What is Global Thermal Power Plant Control System Market?

The Global Thermal Power Plant Control System Market refers to the industry that focuses on the development, implementation, and maintenance of control systems specifically designed for thermal power plants. These systems are crucial for managing and optimizing the operations of power plants that generate electricity through the conversion of heat energy, typically from fossil fuels like coal, oil, and natural gas. The control systems ensure that the power plants operate efficiently, safely, and in compliance with environmental regulations. They monitor and control various processes within the plant, such as fuel handling, combustion, steam generation, and electricity production. By automating these processes, the control systems help in reducing operational costs, minimizing human error, and enhancing the overall reliability and performance of the power plants. As the demand for electricity continues to rise globally, the market for thermal power plant control systems is expected to grow, driven by the need for modernizing existing plants and the construction of new ones to meet energy demands. The market encompasses a range of technologies and solutions, including Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, and other specialized control technologies tailored for thermal power applications.

Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) Systems, Others in the Global Thermal Power Plant Control System Market:

Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) Systems, and other control technologies play a pivotal role in the Global Thermal Power Plant Control System Market. DCS is a type of automated control system that is distributed throughout a power plant to provide precise control over various processes. It consists of multiple controllers that are interconnected through a network, allowing for real-time monitoring and control of plant operations. DCS is particularly beneficial in thermal power plants as it enables operators to manage complex processes such as fuel combustion, steam generation, and turbine control with high accuracy and reliability. The system's ability to integrate with other plant systems and provide comprehensive data analysis helps in optimizing plant performance and reducing downtime. SCADA systems, on the other hand, are designed to provide a centralized control and monitoring solution for power plants. They collect data from various sensors and equipment across the plant and present it in a user-friendly interface for operators to monitor and control. SCADA systems are essential for ensuring the smooth operation of thermal power plants by providing real-time data on plant performance, identifying potential issues, and enabling quick decision-making. They also facilitate remote monitoring and control, allowing operators to manage plant operations from a central location or even from remote sites. This capability is particularly valuable for large power plants or those located in remote areas where on-site monitoring may be challenging. In addition to DCS and SCADA, other control technologies are also employed in thermal power plants to enhance their operational efficiency and reliability. These include advanced process control (APC) systems, which use sophisticated algorithms and models to optimize plant processes and improve energy efficiency. APC systems can predict and adjust plant operations in real-time, ensuring optimal performance and reducing fuel consumption. Furthermore, safety instrumented systems (SIS) are implemented to ensure the safe operation of power plants by automatically shutting down processes in case of emergencies or abnormal conditions. These systems are critical for preventing accidents and ensuring compliance with safety regulations. The integration of these control technologies in thermal power plants not only improves their operational efficiency but also contributes to reducing their environmental impact. By optimizing fuel combustion and minimizing emissions, these systems help power plants meet stringent environmental standards and reduce their carbon footprint. Moreover, the use of advanced data analytics and machine learning in control systems enables predictive maintenance, allowing operators to identify potential equipment failures before they occur and schedule maintenance activities accordingly. This proactive approach reduces unplanned downtime and extends the lifespan of plant equipment. Overall, the combination of DCS, SCADA, and other control technologies provides a comprehensive solution for managing and optimizing the operations of thermal power plants. As the demand for electricity continues to grow, the adoption of these advanced control systems is expected to increase, driving the growth of the Global Thermal Power Plant Control System Market. The ongoing advancements in control technologies, such as the integration of artificial intelligence and the Internet of Things (IoT), are likely to further enhance the capabilities of these systems, enabling more efficient and sustainable power generation.

Coal-Fired Power Plant, Oil-Fired Power Plant, Gas-Fired Power Plant in the Global Thermal Power Plant Control System Market:

The usage of Global Thermal Power Plant Control System Market technologies varies across different types of power plants, including coal-fired, oil-fired, and gas-fired power plants. Each type of plant has its unique operational requirements and challenges, which are addressed through tailored control system solutions. In coal-fired power plants, control systems are essential for managing the complex processes involved in converting coal into electricity. These plants require precise control over the combustion process to ensure efficient fuel utilization and minimize emissions. DCS and SCADA systems are commonly used to monitor and control the various stages of coal handling, combustion, steam generation, and electricity production. By providing real-time data and control capabilities, these systems help operators optimize plant performance, reduce fuel consumption, and comply with environmental regulations. Additionally, advanced process control systems are employed to enhance the efficiency of coal-fired power plants by optimizing combustion conditions and reducing emissions of pollutants such as sulfur dioxide and nitrogen oxides. Oil-fired power plants, on the other hand, rely on control systems to manage the combustion of oil and the subsequent generation of electricity. These plants require precise control over fuel flow, combustion air, and steam generation to ensure efficient and reliable operation. DCS and SCADA systems are used to monitor and control these processes, providing operators with real-time data on plant performance and enabling quick adjustments to optimize efficiency. The integration of advanced control technologies, such as model predictive control and adaptive control, further enhances the performance of oil-fired power plants by improving fuel efficiency and reducing emissions. Safety instrumented systems are also crucial in oil-fired plants to ensure safe operation and prevent accidents, particularly in handling and storing large quantities of oil. Gas-fired power plants, which are known for their high efficiency and lower emissions compared to coal and oil-fired plants, also benefit from advanced control systems. These plants require precise control over the combustion of natural gas and the operation of gas turbines to achieve optimal performance. DCS and SCADA systems are used to monitor and control the various processes involved in gas-fired power generation, including fuel supply, combustion, and electricity production. The use of advanced process control technologies, such as real-time optimization and predictive maintenance, further enhances the efficiency and reliability of gas-fired power plants. By optimizing combustion conditions and predicting equipment failures, these systems help reduce fuel consumption, minimize emissions, and extend the lifespan of plant equipment. Overall, the Global Thermal Power Plant Control System Market provides essential solutions for optimizing the operations of coal-fired, oil-fired, and gas-fired power plants. By integrating advanced control technologies, these systems help power plants achieve higher efficiency, lower emissions, and improved reliability. As the demand for electricity continues to rise, the adoption of these control systems is expected to increase, driving the growth of the market. The ongoing advancements in control technologies, such as the integration of artificial intelligence and machine learning, are likely to further enhance the capabilities of these systems, enabling more efficient and sustainable power generation across different types of thermal power plants.

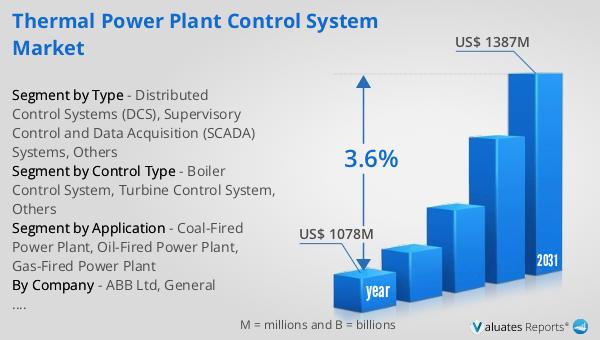

Global Thermal Power Plant Control System Market Outlook:

The global market for Thermal Power Plant Control Systems was valued at approximately $1,078 million in 2024. This market is anticipated to expand, reaching an estimated size of $1,387 million by the year 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.6% over the forecast period. The increase in market size reflects the rising demand for efficient and reliable control systems in thermal power plants worldwide. As the energy sector continues to evolve, there is a growing need for modernizing existing power plants and constructing new ones to meet the increasing demand for electricity. This, in turn, drives the demand for advanced control systems that can optimize plant operations, reduce emissions, and enhance overall efficiency. The projected growth in the market also highlights the importance of investing in innovative control technologies that can address the unique challenges faced by thermal power plants, such as fuel efficiency, emission reduction, and operational reliability. As the market continues to expand, it presents significant opportunities for companies involved in the development and implementation of thermal power plant control systems to capitalize on the growing demand and contribute to the sustainable generation of electricity.

| Report Metric | Details |

| Report Name | Thermal Power Plant Control System Market |

| Accounted market size in year | US$ 1078 million |

| Forecasted market size in 2031 | US$ 1387 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Control Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ABB Ltd, General Electric Company (GE), Honeywell International Inc., Emerson Electric Co., Siemens AG, Mitsubishi Hitachi Power Systems Ltd, Rockwell Automation, Schneider Electric SE, Toshiba Corporation, Yokogawa Electric Corporation, Omron Corporation, Endress+Hauser AG, Petrotech, Inc., HF Controls, ETAP, Mitsubishi Power, Hitachi, SAC-China, AsiaInfo Technologies Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |