What is Global Automatic Non-Contact Extensometer Market?

The Global Automatic Non-Contact Extensometer Market is a specialized segment within the broader field of material testing and measurement. Extensometers are devices used to measure the change in length of an object under stress, which is crucial for understanding material properties such as elasticity, tensile strength, and deformation. The "non-contact" aspect refers to the technology's ability to measure these changes without physically touching the material, which is particularly useful for delicate or high-temperature materials that could be damaged by traditional contact methods. Automatic non-contact extensometers utilize advanced technologies like laser, video, and digital image correlation to provide precise and accurate measurements. These devices are widely used in industries such as aerospace, automotive, construction, and manufacturing, where understanding material behavior under stress is critical for safety and performance. The market for these devices is growing due to the increasing demand for high-precision testing and the need for more efficient and reliable measurement techniques.

in the Global Automatic Non-Contact Extensometer Market:

The Global Automatic Non-Contact Extensometer Market offers a variety of types to cater to the diverse needs of its customers. One of the most common types is the laser extensometer, which uses laser beams to measure the distance between two points on a material. This type is highly accurate and can be used in a wide range of applications, from testing metals to polymers. Another popular type is the video extensometer, which employs high-resolution cameras to capture the deformation of a material. This type is particularly useful for materials that are difficult to measure with traditional methods, such as soft or transparent materials. Digital Image Correlation (DIC) extensometers are another advanced type, using sophisticated software to analyze images and calculate strain and deformation. These are highly versatile and can be used in complex testing scenarios, including multi-axial testing. Additionally, there are infrared extensometers that are designed for high-temperature applications. These use infrared technology to measure changes in length without being affected by the heat, making them ideal for testing materials in furnaces or other high-temperature environments. Each of these types has its own set of advantages and limitations, and the choice of extensometer often depends on the specific requirements of the testing application. For instance, laser extensometers are known for their high accuracy and speed, making them suitable for dynamic testing where rapid measurements are needed. On the other hand, video extensometers are preferred for their ability to measure large deformations and their non-intrusive nature, which is crucial for testing delicate materials. Digital Image Correlation extensometers offer the advantage of providing full-field strain measurements, which can be invaluable for understanding complex material behaviors. Infrared extensometers, with their ability to operate in high-temperature environments, are indispensable for industries like aerospace and automotive, where materials are often subjected to extreme conditions. The market also includes hybrid extensometers that combine multiple technologies to offer enhanced capabilities. For example, some devices integrate both laser and video technologies to provide the benefits of both methods, offering high accuracy and the ability to measure large deformations. These hybrid systems are particularly useful in research and development settings, where a wide range of testing scenarios may be encountered. The choice of extensometer is also influenced by factors such as cost, ease of use, and maintenance requirements. While laser and video extensometers are generally more expensive due to their advanced technology, they offer significant benefits in terms of accuracy and versatility. Digital Image Correlation systems, although complex, provide comprehensive data that can be crucial for advanced material analysis. Infrared extensometers, while specialized, are essential for certain high-temperature applications and offer unique advantages that cannot be matched by other types. In summary, the Global Automatic Non-Contact Extensometer Market offers a wide range of types to meet the diverse needs of its customers. Each type has its own set of advantages and is suited to specific applications, making it important for users to carefully consider their requirements when selecting an extensometer.

in the Global Automatic Non-Contact Extensometer Market:

The Global Automatic Non-Contact Extensometer Market finds applications across a wide range of industries, each with its own unique requirements and challenges. In the aerospace industry, these devices are used to test the mechanical properties of materials used in aircraft and spacecraft. The ability to measure strain and deformation without physical contact is particularly important in this industry, where materials are often lightweight and delicate. Automatic non-contact extensometers help ensure that these materials can withstand the extreme conditions they will encounter in service, such as high speeds, temperatures, and pressures. In the automotive industry, these devices are used to test the strength and durability of materials used in vehicles. This includes everything from the metals used in the chassis to the polymers used in interior components. The ability to accurately measure how these materials behave under stress is crucial for ensuring the safety and performance of vehicles. In the construction industry, automatic non-contact extensometers are used to test the properties of building materials such as concrete, steel, and composites. These materials must meet stringent standards to ensure the safety and durability of structures, and non-contact extensometers provide the precise measurements needed to verify their performance. In the manufacturing industry, these devices are used to test a wide range of materials and components. This includes everything from the metals used in machinery to the plastics used in consumer products. The ability to measure strain and deformation without physical contact is particularly useful in this industry, where materials can vary widely in terms of size, shape, and properties. In the research and development sector, automatic non-contact extensometers are used to study the behavior of new materials and to develop new testing methods. These devices provide the high-precision measurements needed to understand the complex behaviors of advanced materials, such as composites and nanomaterials. They are also used to develop new testing standards and protocols, helping to advance the field of material science. In the energy sector, these devices are used to test the properties of materials used in power generation and distribution. This includes everything from the metals used in turbines to the polymers used in insulation. The ability to accurately measure how these materials behave under stress is crucial for ensuring the reliability and efficiency of energy systems. In the medical industry, automatic non-contact extensometers are used to test the properties of materials used in medical devices and implants. This includes everything from the metals used in surgical instruments to the polymers used in prosthetics. The ability to measure strain and deformation without physical contact is particularly important in this industry, where materials must meet stringent standards for safety and biocompatibility. In the electronics industry, these devices are used to test the properties of materials used in electronic components and devices. This includes everything from the metals used in circuit boards to the polymers used in casings. The ability to accurately measure how these materials behave under stress is crucial for ensuring the performance and reliability of electronic devices. In summary, the Global Automatic Non-Contact Extensometer Market finds applications across a wide range of industries, each with its own unique requirements and challenges. These devices provide the high-precision measurements needed to ensure the safety, performance, and reliability of materials and components used in a wide range of applications.

Global Automatic Non-Contact Extensometer Market Outlook:

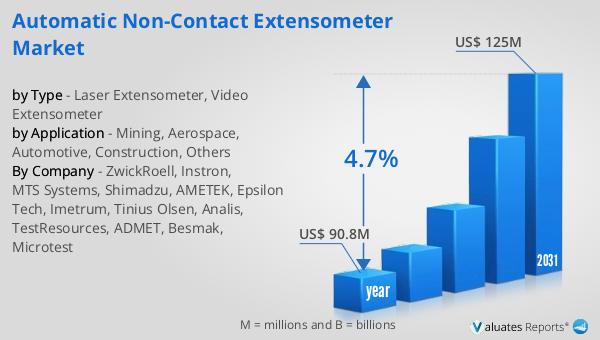

The global market for Automatic Non-Contact Extensometers was valued at $83 million in 2023 and is projected to grow to $114.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-precision testing and the need for more efficient and reliable measurement techniques across various industries. The market's expansion is also fueled by advancements in technology, which have made these devices more accurate, versatile, and user-friendly. As industries such as aerospace, automotive, construction, and manufacturing continue to evolve and require more sophisticated testing methods, the demand for automatic non-contact extensometers is expected to rise. These devices play a crucial role in ensuring the safety, performance, and reliability of materials and components, making them indispensable in modern material testing and measurement. The market's growth is also supported by the increasing focus on research and development, which drives the need for advanced testing equipment. As new materials and technologies are developed, the need for precise and accurate measurement tools becomes even more critical. Overall, the global market for Automatic Non-Contact Extensometers is poised for steady growth, driven by technological advancements and the increasing demand for high-precision testing across various industries.

| Report Metric | Details |

| Report Name | Automatic Non-Contact Extensometer Market |

| Accounted market size in 2023 | US$ 83 million |

| Forecasted market size in 2030 | US$ 114.7 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |