What is Global Vibratory Feeder with Scale Market?

The Global Vibratory Feeder with Scale Market is a specialized segment within the industrial equipment sector, focusing on devices that combine the functions of feeding and weighing materials. These systems are essential in various industries for ensuring precise material handling and measurement. Vibratory feeders with scales are designed to transport and measure bulk materials, such as powders, granules, and small particles, with high accuracy and efficiency. They use vibration to move materials along a conveyor path, while integrated scales provide real-time weight data. This combination allows for seamless integration into automated production lines, enhancing productivity and reducing manual labor. The market for these devices is driven by the increasing demand for automation and precision in manufacturing processes across industries such as food processing, pharmaceuticals, chemicals, and construction. As industries continue to prioritize efficiency and accuracy, the demand for vibratory feeders with scales is expected to grow, offering opportunities for innovation and development in this niche market. The integration of advanced technologies, such as IoT and AI, into these systems is also anticipated to further enhance their capabilities, making them indispensable tools in modern industrial operations.

Powder Type, Particle Type, Other in the Global Vibratory Feeder with Scale Market:

In the Global Vibratory Feeder with Scale Market, the categorization based on material type—Powder Type, Particle Type, and Other—plays a crucial role in determining the specific applications and functionalities of these systems. Powder Type vibratory feeders are designed to handle fine, dry powders that require precise measurement and controlled flow. These feeders are commonly used in industries such as pharmaceuticals, where accurate dosing of powdered ingredients is critical, and in the food industry for handling flour, sugar, and other powdered substances. The design of these feeders ensures minimal dust generation and consistent flow rates, which are essential for maintaining product quality and safety. Particle Type feeders, on the other hand, are tailored for handling granular materials or small particles. These systems are widely used in industries like agriculture, where they facilitate the handling of seeds and grains, and in the chemical industry for transporting granular chemicals. The robust construction of particle type feeders allows them to handle abrasive materials without compromising on accuracy or efficiency. The "Other" category encompasses vibratory feeders designed for specialized applications that do not fall strictly under powder or particle types. This includes feeders for handling mixed materials or those with unique properties that require customized solutions. For instance, in the recycling industry, vibratory feeders are used to sort and transport mixed waste materials, ensuring efficient separation and processing. The versatility of vibratory feeders with scales in handling diverse material types makes them indispensable in modern industrial operations. Their ability to provide precise measurement and control over material flow enhances productivity and reduces waste, contributing to cost savings and improved operational efficiency. As industries continue to evolve and demand more sophisticated material handling solutions, the development of vibratory feeders with advanced features and capabilities is expected to drive market growth. Innovations such as the integration of smart technologies and enhanced material compatibility are likely to expand the applications of these systems, making them even more valuable in a wide range of industrial settings.

Chemical Industry, Food Processing, Pharmaceutical Industry, Building Materials Industry, Other in the Global Vibratory Feeder with Scale Market:

The Global Vibratory Feeder with Scale Market finds extensive usage across various industries, each benefiting from the unique capabilities of these systems. In the Chemical Industry, vibratory feeders with scales are essential for handling and measuring bulk chemicals with precision. These systems ensure accurate dosing and mixing of chemical ingredients, which is crucial for maintaining product quality and safety. The ability to handle a wide range of chemical materials, from powders to granules, makes these feeders versatile tools in chemical manufacturing processes. In the Food Processing industry, vibratory feeders with scales play a vital role in ensuring consistent product quality and efficient production. They are used to transport and measure ingredients such as grains, spices, and additives, ensuring precise formulation and reducing waste. The hygienic design of these feeders, often made from stainless steel, ensures compliance with food safety standards, making them ideal for use in food production environments. The Pharmaceutical Industry relies on vibratory feeders with scales for the accurate handling and measurement of active pharmaceutical ingredients (APIs) and excipients. These systems are critical for ensuring the correct dosage and formulation of pharmaceutical products, which is essential for patient safety and regulatory compliance. The precision and reliability of vibratory feeders make them indispensable in pharmaceutical manufacturing processes. In the Building Materials Industry, vibratory feeders with scales are used to handle and measure materials such as cement, sand, and aggregates. These systems ensure accurate batching and mixing of construction materials, contributing to the quality and durability of the final product. The robust construction of these feeders allows them to withstand the harsh conditions of construction sites, ensuring reliable performance. The "Other" category includes industries such as recycling, agriculture, and mining, where vibratory feeders with scales are used for specialized applications. In recycling, these systems facilitate the sorting and processing of mixed waste materials, enhancing the efficiency of recycling operations. In agriculture, they are used for handling seeds and fertilizers, ensuring precise application and reducing waste. The versatility and precision of vibratory feeders with scales make them valuable assets in a wide range of industrial applications, contributing to improved efficiency, accuracy, and productivity.

Global Vibratory Feeder with Scale Market Outlook:

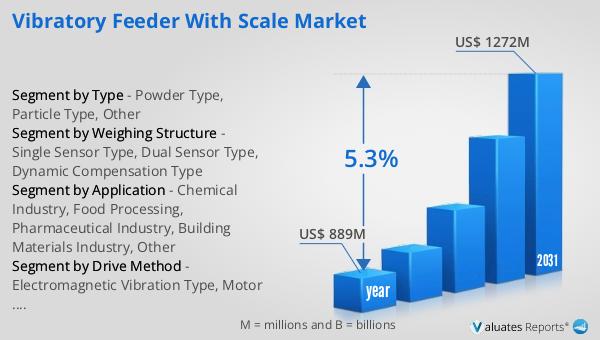

The global market for Vibratory Feeder with Scale was valued at $889 million in 2024, with projections indicating a growth to $1,272 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.3% over the forecast period. This upward trend highlights the increasing demand for these systems across various industries, driven by the need for automation and precision in material handling processes. The market's expansion is fueled by advancements in technology, such as the integration of IoT and AI, which enhance the capabilities of vibratory feeders with scales, making them more efficient and versatile. As industries continue to prioritize efficiency and accuracy, the adoption of these systems is expected to rise, offering opportunities for innovation and development in this niche market. The growing emphasis on sustainability and waste reduction in industrial operations also contributes to the market's growth, as vibratory feeders with scales help optimize material usage and minimize waste. The market's positive outlook reflects the increasing recognition of the value these systems bring to modern industrial operations, making them indispensable tools in achieving operational excellence.

| Report Metric | Details |

| Report Name | Vibratory Feeder with Scale Market |

| Accounted market size in year | US$ 889 million |

| Forecasted market size in 2031 | US$ 1272 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Drive Method |

|

| Segment by Weighing Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thayer Scale, Eriez, Yamato Scale, Schenck Process, Tecweigh, Merrick Industries, Precia Molen, Vibra Maschinenfabrik, Sinfonia Technology, TAD, Coperion, Hardy Process Solutions, Vortex Global, Kanawha Scales & Systems, VMECA, Saimo Technology, Henan Fengbo Automation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |