What is Low Pressure Polyurethane Foaming Machine - Global Market?

Low Pressure Polyurethane Foaming Machines are specialized equipment used in the production of polyurethane foam, a versatile material known for its insulating and cushioning properties. These machines operate by mixing two liquid components, polyol and isocyanate, under low pressure to create a foam that can be molded into various shapes and densities. The global market for these machines is driven by their widespread application across multiple industries, including automotive, construction, and appliances. The demand for energy-efficient and lightweight materials has spurred the growth of polyurethane foam, thereby increasing the need for efficient foaming machines. These machines are designed to offer precision and control in the foaming process, ensuring consistent quality and reducing material waste. As industries continue to innovate and seek sustainable solutions, the role of low pressure polyurethane foaming machines becomes increasingly significant, making them a crucial component in modern manufacturing processes. The global market for these machines is expected to grow as more industries recognize the benefits of polyurethane foam in enhancing product performance and sustainability.

Small PU Foaming Machine, Large PU Foaming Machine in the Low Pressure Polyurethane Foaming Machine - Global Market:

Small PU Foaming Machines and Large PU Foaming Machines are two categories within the low pressure polyurethane foaming machine market, each catering to different production needs and scales. Small PU Foaming Machines are typically used for applications that require lower volumes of foam production. These machines are ideal for small to medium-sized enterprises or specialized production lines where precision and flexibility are paramount. They are often employed in industries such as automotive for producing parts like seat cushions and headrests, where smaller batches and custom designs are common. The compact size and ease of operation make them suitable for businesses looking to optimize space and reduce operational costs. On the other hand, Large PU Foaming Machines are designed for high-volume production environments. These machines are capable of producing large quantities of foam efficiently, making them suitable for industries with high demand, such as construction and large-scale manufacturing. In the construction industry, for example, large machines are used to produce insulation panels and structural components that require consistent quality and durability. The ability to handle large volumes without compromising on quality makes these machines indispensable for large manufacturers. Both small and large PU foaming machines play a vital role in the global market, offering solutions tailored to the specific needs of different industries. The choice between small and large machines depends on factors such as production volume, space availability, and specific application requirements. As the demand for polyurethane foam continues to rise, manufacturers are increasingly investing in these machines to enhance their production capabilities and meet market demands. The versatility and efficiency of both small and large PU foaming machines ensure that they remain integral to the manufacturing processes across various sectors, contributing to the growth and innovation within the industry.

Automotive, Electrical Appliance, Construction, Others in the Low Pressure Polyurethane Foaming Machine - Global Market:

Low Pressure Polyurethane Foaming Machines find extensive usage across various sectors, including automotive, electrical appliances, construction, and others, due to their ability to produce high-quality foam with excellent properties. In the automotive industry, these machines are used to manufacture components such as seat cushions, armrests, and headliners. The lightweight and durable nature of polyurethane foam make it an ideal material for enhancing vehicle comfort and fuel efficiency. In the electrical appliance sector, low pressure foaming machines are employed to produce insulation for refrigerators, freezers, and water heaters. The superior insulating properties of polyurethane foam help in improving energy efficiency and reducing operational costs for consumers. In the construction industry, these machines are used to create insulation panels, roofing materials, and sealants. The ability of polyurethane foam to provide excellent thermal insulation and moisture resistance makes it a preferred choice for builders and architects aiming to construct energy-efficient and sustainable buildings. Beyond these primary sectors, low pressure polyurethane foaming machines are also utilized in the production of furniture, packaging materials, and footwear. The versatility of polyurethane foam allows manufacturers to explore innovative applications, further driving the demand for these machines. As industries continue to prioritize sustainability and efficiency, the role of low pressure polyurethane foaming machines in delivering high-performance materials becomes increasingly crucial. Their widespread adoption across diverse sectors underscores their importance in modern manufacturing and their contribution to advancing industry standards.

Low Pressure Polyurethane Foaming Machine - Global Market Outlook:

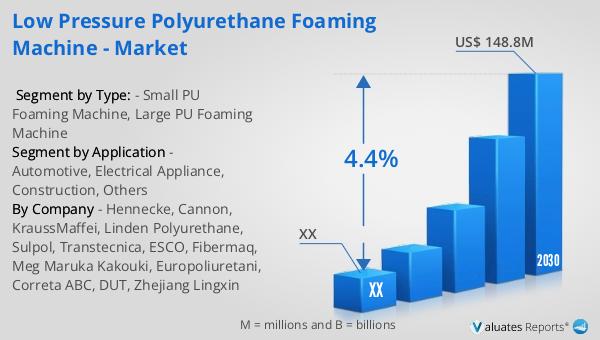

The global market for Low Pressure Polyurethane Foaming Machines was valued at approximately US$ 110.5 million in 2023, with projections indicating a growth to around US$ 148.8 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.4% during the forecast period from 2024 to 2030. The North American segment of this market was also valued at a significant amount in 2023, with expectations of reaching a higher value by 2030, although specific figures for this region were not provided. The steady growth in this market can be attributed to the increasing demand for polyurethane foam across various industries, driven by its superior properties and versatility. As industries continue to seek materials that offer energy efficiency, durability, and sustainability, the demand for low pressure polyurethane foaming machines is likely to rise. This market outlook highlights the potential for growth and innovation within the industry, as manufacturers invest in advanced technologies to meet evolving market needs. The projected increase in market size reflects the expanding applications of polyurethane foam and the critical role of foaming machines in supporting this growth.

| Report Metric | Details |

| Report Name | Low Pressure Polyurethane Foaming Machine - Market |

| Forecasted market size in 2030 | US$ 148.8 million |

| CAGR | 4.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hennecke, Cannon, KraussMaffei, Linden Polyurethane, Sulpol, Transtecnica, ESCO, Fibermaq, Meg Maruka Kakouki, Europoliuretani, Correta ABC, DUT, Zhejiang Lingxin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |