What is Global Heavy-Duty Belt Scales Market?

The Global Heavy-Duty Belt Scales Market is a specialized segment within the industrial equipment sector, focusing on devices that measure the flow rate of materials on conveyor belts. These scales are crucial for industries that handle bulk materials, as they provide accurate and real-time data on the quantity of material being transported. This information is vital for process optimization, inventory management, and ensuring compliance with production standards. Heavy-duty belt scales are designed to withstand harsh industrial environments, offering durability and precision. They are used in various sectors, including mining, cement, power generation, and metallurgy, where large volumes of materials need to be measured efficiently. The market for these scales is driven by the increasing demand for automation and efficiency in industrial processes, as well as the need for accurate measurement systems to reduce waste and improve productivity. Technological advancements have led to the development of more sophisticated belt scales that offer enhanced accuracy and reliability, further fueling market growth. As industries continue to expand and modernize, the demand for heavy-duty belt scales is expected to rise, making it a critical component of industrial operations worldwide.

Single Roller Scale, Multi-Roller Scale in the Global Heavy-Duty Belt Scales Market:

In the Global Heavy-Duty Belt Scales Market, two primary types of scales are prevalent: Single Roller Scales and Multi-Roller Scales. Single Roller Scales are designed with simplicity and cost-effectiveness in mind. They consist of a single roller that supports the conveyor belt, measuring the weight of the material passing over it. These scales are ideal for applications where precision is not the highest priority but where a general measurement is sufficient. They are often used in industries where the material flow is relatively consistent and where the cost of equipment is a significant consideration. The simplicity of Single Roller Scales makes them easy to install and maintain, which is a significant advantage for operations with limited technical resources. On the other hand, Multi-Roller Scales offer a higher level of accuracy and are suitable for applications where precise measurement is critical. These scales use multiple rollers to support the conveyor belt, providing a more stable platform for measurement. The use of multiple rollers helps to average out any inconsistencies in the belt or material flow, resulting in more accurate readings. Multi-Roller Scales are often used in industries where the material being transported is of high value or where precise measurement is necessary for quality control. They are more complex and typically more expensive than Single Roller Scales, but the investment is justified by the increased accuracy and reliability they provide. In the mining industry, for example, Multi-Roller Scales are essential for ensuring that the correct amount of material is extracted and processed, which directly impacts profitability. Similarly, in the cement and building materials sector, accurate measurement of raw materials is crucial for maintaining product quality and consistency. The choice between Single Roller and Multi-Roller Scales depends on several factors, including the specific requirements of the application, the budget available, and the level of accuracy needed. While Single Roller Scales are suitable for less demanding applications, Multi-Roller Scales are preferred for high-precision tasks. As industries continue to evolve and demand more sophisticated measurement solutions, the development of advanced belt scale technologies is expected to continue, offering even greater accuracy and efficiency.

Mining, Cement & Building Materials, Power Industry, Iron & Metallurgy, Other in the Global Heavy-Duty Belt Scales Market:

The Global Heavy-Duty Belt Scales Market finds extensive usage across various industries, each with its unique requirements and challenges. In the mining sector, these scales are indispensable for measuring the quantity of extracted materials such as coal, ore, and minerals. Accurate measurement is crucial for inventory management, ensuring that the right amount of material is processed and shipped. This not only helps in optimizing production but also in maintaining compliance with regulatory standards. In the cement and building materials industry, heavy-duty belt scales are used to measure the flow of raw materials like limestone, clay, and gypsum. Precise measurement is essential for maintaining the quality and consistency of the final product. These scales help in optimizing the mix of raw materials, reducing waste, and improving overall efficiency. In the power industry, belt scales are used to measure the flow of coal and other fuels into power plants. Accurate measurement is critical for optimizing fuel usage and ensuring efficient power generation. This helps in reducing operational costs and minimizing environmental impact. In the iron and metallurgy sector, heavy-duty belt scales are used to measure the flow of raw materials like iron ore and scrap metal. Accurate measurement is essential for maintaining the quality of the final product and optimizing production processes. These scales help in reducing waste and improving overall efficiency. Other industries that use heavy-duty belt scales include agriculture, food processing, and waste management. In agriculture, these scales are used to measure the flow of grains and other bulk materials. In food processing, they are used to measure ingredients and ensure consistency in production. In waste management, belt scales are used to measure the flow of waste materials, helping in optimizing recycling processes and reducing landfill usage. Overall, the Global Heavy-Duty Belt Scales Market plays a critical role in various industries, providing accurate and reliable measurement solutions that help in optimizing production, reducing waste, and improving efficiency. As industries continue to evolve and demand more sophisticated measurement solutions, the market for heavy-duty belt scales is expected to grow, offering new opportunities for innovation and development.

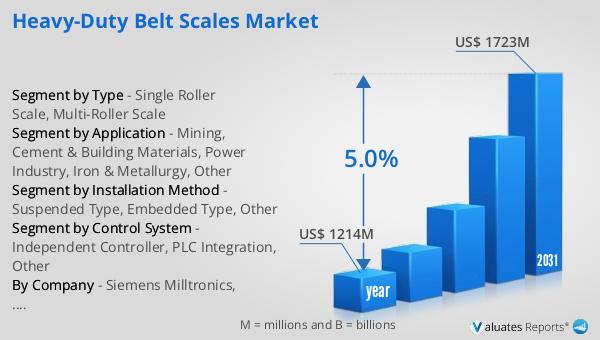

Global Heavy-Duty Belt Scales Market Outlook:

In 2024, the worldwide market for Heavy-Duty Belt Scales was estimated to be worth approximately $1,214 million. Looking ahead, this market is anticipated to expand, reaching an adjusted valuation of around $1,723 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.0% over the forecast period. The steady increase in market size reflects the rising demand for accurate and reliable measurement solutions across various industries. As businesses continue to prioritize efficiency and precision in their operations, the need for advanced belt scale technologies is expected to grow. This market expansion is driven by several factors, including technological advancements, increasing automation in industrial processes, and the growing emphasis on reducing waste and improving productivity. The projected growth in the Heavy-Duty Belt Scales Market underscores the importance of these devices in modern industrial operations. As industries continue to evolve and adapt to changing market conditions, the demand for sophisticated measurement solutions is likely to increase, offering new opportunities for innovation and development in the market. The anticipated growth in the market size highlights the critical role that heavy-duty belt scales play in optimizing production processes and ensuring compliance with industry standards.

| Report Metric | Details |

| Report Name | Heavy-Duty Belt Scales Market |

| Accounted market size in year | US$ 1214 million |

| Forecasted market size in 2031 | US$ 1723 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Installation Method |

|

| Segment by Control System |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens Milltronics, Thayer Scale, Rice Lake Weighing Systems, Schenck Process, Merrick Industries, Tecweigh, Saimo Technology, Yamato Scale, Kanawha Scales & Systems, FLSmidth, Precia Molen, Hardy Process Solutions, MTS Wägetechnik, Sensocar, Avery Weigh-Tronix, Tamtron, Bulk Pro Systems, Scanvaegt |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |