They ensure that hoses remain securely attached, preventing leaks that could lead to engine damage or reduced performance. The reliability of hose clamps in the automotive sector is critical, as any failure could result in costly repairs or even safety hazards. In industrial applications, hose clamps are used to secure hoses in machinery and equipment, where they must withstand high pressures and temperatures. These clamps play a vital role in maintaining the efficiency and safety of industrial operations, ensuring that fluids are transported without leaks or interruptions. In the water treatment industry, hose clamps are used to secure hoses in systems that transport water and other fluids. They must be resistant to corrosion and able to withstand constant exposure to moisture, making stainless steel a popular choice for this application. In addition to these primary industries, screw and band hose clamps are also used in a variety of other sectors, including agriculture, construction, and marine. Each of these industries has its own unique requirements, and manufacturers must be able to provide clamps that meet the specific needs of their customers. The versatility and reliability of screw and band hose clamps make them an indispensable component in many applications, ensuring that systems operate smoothly and efficiently. As industries continue to evolve and face new challenges, the demand for high-quality hose clamps is expected to grow, driving innovation and development in the global market.

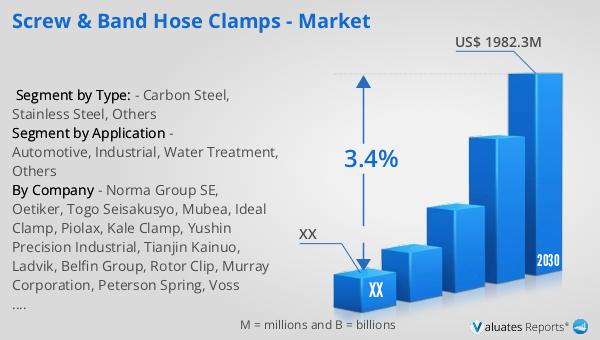

Screw & band Hose Clamps - Global Market Outlook:

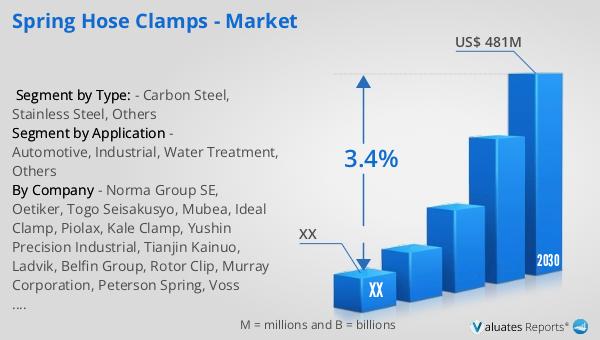

The global market for screw and band hose clamps was valued at approximately $1,573.8 million in 2023, with projections indicating a growth to around $1,982.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. In North America, the market for these clamps was valued at a certain amount in 2023, with expectations of reaching a higher value by 2030, although specific figures are not provided. The steady growth in this market can be attributed to the increasing demand for reliable and efficient hose clamps across various industries, including automotive, industrial, and water treatment. As these industries continue to expand and modernize, the need for high-quality hose clamps is expected to rise, driving market growth. Manufacturers are focusing on innovation and the development of new materials and technologies to meet the evolving demands of their customers, ensuring that they remain competitive in this dynamic market. The global market for screw and band hose clamps is characterized by a diverse range of products, catering to different sizes and specifications to meet the specific needs of various applications. As industries continue to expand and modernize, the demand for reliable and efficient hose clamps is expected to grow, highlighting their importance in maintaining operational efficiency and safety.

| Report Metric | Details |

| Report Name | Screw & band Hose Clamps - Market |

| Forecasted market size in 2030 | US$ 1982.3 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Norma Group SE, Oetiker, Togo Seisakusyo, Mubea, Ideal Clamp, Piolax, Kale Clamp, Yushin Precision Industrial, Tianjin Kainuo, Ladvik, Belfin Group, Rotor Clip, Murray Corporation, Peterson Spring, Voss Industries, BAND-IT, Toyox, Gates, Topy Fasteners, JCS Hi-Torque, PT Coupling, Dongguan Haitong, Mikalor, Tianjin Aojin, Hengwei Check Hoop, Xinyu Fastener, Tianjin Nuocheng, Cangzhou Zhongxin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |