What is Global Electric Hot Water Generators Market?

The Global Electric Hot Water Generators Market refers to the worldwide industry involved in the production, distribution, and sale of electric hot water generators. These devices are essential for heating water using electrical energy, and they are widely used in residential, commercial, and industrial settings. The market encompasses various types of electric hot water generators, including tankless and storage models, each designed to meet specific needs and preferences. The demand for these generators is driven by factors such as the increasing need for energy-efficient heating solutions, the growing awareness of environmental sustainability, and the rising adoption of smart home technologies. Additionally, advancements in technology have led to the development of more efficient and reliable electric hot water generators, further boosting their popularity. The market is characterized by a diverse range of products offered by numerous manufacturers, each competing to provide the best combination of performance, efficiency, and cost-effectiveness. As a result, consumers have access to a wide variety of options to choose from, ensuring that they can find a solution that meets their specific requirements.

Electric, Solar, Gas in the Global Electric Hot Water Generators Market:

Electric hot water generators, solar hot water generators, and gas-based hot water generators each play a significant role in the Global Electric Hot Water Generators Market. Electric hot water generators are popular due to their ease of installation, low maintenance requirements, and ability to provide consistent hot water on demand. They are particularly favored in regions with a stable and affordable electricity supply. These generators come in various sizes and capacities, making them suitable for both small households and large industrial applications. On the other hand, solar hot water generators harness the power of the sun to heat water, making them an environmentally friendly and cost-effective option in the long run. They are especially beneficial in sunny regions where solar energy is abundant. Solar hot water generators typically consist of solar collectors, a storage tank, and a circulation system to transfer the heated water. While the initial investment for solar systems can be higher, the savings on energy bills and the positive environmental impact make them an attractive choice for eco-conscious consumers. Gas-based hot water generators, meanwhile, use natural gas or propane as a fuel source to heat water. These generators are known for their high efficiency and ability to provide hot water quickly. They are often used in areas where gas is readily available and can be a more economical option compared to electric models, especially in regions with high electricity costs. Gas-based generators can be either tankless or storage types, with tankless models offering the advantage of providing hot water on demand without the need for a storage tank. Each type of hot water generator has its own set of advantages and limitations, and the choice between them often depends on factors such as energy availability, cost considerations, and environmental impact. As the market continues to evolve, advancements in technology and increasing awareness of sustainability are likely to drive further innovation and adoption of these diverse hot water heating solutions.

Health Care, Process Steam and Heat, Wastewater Treatment in the Global Electric Hot Water Generators Market:

The Global Electric Hot Water Generators Market finds extensive usage in various sectors, including healthcare, process steam and heat, and wastewater treatment. In the healthcare sector, electric hot water generators are crucial for maintaining hygiene and ensuring the availability of hot water for various medical procedures and cleaning purposes. Hospitals, clinics, and other healthcare facilities rely on these generators to provide a consistent supply of hot water for sterilizing equipment, washing hands, and maintaining overall cleanliness. The reliability and efficiency of electric hot water generators make them an ideal choice for healthcare settings where uninterrupted hot water supply is essential. In the process steam and heat sector, electric hot water generators play a vital role in providing the necessary heat for various industrial processes. Industries such as food and beverage, pharmaceuticals, and chemical manufacturing require precise temperature control and consistent heat supply for their operations. Electric hot water generators offer a reliable and efficient solution for generating the required heat and steam, ensuring smooth and efficient production processes. Their ability to provide on-demand hot water and steam makes them a valuable asset in these industries. In the wastewater treatment sector, electric hot water generators are used to maintain the required temperature for various treatment processes. Heating the wastewater is essential for optimizing the efficiency of biological treatment processes, such as anaerobic digestion and activated sludge systems. Electric hot water generators provide a controlled and consistent heat source, ensuring that the treatment processes operate at their optimal conditions. This helps in improving the overall efficiency of the wastewater treatment plant and ensures compliance with environmental regulations. The versatility and efficiency of electric hot water generators make them an indispensable tool in these critical sectors, contributing to improved operational efficiency and sustainability.

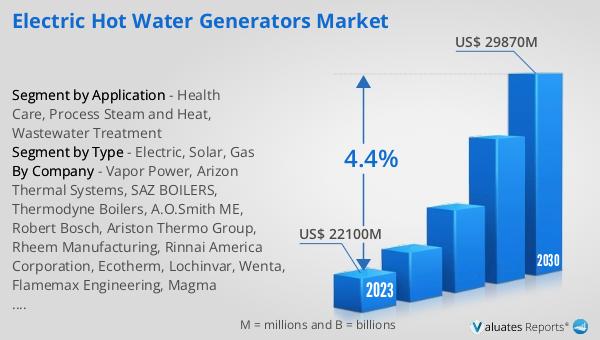

Global Electric Hot Water Generators Market Outlook:

The global Electric Hot Water Generators market was valued at US$ 22,100 million in 2023 and is anticipated to reach US$ 29,870 million by 2030, witnessing a CAGR of 4.4% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing demand for energy-efficient and reliable hot water solutions across various sectors. The rising awareness of environmental sustainability and the adoption of advanced technologies are key factors contributing to this growth. As consumers and industries alike seek more efficient and eco-friendly heating solutions, the market for electric hot water generators is expected to expand significantly. The projected growth also reflects the ongoing advancements in product design and functionality, which are enhancing the performance and appeal of electric hot water generators. With a diverse range of products available, from residential units to large-scale industrial systems, the market is well-positioned to cater to the evolving needs of different end-users. The anticipated increase in market value underscores the importance of electric hot water generators in meeting the global demand for efficient and sustainable heating solutions.

| Report Metric | Details |

| Report Name | Electric Hot Water Generators Market |

| Accounted market size in 2023 | US$ 22100 million |

| Forecasted market size in 2030 | US$ 29870 million |

| CAGR | 4.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vapor Power, Arizon Thermal Systems, SAZ BOILERS, Thermodyne Boilers, A.O.Smith ME, Robert Bosch, Ariston Thermo Group, Rheem Manufacturing, Rinnai America Corporation, Ecotherm, Lochinvar, Wenta, Flamemax Engineering, Magma Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |