What is Global Furnace Extensometers Market?

The Global Furnace Extensometers Market is a specialized segment within the broader field of materials testing and measurement. Furnace extensometers are precision instruments used to measure the deformation or strain of materials when subjected to high temperatures. These devices are crucial in industries where materials are exposed to extreme heat, such as metallurgy, aerospace, and power generation. The market for these instruments is driven by the need for accurate and reliable data on material behavior under thermal stress, which is essential for ensuring safety, performance, and compliance with industry standards. As industries continue to innovate and develop new materials and processes, the demand for advanced testing equipment like furnace extensometers is expected to grow. This market encompasses various types of extensometers, including single-axis, dual-axis, and multi-axis models, each designed to meet specific testing requirements. The global reach of this market is indicative of the widespread need for high-quality testing solutions across different sectors and regions. As technology advances, the capabilities of furnace extensometers are also evolving, offering more precise measurements and greater durability in harsh testing environments. This evolution is likely to continue, driven by ongoing research and development efforts in the field.

Single-axis Furnace Extensometers, Dual-axis Furnace Extensometers, Multi-axis Furnace Extensometers in the Global Furnace Extensometers Market:

Single-axis furnace extensometers are designed to measure strain in one direction, making them ideal for applications where the primary interest is in the elongation or compression of a material along a single axis. These extensometers are often used in basic tensile testing, where the focus is on understanding how a material stretches or compresses under load. They are relatively simple in design, which makes them cost-effective and easy to use. However, their simplicity also means they may not capture the full complexity of material behavior in situations where multi-directional forces are at play. Dual-axis furnace extensometers, on the other hand, provide measurements in two directions, typically capturing both longitudinal and transverse strain. This capability is particularly useful in applications where materials are subjected to complex loading conditions, such as in the aerospace industry, where components may experience forces from multiple directions simultaneously. By capturing data in two axes, these extensometers offer a more comprehensive understanding of material behavior, which can be critical for ensuring the safety and performance of high-stakes components. Multi-axis furnace extensometers take this a step further by measuring strain in multiple directions, providing a three-dimensional view of how a material deforms under stress. These advanced instruments are essential for testing materials that are used in highly complex and demanding environments, such as in the development of new alloys or composite materials. The ability to capture data in multiple dimensions allows engineers and researchers to gain a deeper understanding of material properties, leading to more informed decisions about material selection and design. In the Global Furnace Extensometers Market, the choice between single-axis, dual-axis, and multi-axis models depends largely on the specific requirements of the testing application. Each type of extensometer offers unique advantages and is suited to different testing scenarios. As industries continue to push the boundaries of material science, the demand for more sophisticated testing equipment is likely to increase, driving further innovation in the design and functionality of furnace extensometers. This ongoing evolution reflects the critical role these instruments play in advancing our understanding of material behavior and ensuring the safety and reliability of products across a wide range of industries.

Metallurgy, Power Generation, Aerospace & Defense, Others in the Global Furnace Extensometers Market:

The Global Furnace Extensometers Market finds significant application across various industries, each with its unique requirements and challenges. In the field of metallurgy, furnace extensometers are indispensable tools for testing the properties of metals and alloys at high temperatures. These instruments help metallurgists understand how different materials behave under thermal stress, which is crucial for developing new alloys and improving existing ones. By providing accurate data on material deformation, extensometers enable researchers to optimize the composition and processing of metals, leading to stronger and more durable products. In the power generation sector, furnace extensometers are used to test materials that are exposed to extreme temperatures in power plants, such as turbine blades and boiler components. These materials must withstand high thermal and mechanical stresses to ensure the efficient and safe operation of power generation equipment. Extensometers provide critical data on how these materials perform under operational conditions, helping engineers design components that can endure the harsh environments of power plants. In the aerospace and defense industries, the use of furnace extensometers is essential for testing materials used in aircraft and military equipment. These industries demand materials that can withstand extreme temperatures and pressures, as well as resist fatigue and wear over time. Extensometers help engineers evaluate the performance of materials under these conditions, ensuring that they meet the stringent safety and performance standards required in these high-stakes fields. Beyond these specific industries, furnace extensometers are also used in a variety of other applications, including research and development, quality control, and product testing. In research and development, extensometers provide valuable data that can lead to breakthroughs in material science and engineering. In quality control, they help manufacturers ensure that their products meet the required specifications and standards. In product testing, extensometers are used to evaluate the performance of materials and components under simulated operational conditions, providing insights that can lead to improved designs and processes. Overall, the Global Furnace Extensometers Market plays a vital role in advancing our understanding of material behavior and ensuring the safety and reliability of products across a wide range of industries. As technology continues to evolve, the capabilities of furnace extensometers are likely to expand, offering even greater precision and versatility in testing applications. This ongoing evolution reflects the critical importance of these instruments in supporting innovation and progress in material science and engineering.

Global Furnace Extensometers Market Outlook:

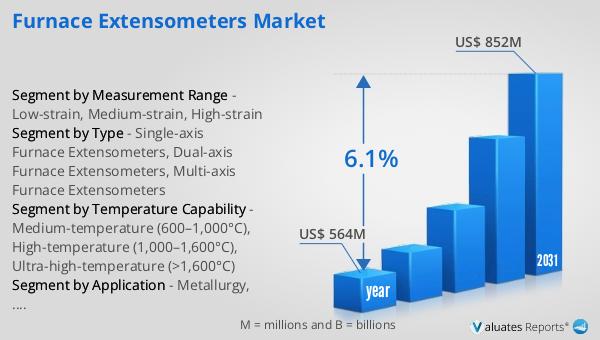

In 2024, the global market for furnace extensometers was valued at approximately $564 million. This market is anticipated to grow significantly over the coming years, reaching an estimated value of $852 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.1% during the forecast period. The increasing demand for accurate and reliable testing equipment across various industries is a key driver of this market expansion. As industries such as metallurgy, aerospace, and power generation continue to innovate and develop new materials and processes, the need for advanced testing solutions like furnace extensometers becomes increasingly critical. These instruments provide essential data on material behavior under thermal stress, enabling engineers and researchers to make informed decisions about material selection and design. The projected growth of the Global Furnace Extensometers Market reflects the ongoing advancements in material science and engineering, as well as the increasing emphasis on safety and performance in high-stakes industries. As technology continues to evolve, the capabilities of furnace extensometers are likely to expand, offering even greater precision and versatility in testing applications. This ongoing evolution underscores the critical role these instruments play in supporting innovation and progress across a wide range of sectors.

| Report Metric | Details |

| Report Name | Furnace Extensometers Market |

| Accounted market size in year | US$ 564 million |

| Forecasted market size in 2031 | US$ 852 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Temperature Capability |

|

| Segment by Measurement Range |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Epsilon Technology, Instron, MTS Systems, Tinius Olsen, ZwickRoell, Hegewald & Peschke, Sandner Messtechnik, Walter+Bai, Galdabini, Shimadzu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |