What is Global Automotive Parts Electrophoretic Paint Market?

The Global Automotive Parts Electrophoretic Paint Market is a specialized segment within the automotive industry that focuses on the application of electrophoretic paint, commonly known as e-coat, to automotive parts. This market is driven by the need for durable, corrosion-resistant coatings that enhance the longevity and aesthetic appeal of automotive components. Electrophoretic painting is a process where charged paint particles are deposited onto a conductive surface, ensuring even coverage and strong adhesion. This method is particularly valued for its efficiency and environmental benefits, as it reduces waste and emissions compared to traditional painting techniques. The market encompasses a wide range of automotive parts, including body panels, chassis components, and other metal parts that require protective coatings. As the automotive industry continues to evolve with advancements in technology and materials, the demand for high-quality electrophoretic paint solutions is expected to grow, driven by the increasing focus on sustainability and performance. The market's growth is also influenced by regulatory standards and consumer preferences for vehicles that offer both durability and aesthetic appeal. Overall, the Global Automotive Parts Electrophoretic Paint Market plays a crucial role in ensuring the quality and longevity of automotive components.

Cathodic E-coat, Anodic E-coat in the Global Automotive Parts Electrophoretic Paint Market:

Cathodic and anodic e-coats are two primary types of electrophoretic coatings used in the Global Automotive Parts Electrophoretic Paint Market, each with distinct characteristics and applications. Cathodic e-coat is the more commonly used type, known for its superior corrosion resistance and durability. In this process, the automotive part acts as the cathode, attracting positively charged paint particles. This results in a robust coating that provides excellent protection against harsh environmental conditions, making it ideal for parts exposed to the elements, such as underbody components and exterior panels. The cathodic e-coat is particularly favored in the automotive industry due to its ability to provide a uniform, high-quality finish that enhances both the performance and appearance of vehicles. On the other hand, anodic e-coat involves the automotive part serving as the anode, attracting negatively charged paint particles. While anodic e-coats are generally less corrosion-resistant than cathodic e-coats, they offer advantages in terms of color variety and gloss. This makes them suitable for interior components and parts where aesthetic considerations are paramount. Anodic e-coats are often used in applications where the primary focus is on achieving a specific visual effect or where the parts are not subjected to extreme environmental conditions. Both cathodic and anodic e-coats contribute to the overall efficiency and sustainability of the painting process. They allow for precise control over the thickness and uniformity of the coating, reducing material waste and energy consumption. Additionally, the use of water-based formulations in e-coating processes minimizes the release of volatile organic compounds (VOCs), aligning with environmental regulations and industry standards. The choice between cathodic and anodic e-coats depends on various factors, including the specific requirements of the automotive part, the desired level of corrosion resistance, and the aesthetic preferences of manufacturers and consumers. As the automotive industry continues to innovate and prioritize sustainability, the demand for advanced electrophoretic paint solutions is expected to rise. Manufacturers are investing in research and development to enhance the performance and versatility of both cathodic and anodic e-coats, ensuring they meet the evolving needs of the market. This includes exploring new formulations and technologies that offer improved adhesion, faster curing times, and enhanced resistance to chemicals and abrasion. The Global Automotive Parts Electrophoretic Paint Market is poised for growth as it adapts to the changing landscape of the automotive industry, driven by the increasing emphasis on quality, sustainability, and innovation.

Passenger Cars, Commercial Vehicles in the Global Automotive Parts Electrophoretic Paint Market:

The usage of electrophoretic paint in the Global Automotive Parts Electrophoretic Paint Market is particularly significant in the areas of passenger cars and commercial vehicles, each with distinct requirements and applications. In passenger cars, electrophoretic paint is primarily used to enhance the durability and aesthetic appeal of various components. The process ensures that parts such as body panels, doors, and hoods receive a uniform and high-quality finish, which is crucial for maintaining the vehicle's appearance and resale value. The corrosion resistance provided by electrophoretic paint is especially important for passenger cars, as it protects against rust and environmental damage, extending the lifespan of the vehicle. Additionally, the ability to achieve a smooth and even coating contributes to the overall aesthetic appeal, meeting consumer expectations for visually appealing vehicles. In commercial vehicles, the focus is often on durability and performance, as these vehicles are typically subjected to more demanding conditions. Electrophoretic paint plays a critical role in protecting components such as chassis, frames, and other structural parts from corrosion and wear. The robust coating provided by electrophoretic paint ensures that commercial vehicles can withstand harsh environments and heavy usage, reducing maintenance costs and downtime. This is particularly important for industries that rely on commercial vehicles for transportation and logistics, where reliability and longevity are key considerations. The use of electrophoretic paint in commercial vehicles also aligns with industry standards and regulations, which often require high levels of corrosion resistance and environmental compliance. The water-based formulations used in electrophoretic painting processes help minimize the release of harmful emissions, supporting sustainability initiatives and reducing the environmental impact of vehicle manufacturing. As the automotive industry continues to evolve, the demand for high-quality electrophoretic paint solutions in both passenger cars and commercial vehicles is expected to grow. Manufacturers are increasingly focusing on developing advanced coatings that offer enhanced performance, sustainability, and cost-effectiveness. This includes exploring new technologies and materials that improve the efficiency and effectiveness of the electrophoretic painting process, ensuring that it meets the diverse needs of the automotive market. Overall, the Global Automotive Parts Electrophoretic Paint Market plays a vital role in ensuring the quality, durability, and aesthetic appeal of both passenger cars and commercial vehicles, contributing to the overall success and competitiveness of the automotive industry.

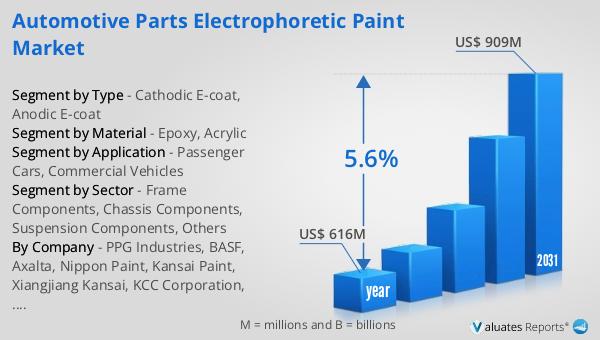

Global Automotive Parts Electrophoretic Paint Market Outlook:

In 2024, the global market for Automotive Parts Electrophoretic Paint was valued at approximately $616 million. This market is anticipated to expand significantly, reaching an estimated value of $909 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.6% over the forecast period. The increasing demand for durable and environmentally friendly coatings in the automotive industry is a key driver of this growth. Electrophoretic paint offers several advantages, including superior corrosion resistance, uniform coverage, and reduced environmental impact, making it an attractive choice for automotive manufacturers. As the industry continues to prioritize sustainability and performance, the adoption of electrophoretic paint solutions is expected to rise. This growth is further supported by advancements in technology and materials, which enhance the efficiency and effectiveness of the electrophoretic painting process. Additionally, regulatory standards and consumer preferences for vehicles that offer both durability and aesthetic appeal are contributing to the market's expansion. Overall, the Global Automotive Parts Electrophoretic Paint Market is poised for significant growth, driven by the increasing emphasis on quality, sustainability, and innovation in the automotive industry.

| Report Metric | Details |

| Report Name | Automotive Parts Electrophoretic Paint Market |

| Accounted market size in year | US$ 616 million |

| Forecasted market size in 2031 | US$ 909 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Material |

|

| Segment by Sector |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PPG Industries, BASF, Axalta, Nippon Paint, Kansai Paint, Xiangjiang Kansai, KCC Corporation, Kinlita, Haolisen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |