What is Global Chilled Warehouse Automation (0–10°C) Market?

The Global Chilled Warehouse Automation (0–10°C) Market refers to the technological advancements and systems designed to enhance the efficiency and effectiveness of warehouses that store goods at chilled temperatures, typically between 0 to 10 degrees Celsius. These warehouses are crucial for preserving the quality and safety of perishable goods such as food, beverages, and pharmaceuticals. Automation in this context involves the use of advanced technologies like robotics, automated storage and retrieval systems (AS/RS), and conveyor systems to streamline operations, reduce human error, and increase throughput. The market for these automated solutions is driven by the growing demand for fresh and frozen products, the need for efficient supply chain management, and the increasing adoption of technology in logistics. As businesses strive to meet consumer expectations for faster delivery and fresher products, the adoption of chilled warehouse automation is becoming increasingly essential. This market is characterized by continuous innovation, with companies investing in new technologies to improve energy efficiency, reduce operational costs, and enhance the overall performance of their warehouse operations.

AS/RS Automated Storage & Retrieval System, Shuttle-Based Storage System, AGV/AMR Handling System, Conveyor & Sorting System, Robotic Palletizing System in the Global Chilled Warehouse Automation (0–10°C) Market:

Automated Storage and Retrieval Systems (AS/RS) are a cornerstone of the Global Chilled Warehouse Automation market, designed to optimize the storage and retrieval of goods in chilled environments. These systems use computer-controlled systems to automatically place and retrieve loads from defined storage locations, significantly reducing the need for manual labor and minimizing human error. AS/RS systems are particularly beneficial in chilled warehouses where maintaining a consistent temperature is crucial, as they reduce the time that goods spend outside of their optimal storage conditions. Shuttle-Based Storage Systems are another key component, offering high-density storage solutions that maximize space utilization. These systems use shuttles to move goods within the storage area, allowing for rapid and efficient retrieval. They are ideal for chilled environments where space is at a premium and quick access to goods is essential. AGV (Automated Guided Vehicles) and AMR (Autonomous Mobile Robots) Handling Systems are also integral to chilled warehouse automation. These systems transport goods within the warehouse without the need for human intervention, using sensors and navigation systems to move safely and efficiently. They are particularly useful in chilled environments where reducing human exposure to cold temperatures is a priority. Conveyor and Sorting Systems play a crucial role in the movement and organization of goods within chilled warehouses. These systems automate the process of moving goods from one area to another, ensuring that products are sorted and directed to the correct location quickly and accurately. This is essential in chilled environments where maintaining the integrity of the cold chain is critical. Robotic Palletizing Systems are used to automate the process of stacking and organizing products onto pallets. These systems use robotic arms to handle goods, reducing the need for manual labor and increasing the speed and accuracy of the palletizing process. In chilled warehouses, robotic palletizing systems help maintain product quality by minimizing the time that goods spend outside of their optimal storage conditions. Overall, these automated systems work together to create a seamless and efficient operation within chilled warehouses, ensuring that goods are stored, retrieved, and transported in a manner that maintains their quality and safety.

Food & Beverage Warehouses, Cold Chain Logistics Centers, Supermarkets & Retail Distribution Centers, Pharmaceutical Cold Storage, E-commerce Fresh Distribution, Others in the Global Chilled Warehouse Automation (0–10°C) Market:

The usage of Global Chilled Warehouse Automation (0–10°C) Market spans several critical areas, each benefiting from the enhanced efficiency and reliability that automation brings. In Food & Beverage Warehouses, automation ensures that perishable goods are stored and retrieved quickly, maintaining their freshness and quality. Automated systems reduce the time products spend outside of their optimal temperature range, minimizing spoilage and waste. Cold Chain Logistics Centers rely on automation to maintain the integrity of the cold chain, ensuring that products are kept at the correct temperature throughout the storage and transportation process. This is crucial for products like dairy, meat, and seafood, where temperature fluctuations can lead to spoilage and health risks. Supermarkets & Retail Distribution Centers use chilled warehouse automation to manage inventory more effectively, ensuring that products are available when needed and reducing the risk of stockouts. Automation also helps these centers respond quickly to changes in demand, ensuring that fresh products are always available to consumers. Pharmaceutical Cold Storage facilities benefit from automation by ensuring that temperature-sensitive medications and vaccines are stored under optimal conditions. Automated systems help maintain the precise temperature controls required for these products, reducing the risk of degradation and ensuring their efficacy. E-commerce Fresh Distribution centers use automation to manage the rapid turnover of fresh products, ensuring that orders are fulfilled quickly and accurately. Automation helps these centers handle the high volume of orders typical in e-commerce, reducing the risk of errors and ensuring that products are delivered to consumers in the best possible condition. Other areas, such as floral distribution and specialty food storage, also benefit from chilled warehouse automation, as these systems help maintain the quality and freshness of products that are sensitive to temperature changes. Overall, the use of automation in chilled warehouses enhances the efficiency, reliability, and safety of operations across a wide range of industries, ensuring that products are stored and transported in a manner that maintains their quality and safety.

Global Chilled Warehouse Automation (0–10°C) Market Outlook:

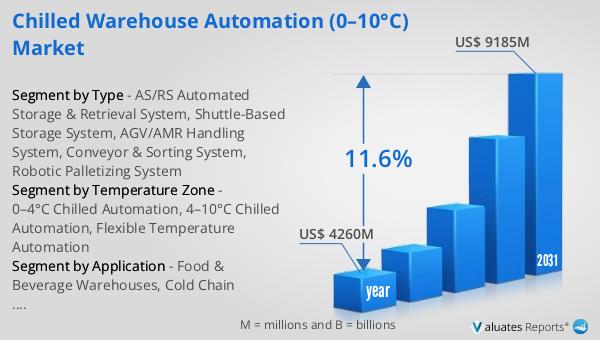

The global market for Chilled Warehouse Automation (0–10°C) was valued at approximately $4.26 billion in 2024. This market is anticipated to expand significantly, reaching an estimated size of $9.185 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 11.6% over the forecast period. The increasing demand for efficient and reliable storage solutions for temperature-sensitive goods is a key driver of this market growth. As consumer expectations for fresh and high-quality products continue to rise, businesses are investing in advanced automation technologies to enhance their warehouse operations. The adoption of automated systems in chilled warehouses helps companies reduce operational costs, improve energy efficiency, and increase throughput, all of which contribute to the overall growth of the market. Additionally, the need for effective supply chain management and the growing importance of maintaining the integrity of the cold chain are further fueling the demand for chilled warehouse automation solutions. As a result, the market is expected to continue its upward trajectory, driven by technological advancements and the increasing adoption of automation across various industries.

| Report Metric | Details |

| Report Name | Chilled Warehouse Automation (0–10°C) Market |

| Accounted market size in year | US$ 4260 million |

| Forecasted market size in 2031 | US$ 9185 million |

| CAGR | 11.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by System Type |

|

| Segment by Temperature Zone |

|

| Segment by Application |

|

| By Region |

|

| By Company | SSI SCHAEFER, Daifuku, Dematic, Honeywell Intelligrated, Swisslog, Ocado Group, Kardex, Murata Machinery, TGW Logistics Group, Mecalux, Vanderlande, Bastian Solutions |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |