What is Global Spray Deaerator Market?

The Global Spray Deaerator Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to remove dissolved gases, primarily oxygen and carbon dioxide, from liquids. These devices are crucial in various industries to prevent corrosion, improve efficiency, and ensure the longevity of equipment. The market encompasses a range of products, including vertical and horizontal spray deaerators, each tailored to specific applications and operational requirements. The demand for spray deaerators is driven by their essential role in maintaining the quality and performance of industrial processes, particularly in sectors like power generation, chemical manufacturing, food processing, and papermaking. As industries continue to prioritize efficiency and equipment longevity, the global spray deaerator market is expected to see sustained growth. The market's expansion is also influenced by technological advancements and the increasing adoption of automation in industrial processes, which enhance the effectiveness and reliability of deaeration systems. Overall, the global spray deaerator market is a vital component of the industrial landscape, contributing to the smooth and efficient operation of various critical processes.

Vertical Spray Deaerator, Horizontal Spray Deaerator in the Global Spray Deaerator Market:

Vertical spray deaerators and horizontal spray deaerators are two primary types of deaeration systems used in the global spray deaerator market. Vertical spray deaerators are designed with a vertical orientation, making them suitable for installations where space is limited. These systems typically consist of a vertical tank with a spray nozzle at the top, which distributes the incoming water in fine droplets. As the water droplets fall through the tank, they come into contact with steam, which heats the water and removes dissolved gases. The vertical design allows for efficient deaeration in a compact footprint, making it ideal for facilities with height constraints. On the other hand, horizontal spray deaerators are designed with a horizontal orientation, providing a larger surface area for the water to come into contact with steam. This design is particularly effective in applications where high flow rates are required, as the horizontal configuration allows for greater water volume to be processed simultaneously. Horizontal spray deaerators typically consist of a horizontal tank with multiple spray nozzles, ensuring even distribution of water and efficient gas removal. Both vertical and horizontal spray deaerators play a crucial role in various industries, ensuring the removal of dissolved gases to prevent corrosion and improve the efficiency of industrial processes. The choice between vertical and horizontal spray deaerators depends on factors such as available space, flow rate requirements, and specific application needs. In summary, vertical spray deaerators are compact and efficient for installations with limited space, while horizontal spray deaerators offer higher capacity and are suitable for applications with high flow rates. Both types are essential components of the global spray deaerator market, catering to the diverse needs of industries that rely on effective deaeration to maintain the quality and performance of their processes.

Chemical, Food, Papermaking, Generate Electricity, Other in the Global Spray Deaerator Market:

The global spray deaerator market finds extensive usage across various industries, including chemical, food, papermaking, power generation, and others. In the chemical industry, spray deaerators are essential for removing dissolved gases from process water and feedwater, which is crucial for preventing corrosion in chemical reactors and pipelines. By ensuring the purity of water used in chemical processes, spray deaerators help maintain the integrity and efficiency of chemical production. In the food industry, spray deaerators play a vital role in ensuring the quality and safety of food products. They are used to remove dissolved gases from water used in food processing, which helps prevent oxidation and spoilage of food products. This is particularly important in the production of beverages, canned foods, and dairy products, where maintaining product quality is paramount. In the papermaking industry, spray deaerators are used to remove dissolved gases from process water, which is essential for preventing corrosion in paper mills and ensuring the quality of paper products. By removing oxygen and carbon dioxide from water, spray deaerators help maintain the efficiency and longevity of papermaking equipment. In the power generation industry, spray deaerators are critical for maintaining the efficiency and reliability of power plants. They are used to remove dissolved gases from boiler feedwater, which helps prevent corrosion in boilers and steam turbines. This is essential for ensuring the safe and efficient operation of power plants, as well as extending the lifespan of critical equipment. Additionally, spray deaerators are used in various other industries, such as pharmaceuticals, oil and gas, and water treatment, where the removal of dissolved gases is crucial for maintaining process efficiency and equipment longevity. Overall, the global spray deaerator market plays a vital role in ensuring the quality and efficiency of industrial processes across a wide range of industries, contributing to the smooth and reliable operation of critical equipment and systems.

Global Spray Deaerator Market Outlook:

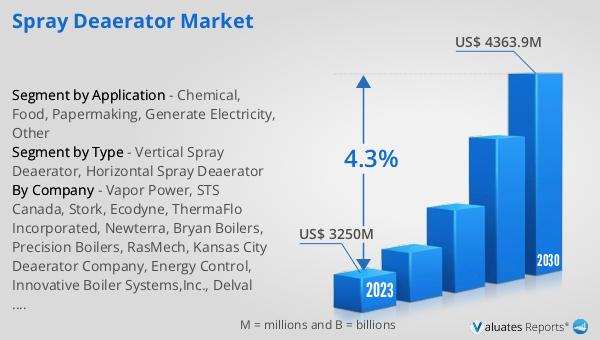

The global spray deaerator market was valued at US$ 3250 million in 2023 and is anticipated to reach US$ 4363.9 million by 2030, witnessing a CAGR of 4.3% during the forecast period 2024-2030. This growth reflects the increasing demand for efficient and reliable deaeration systems across various industries. The market's expansion is driven by the need to prevent corrosion, improve process efficiency, and extend the lifespan of industrial equipment. As industries continue to prioritize operational efficiency and equipment longevity, the demand for spray deaerators is expected to rise. Technological advancements and the adoption of automation in industrial processes are also contributing to the market's growth, enhancing the effectiveness and reliability of deaeration systems. Overall, the global spray deaerator market is poised for steady growth, driven by the essential role of deaeration in maintaining the quality and performance of industrial processes.

| Report Metric | Details |

| Report Name | Spray Deaerator Market |

| Accounted market size in 2023 | US$ 3250 million |

| Forecasted market size in 2030 | US$ 4363.9 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vapor Power, STS Canada, Stork, Ecodyne, ThermaFlo Incorporated, Newterra, Bryan Boilers, Precision Boilers, RasMech, Kansas City Deaerator Company, Energy Control, Innovative Boiler Systems,Inc., Delval Equipment, Industrial Steam, American Water Chemicals,Inc., Sterling Deaerator Company, MACH Engineering, Shipco Pumps, ATTSU TERMICA SL, Cleaver-Brooks, EN-FAB, Äager |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |