What is Food Metal Detector - Global Market?

Food metal detectors are essential devices used in the food industry to ensure the safety and quality of food products by detecting and removing metal contaminants. These contaminants can enter food products at various stages of production, from raw material handling to packaging. The global market for food metal detectors is driven by the increasing demand for food safety and stringent regulations imposed by food safety authorities worldwide. These detectors are designed to identify ferrous, non-ferrous, and stainless steel metals, which could potentially harm consumers or damage machinery. The technology behind these detectors has evolved significantly, offering high sensitivity and reliability. They are widely used across various food processing sectors, including bakery, seafood, frozen foods, spices, and sugar, among others. The market is characterized by continuous innovation, with manufacturers focusing on enhancing detection capabilities and integrating advanced features like digital signal processing and automatic calibration. As food safety concerns continue to rise, the demand for efficient and reliable food metal detectors is expected to grow, making them an indispensable part of the food processing industry.

Bakery Food Metal Detector, Sea Foods Metal Detectors, Frozen Food Metal Detector, Spice Metal Detector, Sugar Metal Detector, Others in the Food Metal Detector - Global Market:

Bakery food metal detectors are specifically designed to cater to the unique challenges faced in the bakery industry. These detectors must be sensitive enough to detect metal contaminants in a variety of bakery products, from bread and pastries to cakes and cookies. The presence of metal contaminants in bakery products can occur due to broken machinery parts or during the handling and packaging processes. Bakery food metal detectors are equipped with advanced technology to ensure that even the smallest metal particles are detected and removed, thereby safeguarding consumer health and maintaining product quality. Similarly, seafood metal detectors are crucial in the seafood processing industry, where metal contamination can occur during the cleaning, cutting, and packaging stages. These detectors are designed to operate in wet and salty environments, ensuring that they can effectively detect metal contaminants without being affected by the challenging conditions. Frozen food metal detectors are used to inspect frozen products, which can pose unique challenges due to their low temperatures and varying densities. These detectors are engineered to maintain high sensitivity and accuracy, even in sub-zero conditions, ensuring that frozen foods are free from metal contaminants. Spice metal detectors are essential in the spice industry, where metal contamination can occur during grinding and packaging. These detectors are designed to handle the fine and often dusty nature of spices, ensuring that they can accurately detect and remove metal particles. Sugar metal detectors are used in the sugar processing industry to ensure that sugar products are free from metal contaminants. These detectors must be able to handle the fine and granular nature of sugar, ensuring that they can effectively detect and remove any metal particles. Other food metal detectors are used in various other sectors of the food industry, including dairy, meat, and beverages, among others. These detectors are designed to meet the specific needs of each sector, ensuring that they can effectively detect and remove metal contaminants, thereby ensuring the safety and quality of food products.

Food and Beverages, Others in the Food Metal Detector - Global Market:

The usage of food metal detectors in the food and beverages industry is extensive and critical for maintaining food safety standards. In the food industry, these detectors are used at various stages of production, from raw material inspection to final product packaging. They help in identifying and removing metal contaminants that may have entered the food products during processing, thereby preventing potential harm to consumers and ensuring compliance with food safety regulations. In the beverages sector, metal detectors are used to inspect liquid products, ensuring that they are free from metal contaminants. This is particularly important in the production of bottled and canned beverages, where metal contamination can occur during the filling and sealing processes. The use of metal detectors in the food and beverages industry not only helps in maintaining product quality but also enhances consumer trust and brand reputation. In addition to the food and beverages industry, food metal detectors are also used in other sectors, such as pharmaceuticals and cosmetics, where product safety and quality are of utmost importance. In these industries, metal detectors are used to inspect raw materials and finished products, ensuring that they are free from metal contaminants. The use of metal detectors in these sectors helps in maintaining product integrity and compliance with industry standards and regulations. Overall, the usage of food metal detectors in various industries is crucial for ensuring product safety and quality, thereby protecting consumers and enhancing brand reputation.

Food Metal Detector - Global Market Outlook:

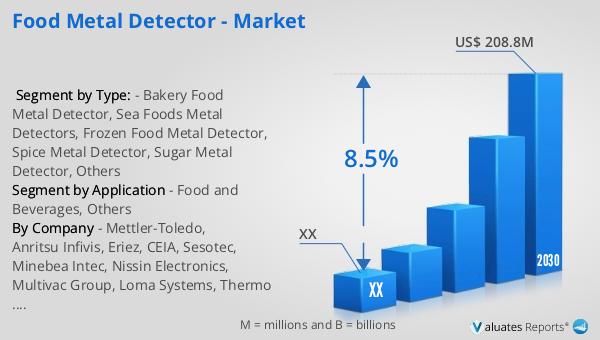

The global market for food metal detectors was valued at approximately $148 million in 2023, with projections indicating a growth to around $208.8 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.5% from 2024 to 2030. The North American market, a significant segment of the global landscape, was valued at an undisclosed amount in 2023, with expectations of reaching a higher value by 2030, although specific figures and growth rates for this region were not provided. This upward trend in the market is driven by increasing awareness and demand for food safety, coupled with stringent regulations imposed by food safety authorities. The advancements in technology, leading to more efficient and reliable metal detection systems, also contribute to this growth. As industries continue to prioritize consumer safety and product quality, the demand for food metal detectors is anticipated to rise, making them an integral part of the food processing and manufacturing sectors. The market's expansion reflects the growing emphasis on ensuring that food products are free from metal contaminants, thereby safeguarding consumer health and enhancing brand reputation.

| Report Metric | Details |

| Report Name | Food Metal Detector - Market |

| Forecasted market size in 2030 | US$ 208.8 million |

| CAGR | 8.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mettler-Toledo, Anritsu Infivis, Eriez, CEIA, Sesotec, Minebea Intec, Nissin Electronics, Multivac Group, Loma Systems, Thermo Fisher, Bizerba, Ishida, WIPOTEC-OCS, Mesutronic, Fortress Technology, Nikka Densok, Shanghai Techik, Gaojing, Easyweigh, Qingdao Baijing, COSO, JUZHENG Electronic and Technology, Dongguan Shanan, Dongguan Lianxin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |