What is Global Autologous Platelet Rich Plasma (PRP) Market?

The global Autologous Platelet Rich Plasma (PRP) market is a rapidly growing sector within the medical field. PRP is a concentration of platelets derived from the patient's own blood, which is then injected back into their body to promote healing and tissue regeneration. This market is driven by the increasing demand for minimally invasive procedures, advancements in medical technology, and the rising prevalence of chronic diseases and sports injuries. PRP therapy is used in various medical fields, including orthopedics, dermatology, and dentistry, due to its potential to accelerate the healing process and improve patient outcomes. The market is also benefiting from the growing awareness among patients and healthcare providers about the benefits of PRP therapy. As a result, the global Autologous Platelet Rich Plasma market is expected to continue its growth trajectory in the coming years, offering significant opportunities for both existing players and new entrants in the market.

P-PRP, L-PRP, PRF in the Global Autologous Platelet Rich Plasma (PRP) Market:

In the context of the Global Autologous Platelet Rich Plasma (PRP) market, there are different types of PRP preparations, including Pure Platelet-Rich Plasma (P-PRP), Leukocyte-Platelet Rich Plasma (L-PRP), and Platelet-Rich Fibrin (PRF). P-PRP is characterized by a high concentration of platelets with minimal leukocytes, making it ideal for applications where inflammation needs to be minimized. This type of PRP is commonly used in aesthetic medicine and dermatology for procedures like skin rejuvenation and hair restoration. On the other hand, L-PRP contains a higher concentration of leukocytes along with platelets, which can enhance the inflammatory response and is often used in orthopedic and sports medicine to treat conditions like tendonitis and ligament injuries. PRF, meanwhile, is a newer generation of PRP that includes a fibrin matrix, which can provide a more sustained release of growth factors and is used in dental and maxillofacial surgery to promote bone and tissue regeneration. Each type of PRP has its unique advantages and is selected based on the specific medical condition and desired therapeutic outcomes. The choice between P-PRP, L-PRP, and PRF depends on factors such as the patient's health status, the nature of the injury or condition, and the clinical goals of the treatment.

Orthopedic Surgery, Plastic Surgery, General Surgery, Others in the Global Autologous Platelet Rich Plasma (PRP) Market:

The usage of Global Autologous Platelet Rich Plasma (PRP) in various medical fields is extensive and diverse. In orthopedic surgery, PRP is used to treat a range of musculoskeletal conditions, including osteoarthritis, tendon injuries, and ligament sprains. The growth factors in PRP can accelerate the healing process, reduce pain, and improve joint function, making it a valuable adjunct to traditional orthopedic treatments. In plastic surgery, PRP is employed for facial rejuvenation, scar reduction, and hair restoration. The regenerative properties of PRP can enhance the results of cosmetic procedures, leading to improved skin texture, reduced wrinkles, and increased hair density. General surgery also benefits from PRP, particularly in wound healing and tissue repair. PRP can be applied to surgical sites to promote faster recovery, reduce the risk of infection, and minimize scarring. Additionally, PRP is used in other medical fields such as dentistry, where it aids in the healing of periodontal and oral surgery procedures, and in sports medicine, where it helps athletes recover from injuries more quickly. The versatility of PRP therapy makes it a valuable tool across various medical disciplines, offering patients a natural and effective treatment option.

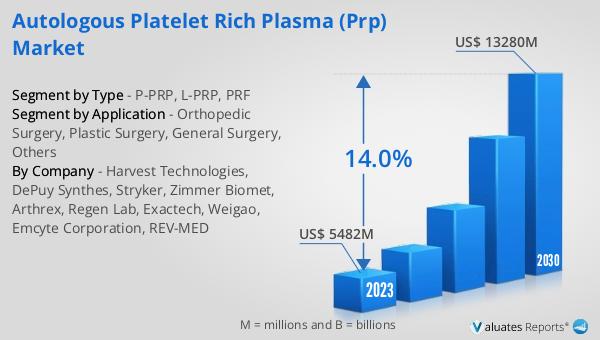

Global Autologous Platelet Rich Plasma (PRP) Market Outlook:

The global Autologous Platelet Rich Plasma (PRP) market was valued at $5,482 million in 2023 and is projected to reach $13,280 million by 2030, reflecting a compound annual growth rate (CAGR) of 14.0% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing adoption of PRP therapy across various medical fields, advancements in PRP preparation techniques, and the rising awareness of the benefits of PRP among patients and healthcare providers. The market's expansion is also supported by the growing prevalence of chronic diseases, sports injuries, and the demand for minimally invasive procedures. As more clinical studies validate the efficacy of PRP therapy, its acceptance and utilization are expected to increase, further propelling the market's growth. The promising outlook for the global Autologous Platelet Rich Plasma market presents numerous opportunities for innovation and development, making it an attractive area for investment and research.

| Report Metric | Details |

| Report Name | Autologous Platelet Rich Plasma (PRP) Market |

| Accounted market size in 2023 | US$ 5482 million |

| Forecasted market size in 2030 | US$ 13280 million |

| CAGR | 14.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Harvest Technologies, DePuy Synthes, Stryker, Zimmer Biomet, Arthrex, Regen Lab, Exactech, Weigao, Emcyte Corporation, REV-MED |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |