What is Rubber Peptizers - Global Market?

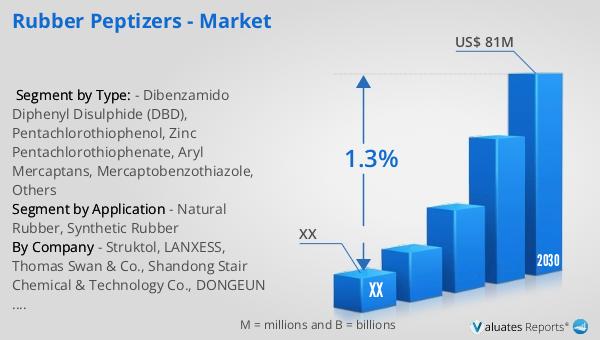

Rubber peptizers are specialized chemical agents used in the rubber industry to improve the processing of rubber compounds. These agents work by breaking down the molecular structure of rubber, making it easier to process and mix with other ingredients. The global market for rubber peptizers is a niche but essential segment within the broader rubber industry. As of 2023, the market was valued at approximately US$ 60 million, with expectations to grow to US$ 81 million by 2030, reflecting a compound annual growth rate (CAGR) of 1.3% from 2024 to 2030. This growth is driven by the increasing demand for high-performance rubber products across various industries, including automotive, construction, and consumer goods. The North American market, in particular, plays a significant role in this growth, although specific figures for this region were not provided. The use of rubber peptizers is crucial in enhancing the efficiency of rubber processing, reducing energy consumption, and improving the quality of the final product. As industries continue to seek more sustainable and cost-effective manufacturing processes, the demand for rubber peptizers is expected to rise, albeit at a modest pace.

Dibenzamido Diphenyl Disulphide (DBD), Pentachlorothiophenol, Zinc Pentachlorothiophenate, Aryl Mercaptans, Mercaptobenzothiazole, Others in the Rubber Peptizers - Global Market:

Dibenzamido Diphenyl Disulphide (DBD) is one of the key compounds used as a rubber peptizer. It is known for its ability to effectively reduce the viscosity of rubber, making it easier to process. DBD is particularly useful in the production of natural rubber, where it helps in breaking down the polymer chains, thus facilitating better mixing and processing. This compound is favored for its efficiency and the quality of the rubber it helps produce. Pentachlorothiophenol is another important peptizer, often used in synthetic rubber processing. It acts by softening the rubber, allowing for easier mixing and shaping. Its effectiveness in reducing the energy required for rubber processing makes it a popular choice in the industry. Zinc Pentachlorothiophenate is a derivative of pentachlorothiophenol and is used for similar purposes. It offers the added benefit of being a more stable compound, which can enhance the durability of the rubber products. Aryl Mercaptans are a group of compounds used as peptizers, known for their ability to improve the flow properties of rubber. They are particularly effective in synthetic rubber applications, where they help in achieving a more uniform product. Mercaptobenzothiazole is another compound used in the rubber industry, primarily as an accelerator, but it also has peptizing properties. It helps in speeding up the vulcanization process, which is crucial for producing high-quality rubber products. Other compounds used as rubber peptizers include various organic and inorganic chemicals that aid in the processing of rubber. These compounds are selected based on the specific requirements of the rubber being processed, such as the type of rubber, the desired properties of the final product, and the processing conditions. The global market for these compounds is driven by the demand for high-performance rubber products, which require efficient and effective processing aids. As industries continue to innovate and develop new rubber products, the demand for these peptizers is expected to grow, albeit at a steady pace.

Natural Rubber, Synthetic Rubber in the Rubber Peptizers - Global Market:

Rubber peptizers play a crucial role in the processing of both natural and synthetic rubber. In the case of natural rubber, peptizers are used to break down the long polymer chains, making the rubber more pliable and easier to work with. This is particularly important in the initial stages of rubber processing, where the raw rubber needs to be softened and mixed with other ingredients. The use of peptizers in natural rubber processing helps in reducing the energy required for mixing and shaping, thus improving the efficiency of the manufacturing process. Additionally, peptizers help in achieving a more uniform product, which is essential for producing high-quality rubber goods. In synthetic rubber processing, peptizers are used to enhance the flow properties of the rubber, making it easier to mold and shape. This is particularly important in the production of complex rubber products, where precise shaping and molding are required. Peptizers help in reducing the viscosity of synthetic rubber, allowing for better mixing and processing. This not only improves the efficiency of the manufacturing process but also enhances the quality of the final product. The use of peptizers in synthetic rubber processing is driven by the demand for high-performance rubber products, which require precise and efficient processing techniques. As industries continue to innovate and develop new rubber products, the demand for peptizers in both natural and synthetic rubber processing is expected to grow. The global market for rubber peptizers is driven by the need for efficient and effective processing aids, which can enhance the quality and performance of rubber products. As industries continue to seek more sustainable and cost-effective manufacturing processes, the demand for rubber peptizers is expected to rise, albeit at a modest pace.

Rubber Peptizers - Global Market Outlook:

The global market for rubber peptizers was valued at approximately US$ 60 million in 2023, with projections indicating a growth to US$ 81 million by 2030. This growth represents a compound annual growth rate (CAGR) of 1.3% from 2024 to 2030. The North American market, although specific figures were not provided, is expected to contribute significantly to this growth. The demand for rubber peptizers is driven by the increasing need for high-performance rubber products across various industries, including automotive, construction, and consumer goods. These industries require efficient and effective processing aids to enhance the quality and performance of their rubber products. The use of rubber peptizers helps in reducing energy consumption, improving processing efficiency, and achieving a more uniform product. As industries continue to innovate and develop new rubber products, the demand for rubber peptizers is expected to grow, albeit at a steady pace. The market outlook for rubber peptizers is positive, with steady growth expected over the forecast period. This growth is driven by the increasing demand for high-performance rubber products and the need for efficient and effective processing aids. As industries continue to seek more sustainable and cost-effective manufacturing processes, the demand for rubber peptizers is expected to rise, albeit at a modest pace.

| Report Metric | Details |

| Report Name | Rubber Peptizers - Market |

| Forecasted market size in 2030 | US$ 81 million |

| CAGR | 1.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Struktol, LANXESS, Thomas Swan & Co., Shandong Stair Chemical & Technology Co., DONGEUN CO., Zhengzhou Double Vigour Chemical Product, Taizhou Huangyan Donghai Chemical Co., Acmechem, Akrochem, HENAN CONNECT RUBBER CHEMICAL, Kettlitz-Chemie GmbH & Co, King Industries, Inc., CHEMSPEC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |