What is VCI Masterbatch - Global Market?

VCI Masterbatch, or Volatile Corrosion Inhibitor Masterbatch, is a specialized product used in the packaging industry to protect metal products from corrosion during storage and transportation. This masterbatch is a concentrated mixture of VCI chemicals and a polymer carrier, which can be added to plastic films, bags, or other packaging materials. When used, it releases VCI molecules that form a protective layer on the surface of metal items, preventing moisture and oxygen from causing rust and corrosion. The global market for VCI Masterbatch is driven by the increasing demand for effective corrosion protection solutions in various industries, including automotive, electronics, and heavy machinery. As industries continue to expand globally, the need for reliable and efficient packaging solutions that ensure the longevity and integrity of metal products becomes more critical. The VCI Masterbatch market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the effectiveness and environmental sustainability of their products. This market is expected to grow steadily as more industries recognize the benefits of using VCI technology to protect their valuable metal components and products.

LDPE, LLDPE, HDPE in the VCI Masterbatch - Global Market:

LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), and HDPE (High-Density Polyethylene) are three types of polyethylene that serve as carriers in VCI Masterbatch formulations. Each type of polyethylene has distinct properties that make it suitable for different applications in the VCI Masterbatch market. LDPE is known for its flexibility, transparency, and ease of processing, making it an ideal choice for applications where these characteristics are essential. It is commonly used in the production of films and bags that require a certain degree of flexibility and clarity. In the context of VCI Masterbatch, LDPE-based formulations are often used in packaging applications where the protection of metal products from corrosion is necessary, and the packaging material needs to be flexible and easy to handle. LLDPE, on the other hand, offers improved tensile strength and puncture resistance compared to LDPE, making it suitable for more demanding applications. Its linear structure allows for better load-bearing capacity, which is beneficial in packaging applications where the material needs to withstand mechanical stress. LLDPE-based VCI Masterbatch formulations are often used in applications where enhanced durability and strength are required, such as in the packaging of heavy or sharp metal components. HDPE is characterized by its high strength-to-density ratio, making it an excellent choice for applications that require robust and durable packaging materials. HDPE-based VCI Masterbatch formulations are typically used in applications where maximum protection and rigidity are needed, such as in the packaging of large or heavy metal products. The choice between LDPE, LLDPE, and HDPE as a carrier in VCI Masterbatch formulations depends on the specific requirements of the application, including the type of metal being protected, the environmental conditions, and the desired properties of the packaging material. Each type of polyethylene offers unique advantages, and manufacturers often tailor their VCI Masterbatch formulations to meet the specific needs of their customers. As the global market for VCI Masterbatch continues to grow, the demand for polyethylene-based formulations is expected to increase, driven by the need for effective and versatile corrosion protection solutions.

Metal, Automatic, Mechanical Equipment in the VCI Masterbatch - Global Market:

VCI Masterbatch is widely used in various industries to protect metal products from corrosion, and its applications in the metal, automotive, and mechanical equipment sectors are particularly significant. In the metal industry, VCI Masterbatch is used to produce packaging materials that protect metal products such as steel coils, sheets, and pipes from rust and corrosion during storage and transportation. The protective layer formed by the VCI molecules prevents moisture and oxygen from reaching the metal surface, ensuring that the products remain in pristine condition until they reach their final destination. This is especially important in the metal industry, where the quality and integrity of the products are critical to their performance and value. In the automotive industry, VCI Masterbatch is used to protect metal components and parts during manufacturing, assembly, and transportation. Automotive parts such as engines, transmissions, and brake systems are often made of metal and are susceptible to corrosion if not properly protected. VCI Masterbatch provides an effective solution by creating a protective barrier that prevents corrosion and extends the lifespan of these critical components. This not only helps to maintain the quality and performance of the vehicles but also reduces the need for costly repairs and replacements. In the mechanical equipment sector, VCI Masterbatch is used to protect machinery and equipment from corrosion during storage and transportation. Mechanical equipment often consists of metal parts that are exposed to harsh environmental conditions, making them vulnerable to rust and corrosion. By using VCI Masterbatch in the packaging materials, manufacturers can ensure that their equipment remains in optimal condition, reducing the risk of damage and prolonging the lifespan of the machinery. This is particularly important in industries such as construction, mining, and agriculture, where the reliability and durability of the equipment are crucial to the success of the operations. Overall, the use of VCI Masterbatch in these industries provides a cost-effective and efficient solution for protecting metal products from corrosion, ensuring their quality and performance throughout their lifecycle.

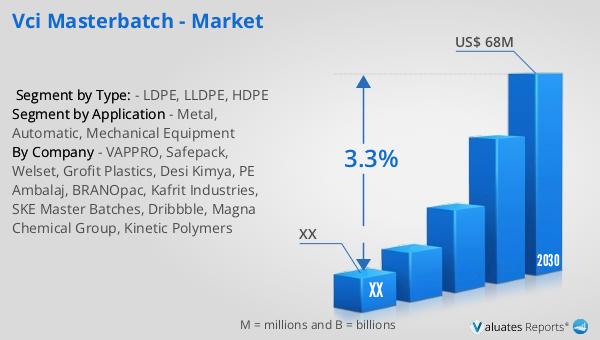

VCI Masterbatch - Global Market Outlook:

The global market for VCI Masterbatch was valued at approximately $34 million in 2023, and it is projected to grow to around $68 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for effective corrosion protection solutions across various industries. The North American market for VCI Masterbatch also shows promising growth potential, although specific figures for its valuation in 2023 and projected size by 2030 are not provided. The anticipated growth in this region is driven by the expanding industrial sector and the need for advanced packaging solutions that ensure the longevity and integrity of metal products. As industries continue to evolve and expand, the demand for VCI Masterbatch is expected to rise, driven by the need for reliable and efficient corrosion protection solutions. The market's growth is further supported by continuous innovation and development in VCI technology, with manufacturers focusing on enhancing the effectiveness and environmental sustainability of their products. This positive market outlook highlights the importance of VCI Masterbatch in protecting valuable metal components and products, ensuring their quality and performance throughout their lifecycle.

| Report Metric | Details |

| Report Name | VCI Masterbatch - Market |

| Forecasted market size in 2030 | US$ 68 million |

| CAGR | 3.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | VAPPRO, Safepack, Welset, Grofit Plastics, Desi Kimya, PE Ambalaj, BRANOpac, Kafrit Industries, SKE Master Batches, Dribbble, Magna Chemical Group, Kinetic Polymers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |