What is Global Rotor Weigh Feeders Market?

The Global Rotor Weigh Feeders Market is a specialized segment within the industrial equipment sector, focusing on devices that measure and control the flow of bulk materials. These feeders are essential in various industries for ensuring precise material handling and processing. They operate by using a rotor mechanism to weigh and feed materials at a consistent rate, which is crucial for maintaining the quality and efficiency of production processes. The market for rotor weigh feeders is driven by the increasing demand for automation and precision in industries such as cement, power, metallurgy, and chemicals. As industries strive for greater efficiency and reduced waste, the need for accurate and reliable weighing systems becomes more pronounced. The global market is characterized by technological advancements, with manufacturers continuously innovating to offer more accurate, durable, and user-friendly solutions. The integration of digital technologies and IoT in rotor weigh feeders is also a growing trend, allowing for better monitoring and control of material flow. This market is expected to grow steadily as industries continue to prioritize efficiency and precision in their operations.

Powder Type, Particle Type, Other in the Global Rotor Weigh Feeders Market:

In the Global Rotor Weigh Feeders Market, products are categorized based on the type of material they handle, namely powder type, particle type, and others. Each category addresses specific industrial needs and challenges. Powder type rotor weigh feeders are designed to handle fine, granular materials that require precise measurement and control. These feeders are crucial in industries where the consistency of powder flow can significantly impact product quality, such as in the pharmaceutical and food processing sectors. The design of these feeders often includes features to prevent clogging and ensure smooth operation, even with materials that have a tendency to compact or stick. Particle type feeders, on the other hand, are tailored for handling larger, more granular materials. These feeders are commonly used in industries like construction and mining, where materials such as gravel, sand, and crushed stone need to be measured and fed into processing systems accurately. The robust design of particle type feeders allows them to withstand the abrasive nature of these materials, ensuring longevity and reliability. The 'other' category in rotor weigh feeders encompasses a range of specialized feeders designed for unique applications that do not fit neatly into the powder or particle categories. This can include feeders for fibrous materials, liquids, or mixed material streams. These feeders are often customized to meet the specific needs of a particular industry or application, offering flexibility and adaptability. The demand for these various types of rotor weigh feeders is driven by the diverse needs of industries seeking to optimize their material handling processes. As industries continue to evolve and face new challenges, the development and refinement of rotor weigh feeders will remain a critical area of focus. Manufacturers are investing in research and development to create feeders that are not only more accurate and efficient but also more environmentally friendly and cost-effective. The integration of advanced technologies, such as automation and IoT, is also playing a significant role in the evolution of rotor weigh feeders, enabling better data collection and process optimization. As a result, the Global Rotor Weigh Feeders Market is poised for continued growth and innovation, meeting the ever-changing demands of modern industries.

Cement Industry, Power Industry, Metallurgical Industry, Chemical Industry, Other in the Global Rotor Weigh Feeders Market:

The Global Rotor Weigh Feeders Market finds extensive application across various industries, each with unique requirements and challenges. In the cement industry, rotor weigh feeders are indispensable for ensuring the precise measurement and feeding of raw materials such as limestone, clay, and gypsum. Accurate feeding is crucial for maintaining the quality and consistency of cement production, as even slight variations in material composition can affect the final product. Rotor weigh feeders help optimize the production process, reduce waste, and improve overall efficiency, making them a vital component in cement manufacturing plants. In the power industry, rotor weigh feeders play a critical role in the handling of coal and other fuels used in power generation. These feeders ensure that the right amount of fuel is fed into the combustion chamber, optimizing the efficiency of the power plant and reducing emissions. The ability to accurately control fuel flow is essential for maintaining stable and efficient power generation, making rotor weigh feeders an integral part of modern power plants. The metallurgical industry also relies heavily on rotor weigh feeders for the precise handling of raw materials such as ores, concentrates, and additives. Accurate measurement and feeding of these materials are crucial for maintaining the quality and efficiency of metallurgical processes, such as smelting and refining. Rotor weigh feeders help ensure that the right proportions of materials are used, optimizing the production process and reducing waste. In the chemical industry, rotor weigh feeders are used to handle a wide range of materials, from powders and granules to liquids and slurries. Accurate measurement and control of material flow are essential for maintaining the quality and consistency of chemical products, as well as ensuring the safety and efficiency of chemical processes. Rotor weigh feeders help optimize the production process, reduce waste, and improve overall efficiency, making them a vital component in chemical manufacturing plants. Other industries, such as food processing, pharmaceuticals, and agriculture, also benefit from the use of rotor weigh feeders. These feeders help ensure the accurate measurement and feeding of materials, optimizing production processes and improving product quality. As industries continue to evolve and face new challenges, the demand for rotor weigh feeders is expected to grow, driving innovation and development in this critical market segment.

Global Rotor Weigh Feeders Market Outlook:

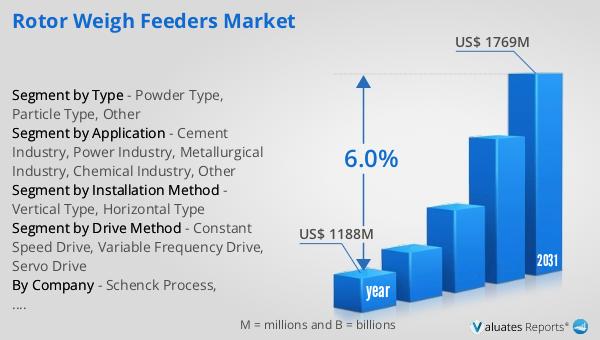

The global market for rotor weigh feeders is experiencing significant growth, with its value estimated at $1,188 million in 2024. This market is projected to expand to a revised size of $1,769 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.0% during the forecast period. This growth is driven by the increasing demand for precision and efficiency in material handling across various industries. As industries continue to prioritize automation and optimization, the need for accurate and reliable weighing systems becomes more pronounced. Rotor weigh feeders play a crucial role in ensuring the precise measurement and control of material flow, making them an essential component in modern industrial processes. The market's expansion is also fueled by technological advancements, with manufacturers continuously innovating to offer more accurate, durable, and user-friendly solutions. The integration of digital technologies and IoT in rotor weigh feeders is a growing trend, allowing for better monitoring and control of material flow. As a result, the global rotor weigh feeders market is poised for continued growth and innovation, meeting the ever-changing demands of modern industries.

| Report Metric | Details |

| Report Name | Rotor Weigh Feeders Market |

| Accounted market size in year | US$ 1188 million |

| Forecasted market size in 2031 | US$ 1769 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Drive Method |

|

| Segment by Installation Method |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Schenck Process, FLSmidth, Merrick Industries, MTS Wägetechnik, Yamato Scale, Tecweigh, Precia Molen, Saimo Technology, Thayer Scale, Siemens Milltronics, Hardy Process Solutions, Acrison Inc., Vortex Global, VIBRA Maschinenfabrik, VMECA, Kanawha Scales & Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |