What is Global Copper Base Braze Alloys Market?

The Global Copper Base Braze Alloys Market is a specialized and in-depth study of the copper base braze alloys industry with a focus on the global market trend. Copper base braze alloys are a type of brazing filler material that is used in brazing, a metal-joining process wherein a filler metal is heated above melting point and distributed between two or more close-fitting parts by capillary action. The filler metal is brought slightly above its melting (liquidus) temperature while protecting it with a suitable atmosphere, usually a flux. It then flows over the base metal (known as wetting) and is then cooled to join the work pieces together. A major use of copper base braze alloys is in the manufacturing of various industrial products such as turbines, heat exchangers, and sub-assembly sensors. The global copper base braze alloys market is driven by various factors such as the increasing demand for efficient and high-performance brazing materials in various end-use industries, and the growing industrialization and urbanization in developing countries. However, the market faces certain challenges such as the high cost of copper base braze alloys and the technical issues related to brazing process. Despite these challenges, the global copper base braze alloys market is expected to grow significantly in the coming years.

Torch Brazing, Furnace Brazing, Induction Brazing, Infrared brazing, Others in the Global Copper Base Braze Alloys Market:

Brazing is a versatile and robust metal joining process that has a wide range of applications in various industries. There are several types of brazing methods used in the global copper base braze alloys market, including torch brazing, furnace brazing, induction brazing, infrared brazing, and others. Torch brazing is the most common method of brazing, which involves the use of a gas flame to heat the base metal and the filler metal. Furnace brazing is a semi-automatic process that is used for large scale production and it offers excellent control over temperature and atmosphere. Induction brazing uses electromagnetic fields to generate heat and it is known for its speed, precision, and energy efficiency. Infrared brazing is a relatively new method that uses infrared radiation to heat the base metal and the filler metal. Each of these brazing methods has its own advantages and disadvantages, and the choice of method depends on various factors such as the type of materials to be joined, the desired joint strength, and the production volume.

Turbines, Heat Exchangers, Sub-Assembly Sensors, Others in the Global Copper Base Braze Alloys Market:

The global copper base braze alloys market finds extensive application in various areas such as turbines, heat exchangers, sub-assembly sensors, and others. In turbines, copper base braze alloys are used to join turbine blades to the turbine disc. This is a critical application as the joint has to withstand high temperatures and stresses. In heat exchangers, copper base braze alloys are used to join the tubes to the tube sheets. This is another demanding application as the joint has to resist corrosion and erosion. In sub-assembly sensors, copper base braze alloys are used to join sensor elements to their housings. This is a precision application as the joint has to maintain its integrity under various operating conditions. Other applications of copper base braze alloys include joining components in electrical and electronic devices, automotive parts, and various types of machinery.

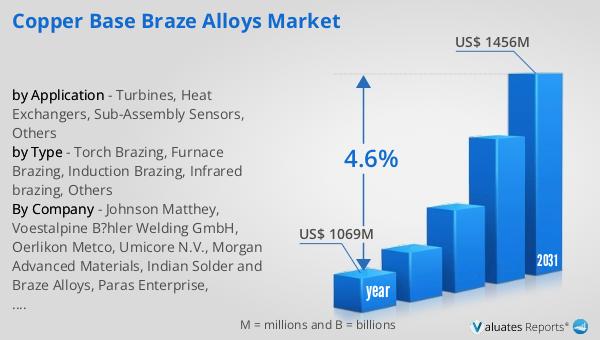

Global Copper Base Braze Alloys Market Outlook:

According to a recent survey, the global Copper Base Braze Alloys market is expected to experience a significant growth in the coming years. The market size, which was valued at US$ 985.6 million in 2022, is projected to reach US$ 1342.6 million by 2029. This represents a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2023 to 2029. This growth can be attributed to several factors such as the increasing demand for copper base braze alloys in various end-use industries, the technological advancements in brazing processes, and the growing industrialization and urbanization in developing countries. However, the market growth may be hindered by certain challenges such as the high cost of copper base braze alloys and the technical issues related to brazing process. Despite these challenges, the global copper base braze alloys market is expected to offer lucrative opportunities for the market players in the coming years.

| Report Metric | Details |

| Report Name | Copper Base Braze Alloys Market |

| Accounted market size in 2022 | US$ 985.6 million |

| Forecasted market size in 2029 | US$ 1342.6 million |

| CAGR | 4.6% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Johnson Matthey, Voestalpine B?hler Welding GmbH, Oerlikon Metco, Umicore N.V., Morgan Advanced Materials, Indian Solder and Braze Alloys, Paras Enterprise, Lucas-Milhaupt Inc., Bellman-Melcor, Aimtek, Inc., Harris Products Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |