What is Global Industrial Deaerators Market?

The Global Industrial Deaerators Market refers to the worldwide industry focused on the production and sale of deaerators, which are specialized devices used to remove dissolved gases, particularly oxygen and carbon dioxide, from water. These gases can cause corrosion and other issues in industrial systems, so their removal is crucial for maintaining the efficiency and longevity of equipment. Deaerators are commonly used in various industries, including power generation, chemical processing, food and beverage production, and paper manufacturing. The market encompasses a range of products, from small, portable units to large, complex systems designed for industrial-scale operations. The demand for deaerators is driven by the need for high-quality water in industrial processes, as well as stringent regulations regarding water treatment and environmental protection. As industries continue to expand and modernize, the Global Industrial Deaerators Market is expected to grow, offering numerous opportunities for manufacturers and suppliers.

Spray Type, Tray Type, Vacuum Type in the Global Industrial Deaerators Market:

In the Global Industrial Deaerators Market, there are several types of deaerators, each designed to meet specific needs and applications. The Spray Type deaerator is one of the most common and widely used. It operates by spraying water into a steam environment, where the heat causes the dissolved gases to be released and vented out. This type is highly efficient and is often used in power plants and other large-scale industrial operations. The Tray Type deaerator, on the other hand, uses a series of trays to increase the surface area of the water, allowing for more effective gas removal. Water flows over these trays, and steam is introduced to strip away the dissolved gases. This type is particularly effective in applications where high levels of gas removal are required. The Vacuum Type deaerator operates differently from the other two types. Instead of using steam, it creates a vacuum to lower the boiling point of water, causing the dissolved gases to be released. This type is often used in situations where steam is not readily available or where energy efficiency is a primary concern. Each of these types has its own advantages and disadvantages, and the choice of which to use depends on the specific requirements of the application. For example, Spray Type deaerators are known for their simplicity and reliability, making them a popular choice for many industries. Tray Type deaerators, with their high efficiency, are often used in applications where the highest levels of gas removal are necessary. Vacuum Type deaerators, with their energy efficiency, are ideal for applications where minimizing energy consumption is a priority. The Global Industrial Deaerators Market offers a wide range of options to meet the diverse needs of different industries, ensuring that there is a suitable solution for every application.

Chemical, Food, Papermaking, Generate Electricity, Other in the Global Industrial Deaerators Market:

The Global Industrial Deaerators Market finds extensive usage across various industries, each with its own unique requirements and challenges. In the chemical industry, deaerators are essential for ensuring the purity of water used in chemical reactions and processes. The presence of dissolved gases can lead to unwanted side reactions and corrosion, which can compromise the quality of the final product and the integrity of the equipment. By removing these gases, deaerators help maintain the efficiency and safety of chemical processes. In the food and beverage industry, deaerators play a crucial role in maintaining the quality and safety of products. Dissolved gases can affect the taste, appearance, and shelf life of food and beverages, so their removal is essential for ensuring product quality. Deaerators are used in various stages of food and beverage production, from water treatment to the preparation of ingredients and the final packaging of products. In the papermaking industry, deaerators are used to remove dissolved gases from the water used in the papermaking process. This helps prevent the formation of bubbles and other defects in the paper, ensuring a smooth and high-quality final product. Deaerators also help protect the equipment used in the papermaking process from corrosion and other damage caused by dissolved gases. In the power generation industry, deaerators are used to remove dissolved gases from the water used in boilers and other equipment. This helps prevent corrosion and other issues that can reduce the efficiency and lifespan of the equipment. Deaerators are an essential component of power plants, helping to ensure the reliable and efficient operation of the plant. In addition to these industries, deaerators are also used in various other applications, such as in the production of pharmaceuticals, the treatment of wastewater, and the manufacturing of various industrial products. The Global Industrial Deaerators Market offers a wide range of solutions to meet the diverse needs of different industries, ensuring that there is a suitable deaerator for every application.

Global Industrial Deaerators Market Outlook:

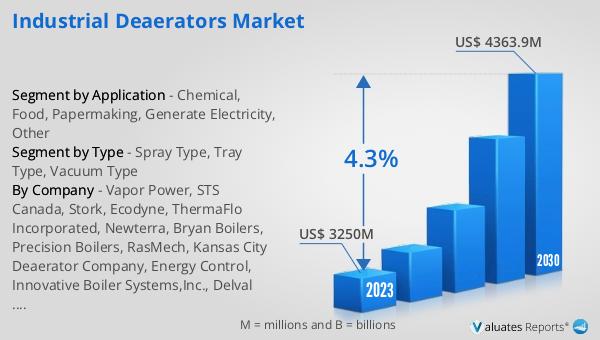

The global Industrial Deaerators market was valued at US$ 3250 million in 2023 and is anticipated to reach US$ 4363.9 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This growth reflects the increasing demand for high-quality water in various industrial processes and the need for efficient water treatment solutions. The market's expansion is driven by the ongoing modernization and expansion of industries, as well as stringent regulations regarding water treatment and environmental protection. As industries continue to evolve and adopt new technologies, the demand for advanced deaerators is expected to rise, offering numerous opportunities for manufacturers and suppliers in the Global Industrial Deaerators Market. The market's growth is also supported by the increasing awareness of the importance of water quality in industrial processes and the need to protect equipment from corrosion and other damage caused by dissolved gases. With the continuous development of new and innovative deaerator technologies, the Global Industrial Deaerators Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Industrial Deaerators Market |

| Accounted market size in 2023 | US$ 3250 million |

| Forecasted market size in 2030 | US$ 4363.9 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vapor Power, STS Canada, Stork, Ecodyne, ThermaFlo Incorporated, Newterra, Bryan Boilers, Precision Boilers, RasMech, Kansas City Deaerator Company, Energy Control, Innovative Boiler Systems,Inc., Delval Equipment, Industrial Steam, American Water Chemicals,Inc., Sterling Deaerator Company, MACH Engineering, Shipco Pumps, ATTSU TERMICA SL, Cleaver-Brooks, EN-FAB, Äager |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |