What is Global High-pressure Hydrogen Cylinder Valve Market?

The Global High-pressure Hydrogen Cylinder Valve Market is a specialized segment within the broader hydrogen economy, focusing on the development and distribution of valves designed to handle high-pressure hydrogen gas. These valves are critical components in hydrogen storage and transportation systems, ensuring the safe and efficient management of hydrogen gas under high pressure. As the world shifts towards cleaner energy sources, hydrogen is gaining prominence due to its potential as a sustainable and zero-emission fuel. High-pressure hydrogen cylinder valves are essential for various applications, including on-board hydrogen storage systems in vehicles, hydrogen refueling stations, and transport hydrogen storage systems. These valves must meet stringent safety and performance standards to prevent leaks and ensure the safe handling of hydrogen, which is highly flammable. The market for these valves is driven by the increasing adoption of hydrogen as an alternative energy source, advancements in hydrogen storage technologies, and the growing demand for hydrogen-powered vehicles. As countries invest in hydrogen infrastructure and technology, the demand for high-pressure hydrogen cylinder valves is expected to rise, making this market a crucial component of the global transition to sustainable energy.

35MPa Bottle-Mouth Valve, 70MPa Bottle-Mouth Valve, Others in the Global High-pressure Hydrogen Cylinder Valve Market:

The Global High-pressure Hydrogen Cylinder Valve Market includes various types of valves, each designed to meet specific pressure requirements and applications. Among these, the 35MPa Bottle-Mouth Valve is a common choice for applications requiring moderate pressure levels. These valves are typically used in hydrogen storage systems where the pressure does not exceed 35 megapascals (MPa). They are designed to provide a reliable seal and control the flow of hydrogen gas, ensuring safety and efficiency. The 35MPa valves are often used in smaller hydrogen storage systems and are suitable for applications where space and weight are considerations, such as in portable hydrogen storage units or smaller vehicles. On the other hand, the 70MPa Bottle-Mouth Valve is designed for high-pressure applications, capable of handling pressures up to 70 MPa. These valves are essential for larger hydrogen storage systems and are commonly used in hydrogen refueling stations and larger vehicles, such as buses and trucks, that require higher pressure for efficient hydrogen storage and delivery. The 70MPa valves are engineered to withstand the high pressures associated with these applications, providing a robust and reliable solution for managing hydrogen gas. In addition to the 35MPa and 70MPa valves, there are other types of valves in the market designed for specific applications and pressure requirements. These may include valves with specialized features, such as enhanced sealing mechanisms, corrosion-resistant materials, or integrated pressure relief systems. The choice of valve depends on various factors, including the specific application, pressure requirements, and environmental conditions. As the demand for hydrogen as a clean energy source continues to grow, the development and innovation of high-pressure hydrogen cylinder valves are expected to advance, offering more efficient and safer solutions for hydrogen storage and transportation.

On-Board Hydrogen Storage System, Hydrogen Refueling Station, Transport Hydrogen Storage System, Others in the Global High-pressure Hydrogen Cylinder Valve Market:

The Global High-pressure Hydrogen Cylinder Valve Market plays a vital role in various applications, including On-Board Hydrogen Storage Systems, Hydrogen Refueling Stations, Transport Hydrogen Storage Systems, and others. In On-Board Hydrogen Storage Systems, these valves are crucial for managing the storage and flow of hydrogen gas within vehicles. They ensure that hydrogen is safely stored at high pressures and can be efficiently delivered to the fuel cell or combustion engine as needed. The valves must be designed to withstand the dynamic conditions of vehicle operation, including vibrations, temperature fluctuations, and pressure changes. In Hydrogen Refueling Stations, high-pressure hydrogen cylinder valves are essential for controlling the flow of hydrogen during the refueling process. These valves must ensure a safe and efficient transfer of hydrogen from storage tanks to vehicles, preventing leaks and ensuring that the refueling process is quick and reliable. The valves used in refueling stations are typically designed to handle high pressures and are equipped with safety features to prevent over-pressurization and ensure the safety of both the station and the vehicles being refueled. Transport Hydrogen Storage Systems also rely on high-pressure hydrogen cylinder valves to manage the storage and transportation of hydrogen gas. These systems are used to transport hydrogen from production facilities to end-users, such as refueling stations or industrial sites. The valves in these systems must be robust and reliable, capable of maintaining a secure seal under high pressures and varying environmental conditions. They play a critical role in ensuring that hydrogen can be transported safely and efficiently over long distances. In addition to these applications, high-pressure hydrogen cylinder valves are used in various other settings, such as industrial hydrogen storage systems, research facilities, and emergency hydrogen supply systems. In each of these applications, the valves must meet stringent safety and performance standards to ensure the safe handling of hydrogen gas. As the hydrogen economy continues to expand, the demand for high-quality, reliable high-pressure hydrogen cylinder valves is expected to grow, driving innovation and development in this critical market segment.

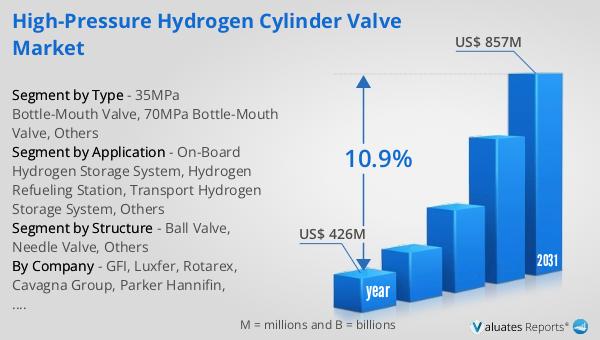

Global High-pressure Hydrogen Cylinder Valve Market Outlook:

The global market for High-pressure Hydrogen Cylinder Valves was valued at approximately $426 million in 2024. This market is anticipated to experience significant growth, reaching an estimated value of $857 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 10.9% over the forecast period. The increasing adoption of hydrogen as a clean energy source is a key driver of this market expansion. As countries and industries worldwide seek to reduce carbon emissions and transition to sustainable energy solutions, hydrogen is emerging as a viable alternative to fossil fuels. This shift is fueling the demand for high-pressure hydrogen cylinder valves, which are essential components in hydrogen storage and transportation systems. The market's growth is also supported by advancements in hydrogen storage technologies and the development of hydrogen infrastructure, such as refueling stations and transport systems. As these technologies and infrastructures continue to evolve, the demand for high-pressure hydrogen cylinder valves is expected to rise, further driving market growth. The projected growth of this market underscores the increasing importance of hydrogen in the global energy landscape and highlights the critical role that high-pressure hydrogen cylinder valves play in enabling the safe and efficient use of hydrogen as a clean energy source.

| Report Metric | Details |

| Report Name | High-pressure Hydrogen Cylinder Valve Market |

| Accounted market size in year | US$ 426 million |

| Forecasted market size in 2031 | US$ 857 million |

| CAGR | 10.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GFI, Luxfer, Rotarex, Cavagna Group, Parker Hannifin, Swagelok, WITT-Gasetechnik, Faber Industrie, NPROXX, OMB Saleri, WEH GmbH, Jiangsu Shentong Valve Co., Ltd, Zhangjiagang Furui Special Equipment Co., Ltd, QINVAL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |