What is Global Differential Pressure Sensors for HVAC Applications Market?

The Global Differential Pressure Sensors for HVAC Applications Market is a specialized segment within the broader HVAC (Heating, Ventilation, and Air Conditioning) industry. These sensors are crucial components used to measure the difference in pressure between two points, which is essential for maintaining optimal airflow and ensuring efficient system performance. In HVAC systems, differential pressure sensors help in monitoring and controlling air pressure across filters, fans, and ducts, which is vital for energy efficiency and maintaining indoor air quality. The market for these sensors is driven by the increasing demand for energy-efficient HVAC systems, stringent environmental regulations, and the growing awareness of indoor air quality. As buildings become more complex and energy standards more stringent, the need for precise and reliable pressure measurement becomes even more critical. These sensors are used in various applications, including commercial, residential, industrial, and government buildings, each with specific requirements and challenges. The market is characterized by technological advancements, with manufacturers focusing on developing sensors that offer higher accuracy, reliability, and ease of integration into existing systems. As a result, the Global Differential Pressure Sensors for HVAC Applications Market is poised for steady growth, driven by the ongoing trends in building automation and energy management.

Digital Differential Pressure Sensors, Analog Differential Pressure Sensors in the Global Differential Pressure Sensors for HVAC Applications Market:

Digital Differential Pressure Sensors and Analog Differential Pressure Sensors are two primary types of sensors used in the Global Differential Pressure Sensors for HVAC Applications Market. Digital Differential Pressure Sensors are known for their precision and advanced features. They convert the pressure difference into a digital signal, which can be easily integrated into modern HVAC systems. These sensors often come with features like digital displays, programmable settings, and connectivity options, making them ideal for smart building applications. They offer high accuracy and are less susceptible to signal degradation over long distances, which is a significant advantage in large commercial or industrial buildings. Digital sensors are also easier to calibrate and maintain, providing long-term reliability and performance. On the other hand, Analog Differential Pressure Sensors are more traditional and have been used in HVAC systems for many years. They convert the pressure difference into an analog signal, typically a voltage or current, which is then interpreted by the HVAC system. While they may lack some of the advanced features of digital sensors, analog sensors are often more cost-effective and can be a suitable choice for simpler applications or where budget constraints are a concern. They are known for their robustness and ability to operate in harsh environments, making them a reliable choice for industrial applications. Both types of sensors play a crucial role in ensuring the efficient operation of HVAC systems by providing accurate pressure measurements that help in maintaining optimal airflow and energy efficiency. The choice between digital and analog sensors often depends on the specific requirements of the application, including factors like system complexity, budget, and the need for advanced features. As the demand for smart and energy-efficient buildings continues to grow, the market for both digital and analog differential pressure sensors is expected to expand, with manufacturers focusing on innovation and product development to meet the evolving needs of the HVAC industry.

Commercial Buildings, Residential Buildings, Industrial Buildings, Government Public Sectors Buildings in the Global Differential Pressure Sensors for HVAC Applications Market:

The usage of Global Differential Pressure Sensors for HVAC Applications Market spans across various types of buildings, each with unique requirements and challenges. In commercial buildings, these sensors are essential for maintaining optimal indoor air quality and energy efficiency. They help in monitoring and controlling the airflow across different zones, ensuring that the HVAC system operates efficiently and meets the comfort needs of occupants. In large commercial spaces like shopping malls, office buildings, and hospitals, maintaining consistent air pressure is crucial for preventing issues like drafts, hot or cold spots, and energy wastage. Differential pressure sensors play a vital role in achieving this balance by providing accurate pressure measurements that guide the HVAC system's operation. In residential buildings, the focus is often on comfort and energy savings. Differential pressure sensors help in optimizing the performance of HVAC systems by ensuring that air filters are clean and ducts are free from blockages. This not only improves indoor air quality but also reduces energy consumption, leading to lower utility bills for homeowners. In industrial buildings, the requirements are more stringent due to the presence of machinery and processes that generate heat and require precise temperature and humidity control. Differential pressure sensors are used to monitor and control the airflow in these environments, ensuring that the HVAC system can handle the demands of the industrial processes while maintaining a safe and comfortable environment for workers. In government and public sector buildings, the emphasis is often on compliance with environmental regulations and energy efficiency standards. Differential pressure sensors help in achieving these goals by providing accurate data that can be used to optimize the performance of HVAC systems, reduce energy consumption, and ensure compliance with regulations. Overall, the usage of differential pressure sensors in HVAC applications is critical for maintaining optimal indoor environments, improving energy efficiency, and ensuring compliance with regulations across various types of buildings.

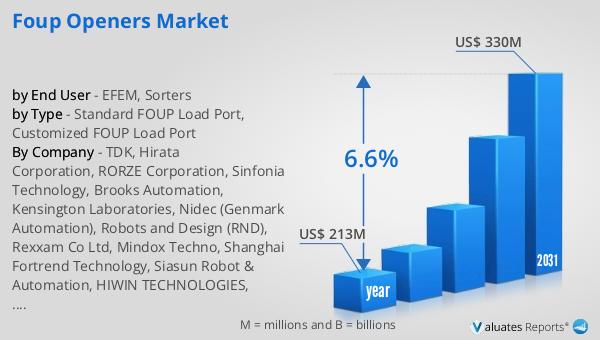

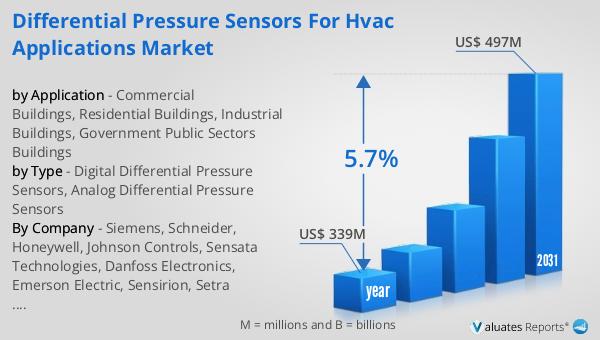

Global Differential Pressure Sensors for HVAC Applications Market Outlook:

The global market for Differential Pressure Sensors for HVAC Applications was valued at US$ 339 million in 2024 and is projected to reach a revised size of US$ 497 million by 2031, growing at a CAGR of 5.7% during the forecast period. This growth is driven by several factors, including the increasing demand for energy-efficient HVAC systems, the growing awareness of indoor air quality, and the need for compliance with environmental regulations. As buildings become more complex and energy standards more stringent, the demand for precise and reliable pressure measurement solutions is expected to rise. Differential pressure sensors play a crucial role in ensuring the efficient operation of HVAC systems by providing accurate pressure measurements that help in maintaining optimal airflow and energy efficiency. The market is characterized by technological advancements, with manufacturers focusing on developing sensors that offer higher accuracy, reliability, and ease of integration into existing systems. As a result, the Global Differential Pressure Sensors for HVAC Applications Market is poised for steady growth, driven by the ongoing trends in building automation and energy management. The increasing adoption of smart building technologies and the growing emphasis on sustainability are also expected to contribute to the market's expansion. Overall, the outlook for the Global Differential Pressure Sensors for HVAC Applications Market is positive, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Differential Pressure Sensors for HVAC Applications Market |

| Accounted market size in year | US$ 339 million |

| Forecasted market size in 2031 | US$ 497 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens, Schneider, Honeywell, Johnson Controls, Sensata Technologies, Danfoss Electronics, Emerson Electric, Sensirion, Setra Systems, Inc., BAPI, Greystone Energy Systems, Cleveland Controls, MAMAC Systems, E+E Elektronik Ges.m.b.H |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |