What is High Alumina Refractory Material - Global Market?

High alumina refractory materials are specialized materials used in high-temperature environments due to their ability to withstand extreme heat and resist chemical corrosion. These materials are primarily composed of aluminum oxide (Al2O3), which gives them their high melting point and excellent thermal stability. They are widely used in industries such as steel, cement, glass, and ceramics, where they serve as linings for furnaces, kilns, and other high-temperature processing equipment. The global market for high alumina refractory materials is driven by the growing demand for these materials in industrial applications, particularly in emerging economies where industrialization is on the rise. As industries continue to expand and modernize, the need for durable and efficient refractory materials increases, making high alumina refractories a critical component in maintaining operational efficiency and safety. The market is characterized by a diverse range of products, each tailored to specific industrial needs, and is supported by ongoing research and development efforts aimed at enhancing the performance and sustainability of these materials.

0.4, 0.55, 0.7, 0.8, Other in the High Alumina Refractory Material - Global Market:

High alumina refractory materials are categorized based on their alumina content, which significantly influences their properties and applications. The categories include 0.4, 0.55, 0.7, 0.8, and other alumina content levels, each offering distinct characteristics suited for various industrial uses. The 0.4 alumina content materials are typically used in applications where moderate thermal resistance is required. These materials are cost-effective and provide adequate performance for less demanding environments. The 0.55 alumina content materials offer improved thermal stability and are often used in industries where higher temperatures are encountered, such as in certain sections of steel and cement manufacturing. The 0.7 alumina content materials are known for their excellent resistance to thermal shock and chemical attack, making them ideal for more aggressive environments like glass production and non-ferrous metal processing. The 0.8 alumina content materials represent the higher end of the spectrum, providing superior performance in the most demanding applications. These materials are used in critical areas of furnaces and kilns where maximum durability and longevity are required. Other alumina content levels are tailored for specific niche applications, offering customized solutions for unique industrial challenges. The global market for high alumina refractory materials is shaped by the diverse needs of these industries, with manufacturers continually innovating to meet the evolving demands of their customers. As industries strive for greater efficiency and sustainability, the development of advanced refractory materials with enhanced properties is a key focus area. This includes efforts to improve the thermal efficiency of these materials, reduce their environmental impact, and extend their service life. The market is also influenced by regulatory standards and environmental considerations, which drive the adoption of more sustainable and eco-friendly refractory solutions. Overall, the high alumina refractory material market is a dynamic and evolving sector, characterized by a wide range of products and applications that cater to the diverse needs of modern industries.

Special Road & Construction, Industry Kiln, Sewer Applications, Other in the High Alumina Refractory Material - Global Market:

High alumina refractory materials play a crucial role in various applications, including special road and construction, industry kilns, sewer applications, and other specialized uses. In the realm of special road and construction, these materials are used to enhance the durability and longevity of infrastructure projects. Their high thermal resistance and mechanical strength make them ideal for use in environments where extreme temperatures and harsh conditions are prevalent, such as in the construction of tunnels and bridges. In industrial kilns, high alumina refractory materials are essential for lining the interiors of these high-temperature processing units. They provide the necessary thermal insulation and protection against chemical corrosion, ensuring the efficient and safe operation of kilns used in industries like ceramics, glass, and metallurgy. In sewer applications, high alumina refractories are used to line sewer pipes and other components exposed to corrosive substances and high temperatures. Their resistance to chemical attack and thermal shock makes them suitable for maintaining the integrity and functionality of sewer systems. Other specialized applications of high alumina refractory materials include their use in the aerospace and defense industries, where they are employed in the production of heat shields and other components that require exceptional thermal resistance. The versatility and adaptability of high alumina refractory materials make them indispensable in a wide range of industrial and infrastructure applications, contributing to the efficiency, safety, and sustainability of these sectors. As industries continue to evolve and face new challenges, the demand for high-performance refractory materials is expected to grow, driving innovation and development in this critical market.

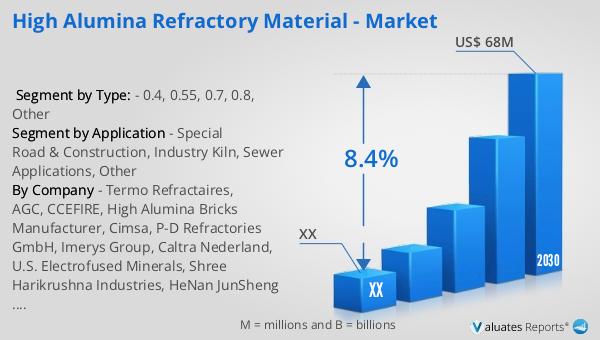

High Alumina Refractory Material - Global Market Outlook:

The global market for high alumina refractory materials was valued at approximately US$ 34 million in 2023. It is projected to expand to a revised size of US$ 68 million by 2030, reflecting a compound annual growth rate (CAGR) of 8.4% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-performance refractory materials across various industries. In North America, the market for high alumina refractory materials was valued at a certain amount in 2023 and is expected to reach a specific value by 2030, with a CAGR of a certain percentage during the forecast period from 2024 through 2030. This regional growth is driven by the robust industrial base and the continuous advancements in manufacturing technologies that require high-quality refractory solutions. The market outlook highlights the significant opportunities for growth and development in the high alumina refractory material sector, as industries seek to enhance their operational efficiency and sustainability through the adoption of advanced materials. The increasing focus on reducing environmental impact and improving energy efficiency further underscores the importance of high alumina refractories in the global market landscape.

| Report Metric | Details |

| Report Name | High Alumina Refractory Material - Market |

| Forecasted market size in 2030 | US$ 68 million |

| CAGR | 8.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Termo Refractaires, AGC, CCEFIRE, High Alumina Bricks Manufacturer, Cimsa, P-D Refractories GmbH, Imerys Group, Caltra Nederland, U.S. Electrofused Minerals, Shree Harikrushna Industries, HeNan JunSheng Refractories Limited, Zhengzhou Dengfeng Smelting Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |