What is Rubber Mixer - Global Market?

Rubber mixers are essential machines used in the rubber industry to blend raw rubber with various additives, such as fillers, oils, and chemicals, to create a homogeneous rubber compound. This process is crucial for producing rubber products with specific properties and characteristics. The global market for rubber mixers is driven by the increasing demand for rubber products across various industries, including automotive, aerospace, construction, and consumer goods. As industries continue to innovate and develop new rubber-based products, the need for efficient and reliable rubber mixing equipment grows. Rubber mixers come in different types, such as roll mills and internal mixers, each offering unique advantages and capabilities. The market is characterized by technological advancements aimed at improving mixing efficiency, reducing energy consumption, and enhancing the quality of the final rubber compound. As a result, manufacturers are investing in research and development to create more advanced and automated rubber mixers that meet the evolving needs of the industry. The global rubber mixer market is expected to experience steady growth as industries continue to rely on rubber products for various applications.

Roll Mills, Internal Mixers in the Rubber Mixer - Global Market:

Roll mills and internal mixers are two primary types of rubber mixers used in the global market, each serving distinct purposes in the rubber compounding process. Roll mills, also known as two-roll mills, consist of two horizontally placed rolls that rotate in opposite directions. These machines are primarily used for mastication and mixing of rubber compounds. The rolls are adjustable, allowing operators to control the gap between them, which in turn affects the shearing and mixing action. Roll mills are favored for their simplicity and ability to handle a wide range of rubber compounds. They are particularly useful for small-scale production and laboratory settings where precise control over the mixing process is required. On the other hand, internal mixers, such as the Banbury mixer, are more complex machines designed for large-scale production. These mixers consist of a chamber with two rotors that rotate in opposite directions, creating a high-shear environment that efficiently blends rubber with additives. Internal mixers are known for their ability to produce uniform and consistent rubber compounds, making them ideal for mass production in industries like automotive and aerospace. They offer advantages such as reduced mixing time, improved dispersion of fillers, and enhanced control over the mixing process. The choice between roll mills and internal mixers depends on factors such as production scale, desired compound properties, and specific industry requirements. As the global market for rubber mixers continues to evolve, manufacturers are focusing on developing more advanced and efficient machines that cater to the diverse needs of the rubber industry. This includes innovations in automation, energy efficiency, and process control, which are essential for meeting the growing demand for high-quality rubber products.

Aerospace, Automotive, Other in the Rubber Mixer - Global Market:

Rubber mixers play a crucial role in various industries, including aerospace, automotive, and others, by providing the necessary equipment for producing high-quality rubber compounds. In the aerospace industry, rubber mixers are used to create rubber compounds that meet the stringent requirements for aircraft components, such as seals, gaskets, and vibration dampeners. These components must withstand extreme temperatures, pressures, and environmental conditions, making the quality and consistency of the rubber compound critical. Rubber mixers enable manufacturers to achieve the precise formulation needed for these demanding applications. In the automotive industry, rubber mixers are essential for producing a wide range of rubber components, including tires, hoses, belts, and seals. The automotive sector demands rubber compounds with specific properties, such as durability, flexibility, and resistance to heat and chemicals. Rubber mixers allow manufacturers to tailor the rubber compounds to meet these requirements, ensuring the performance and safety of automotive components. Additionally, the growing trend towards electric vehicles and sustainable materials is driving innovation in rubber mixing technology to produce eco-friendly rubber compounds. Beyond aerospace and automotive, rubber mixers are used in various other industries, such as construction, consumer goods, and healthcare. In construction, rubber compounds are used for roofing materials, flooring, and insulation, where durability and weather resistance are essential. In the consumer goods sector, rubber is used in products like footwear, sporting goods, and household items, requiring rubber mixers to produce compounds with specific textures and properties. In healthcare, rubber compounds are used for medical devices and equipment, where biocompatibility and safety are paramount. The versatility of rubber mixers makes them indispensable across these diverse industries, driving the global market's growth as demand for specialized rubber products continues to rise.

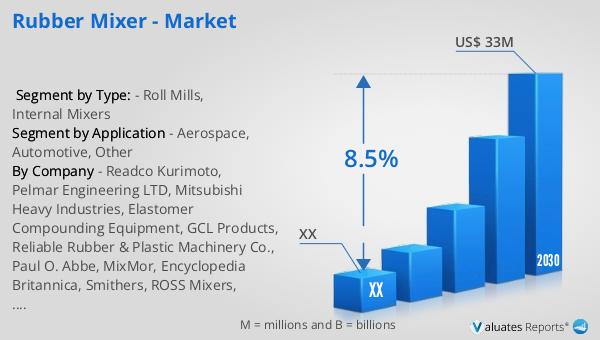

Rubber Mixer - Global Market Outlook:

The global market for rubber mixers was valued at approximately $12 million in 2023, with projections indicating a significant increase to around $33 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. The North American market for rubber mixers, although not specified in exact figures, is anticipated to follow a similar upward trajectory, contributing to the overall expansion of the global market. This growth can be attributed to the increasing demand for rubber products across various industries, including automotive, aerospace, and construction, which rely on high-quality rubber compounds for their products. As industries continue to innovate and develop new applications for rubber, the need for efficient and reliable rubber mixing equipment becomes more critical. Manufacturers are investing in research and development to create advanced rubber mixers that meet the evolving needs of the market, focusing on improving mixing efficiency, reducing energy consumption, and enhancing the quality of the final rubber compound. This trend is expected to drive the growth of the rubber mixer market, providing opportunities for manufacturers to expand their product offerings and capture a larger share of the market.

| Report Metric | Details |

| Report Name | Rubber Mixer - Market |

| Forecasted market size in 2030 | US$ 33 million |

| CAGR | 8.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Readco Kurimoto, Pelmar Engineering LTD, Mitsubishi Heavy Industries, Elastomer Compounding Equipment, GCL Products, Reliable Rubber & Plastic Machinery Co., Paul O. Abbe, MixMor, Encyclopedia Britannica, Smithers, ROSS Mixers, Resodyn Acoustic Mixers, POUSTHOMIS, Proquip, Inc., EcReCon, Inc., KOBE STEEL, LTD., HF Mixing Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |