What is Global Low Foaming Industrial Degreaser Market?

The Global Low Foaming Industrial Degreaser Market is a specialized segment within the broader industrial cleaning products industry. These degreasers are specifically formulated to remove grease, oil, dirt, and other contaminants from various surfaces without producing excessive foam. This characteristic is particularly important in industrial settings where high-pressure cleaning equipment is used, as excessive foam can interfere with the cleaning process and equipment operation. The market for these products is driven by the need for efficient and effective cleaning solutions in industries such as automotive, aerospace, marine, and manufacturing. The demand is further fueled by stringent environmental regulations that require the use of low-emission and biodegradable cleaning agents. Companies in this market are continuously innovating to develop products that not only meet these regulatory requirements but also deliver superior cleaning performance. As industries continue to expand globally, the need for reliable and efficient cleaning solutions like low foaming industrial degreasers is expected to grow, making this market an essential component of the industrial cleaning sector.

Alkaline Degreaser, Enzymatic Degreaser, Surfactant-only Degreaser in the Global Low Foaming Industrial Degreaser Market:

Alkaline degreasers, enzymatic degreasers, and surfactant-only degreasers are three key types of products within the Global Low Foaming Industrial Degreaser Market, each offering unique benefits and applications. Alkaline degreasers are formulated with alkaline chemicals, which are effective at breaking down organic materials such as oils and greases. These degreasers are particularly useful in heavy-duty cleaning applications where stubborn residues need to be removed. They work by saponifying fats and oils, turning them into soap and glycerin, which can then be easily rinsed away. Alkaline degreasers are commonly used in industries like automotive and industrial machinery, where heavy grease buildup is a frequent issue. However, they must be used with caution as they can be corrosive to certain materials and surfaces if not properly diluted or rinsed. Enzymatic degreasers, on the other hand, utilize natural enzymes to break down organic matter. These enzymes act as catalysts, speeding up the chemical reactions that decompose oils and greases into simpler, water-soluble substances. Enzymatic degreasers are often favored for their environmental friendliness and safety, as they typically contain fewer harsh chemicals compared to traditional degreasers. They are particularly effective in applications where a gentle yet thorough cleaning is required, such as in the food processing industry or in environments where human contact with cleaning agents is frequent. The use of enzymatic degreasers is growing as industries seek more sustainable and less toxic cleaning solutions. Surfactant-only degreasers rely on surfactants, which are compounds that lower the surface tension between two substances, such as a solid and a liquid. These degreasers work by emulsifying oils and greases, allowing them to be easily rinsed away with water. Surfactant-only degreasers are versatile and can be used in a wide range of applications, from light-duty cleaning tasks to more demanding industrial processes. They are particularly useful in situations where foaming needs to be minimized, as they can be formulated to produce little to no foam. This makes them ideal for use in high-pressure cleaning systems and automated washing equipment, where excessive foam can cause operational issues. Each type of degreaser has its own set of advantages and limitations, and the choice of which to use often depends on the specific cleaning requirements and environmental considerations of the application. For instance, while alkaline degreasers are highly effective for heavy-duty cleaning, they may not be suitable for all surfaces or environments due to their corrosive nature. Enzymatic degreasers offer a more environmentally friendly option but may require longer contact times to achieve the desired level of cleanliness. Surfactant-only degreasers provide a balance between cleaning power and safety, making them a popular choice for many industrial applications. As the Global Low Foaming Industrial Degreaser Market continues to evolve, manufacturers are likely to focus on developing products that combine the strengths of these different types of degreasers while minimizing their drawbacks. This ongoing innovation will be crucial in meeting the diverse needs of industries worldwide and ensuring compliance with increasingly stringent environmental regulations.

Automotive, Marine, Aerospace & Defense, Industrial Machinery, Others in the Global Low Foaming Industrial Degreaser Market:

The Global Low Foaming Industrial Degreaser Market finds extensive usage across various sectors, including automotive, marine, aerospace and defense, industrial machinery, and others. In the automotive industry, these degreasers are essential for maintaining the cleanliness and efficiency of vehicles. They are used to remove grease, oil, and other contaminants from engines, transmissions, and other mechanical components. The low foaming nature of these degreasers ensures that they do not interfere with the operation of high-pressure cleaning equipment, making them ideal for use in automotive workshops and manufacturing plants. Additionally, the use of environmentally friendly degreasers helps automotive companies comply with regulations aimed at reducing emissions and waste. In the marine industry, low foaming industrial degreasers are used to clean and maintain ships, boats, and other marine vessels. These degreasers are effective at removing the tough grime and salt deposits that accumulate on marine equipment and surfaces. The low foaming characteristic is particularly important in this sector, as excessive foam can pose a safety hazard on wet and slippery decks. Furthermore, the use of biodegradable and non-toxic degreasers is crucial in protecting marine ecosystems from pollution, aligning with the industry's growing focus on sustainability. The aerospace and defense sectors also rely heavily on low foaming industrial degreasers for the maintenance and cleaning of aircraft and military equipment. These degreasers are used to remove hydraulic fluids, oils, and other contaminants from aircraft engines, landing gear, and other critical components. The low foaming property ensures that cleaning processes are efficient and do not interfere with the sensitive equipment used in these industries. Moreover, the use of degreasers that meet strict environmental and safety standards is essential in these sectors, where compliance with regulations is of utmost importance. In the industrial machinery sector, low foaming industrial degreasers are used to clean and maintain a wide range of equipment and machinery. These degreasers help prevent the buildup of grease and grime, which can lead to equipment malfunctions and reduced efficiency. The low foaming nature of these products ensures that they can be used in high-pressure cleaning systems without causing operational issues. Additionally, the use of environmentally friendly degreasers helps companies in this sector meet sustainability goals and reduce their environmental impact. Beyond these specific industries, low foaming industrial degreasers are also used in various other applications, such as food processing, pharmaceuticals, and manufacturing. In these sectors, the need for effective and safe cleaning solutions is paramount, and low foaming degreasers offer a reliable option. As industries continue to prioritize sustainability and efficiency, the demand for low foaming industrial degreasers is expected to grow, driving innovation and development in this market.

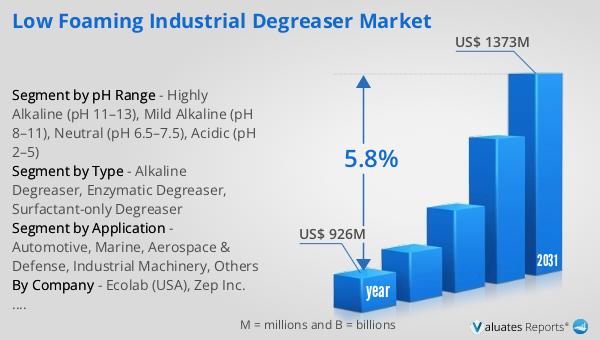

Global Low Foaming Industrial Degreaser Market Outlook:

The global market for Low Foaming Industrial Degreaser was valued at $926 million in 2024, and it is anticipated to expand to a revised size of $1,373 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% over the forecast period. This growth trajectory underscores the increasing demand for efficient and environmentally friendly cleaning solutions across various industries. The market's expansion is driven by several factors, including the rising awareness of the environmental impact of traditional cleaning agents and the subsequent shift towards more sustainable alternatives. Additionally, the stringent regulations imposed by governments worldwide to curb emissions and promote the use of biodegradable products are further propelling the market's growth. Industries such as automotive, aerospace, marine, and industrial machinery are increasingly adopting low foaming industrial degreasers due to their effectiveness in removing stubborn grease and grime without producing excessive foam. This characteristic is particularly important in high-pressure cleaning applications, where foam can hinder the cleaning process and affect equipment performance. Moreover, the development of innovative degreaser formulations that combine powerful cleaning capabilities with minimal environmental impact is attracting more industries to adopt these products. As the market continues to grow, manufacturers are focusing on research and development to create advanced degreasers that meet the evolving needs of industries while adhering to environmental standards. This ongoing innovation is expected to further drive the market's growth, making low foaming industrial degreasers an integral part of the industrial cleaning landscape.

| Report Metric | Details |

| Report Name | Low Foaming Industrial Degreaser Market |

| Accounted market size in year | US$ 926 million |

| Forecasted market size in 2031 | US$ 1373 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by pH Range |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ecolab (USA), Zep Inc. (USA), Diversey (USA), 3M Company (USA), Henkel (Germany), DuBois Chemicals (USA), Spartan Chemical (USA), Nyco Products (USA), Betco Corporation (USA), Hillyard (USA), Quaker Houghton (USA), Kersia Group (France), Clover Chemicals (Belgium), CP Industries (Canada), Solenis (USA), Rust-Oleum (USA) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |