What is Global Boiler Deaerators Market?

The Global Boiler Deaerators Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to remove dissolved gases, particularly oxygen and carbon dioxide, from boiler feedwater. These gases, if not removed, can cause significant corrosion and damage to the boiler system, leading to inefficiencies and potential failures. Boiler deaerators are essential in maintaining the longevity and efficiency of boiler systems, which are critical components in various industries such as power generation, chemical processing, and manufacturing. The market for boiler deaerators is driven by the increasing demand for energy-efficient solutions and the need to comply with stringent environmental regulations. Additionally, advancements in technology have led to the development of more efficient and reliable deaerators, further propelling market growth. The global market is characterized by a mix of established players and new entrants, all striving to offer innovative solutions to meet the evolving needs of their customers.

Spray Type, Tray Type, Vacuum Type in the Global Boiler Deaerators Market:

In the Global Boiler Deaerators Market, there are several types of deaerators, each designed to meet specific operational requirements and efficiency standards. The Spray Type deaerator is one of the most common types and operates by spraying the feedwater into a steam atmosphere, which helps to remove dissolved gases. This type is highly efficient and is often used in industries where high purity and low oxygen levels are critical. The Tray Type deaerator, on the other hand, uses a series of trays to increase the surface area of the water, allowing for more effective gas removal. This type is particularly useful in applications where large volumes of water need to be treated quickly and efficiently. The Vacuum Type deaerator operates by creating a vacuum environment, which lowers the boiling point of water and allows for the removal of dissolved gases at lower temperatures. This type is ideal for applications where energy efficiency is a priority, as it requires less steam to operate. Each of these types has its own set of advantages and is chosen based on the specific needs of the application, such as the required level of gas removal, the volume of water to be treated, and the overall efficiency of the system.

Chemical, Food, Papermaking, Generate Electricity, Other in the Global Boiler Deaerators Market:

The usage of Global Boiler Deaerators Market spans across various industries, each with its unique requirements and challenges. In the chemical industry, boiler deaerators are crucial for maintaining the purity of feedwater, which is essential for the production of high-quality chemicals. The presence of dissolved gases can lead to corrosion and contamination, affecting the quality of the final product. In the food industry, boiler deaerators play a vital role in ensuring the safety and quality of food products. The removal of dissolved gases helps to prevent contamination and maintain the integrity of the production process. In the papermaking industry, boiler deaerators are used to ensure the quality of the steam used in the production process. The presence of dissolved gases can lead to defects in the final product, making deaerators an essential component of the production process. In the power generation industry, boiler deaerators are critical for maintaining the efficiency and longevity of boiler systems. The removal of dissolved gases helps to prevent corrosion and scaling, which can lead to significant operational issues and downtime. Other industries, such as pharmaceuticals and textiles, also rely on boiler deaerators to ensure the quality and efficiency of their production processes. Each of these industries has specific requirements and challenges, making the choice of the right type of deaerator crucial for maintaining operational efficiency and product quality.

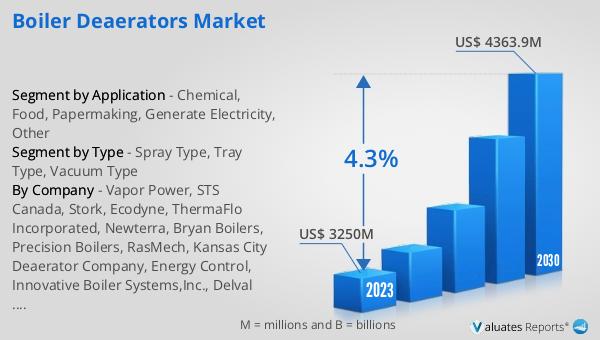

Global Boiler Deaerators Market Outlook:

The global Boiler Deaerators market was valued at US$ 3250 million in 2023 and is anticipated to reach US$ 4363.9 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This growth is driven by the increasing demand for energy-efficient solutions and the need to comply with stringent environmental regulations. The market is characterized by a mix of established players and new entrants, all striving to offer innovative solutions to meet the evolving needs of their customers. The advancements in technology have led to the development of more efficient and reliable deaerators, further propelling market growth. The market outlook indicates a positive trend, with significant opportunities for growth and innovation in the coming years. The increasing focus on sustainability and energy efficiency is expected to drive the demand for advanced boiler deaerators, making it a promising market for both existing players and new entrants.

| Report Metric | Details |

| Report Name | Boiler Deaerators Market |

| Accounted market size in 2023 | US$ 3250 million |

| Forecasted market size in 2030 | US$ 4363.9 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vapor Power, STS Canada, Stork, Ecodyne, ThermaFlo Incorporated, Newterra, Bryan Boilers, Precision Boilers, RasMech, Kansas City Deaerator Company, Energy Control, Innovative Boiler Systems,Inc., Delval Equipment, Industrial Steam, American Water Chemicals,Inc., Sterling Deaerator Company, MACH Engineering, Shipco Pumps, ATTSU TERMICA SL, Cleaver-Brooks, EN-FAB, Äager |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |