What is Global 3D Automated Optical Inspection Equipment in PCB Market?

Global 3D Automated Optical Inspection (AOI) Equipment in the PCB market refers to advanced technology used to inspect printed circuit boards (PCBs) for defects during the manufacturing process. This equipment utilizes 3D imaging to provide a detailed analysis of the PCB, ensuring that all components are correctly placed and soldered. The technology is crucial in maintaining high-quality standards in PCB production, as it can detect issues such as misalignment, missing components, and soldering defects that might not be visible to the naked eye. By using 3D AOI, manufacturers can reduce the risk of faulty products reaching the market, thereby saving costs associated with recalls and repairs. The global demand for this technology is driven by the increasing complexity of PCBs, which are integral to a wide range of electronic devices. As electronics become more sophisticated, the need for precise and reliable inspection methods like 3D AOI becomes even more critical. This market is characterized by continuous innovation, with companies investing in research and development to enhance the capabilities of AOI systems, making them faster, more accurate, and easier to integrate into existing manufacturing processes.

Inline 3D AOI, Offline 3D AOI in the Global 3D Automated Optical Inspection Equipment in PCB Market:

Inline 3D AOI and Offline 3D AOI are two primary types of inspection systems used in the Global 3D Automated Optical Inspection Equipment in the PCB market. Inline 3D AOI systems are integrated directly into the production line, allowing for real-time inspection of PCBs as they are manufactured. This integration enables immediate detection and correction of defects, minimizing downtime and ensuring a smooth production process. Inline systems are particularly beneficial in high-volume manufacturing environments where speed and efficiency are critical. They provide continuous monitoring and can quickly alert operators to any issues, allowing for rapid intervention. On the other hand, Offline 3D AOI systems are used separately from the production line. These systems are typically employed for detailed analysis and quality control, often inspecting samples from a batch rather than every single unit. Offline AOI systems are ideal for low-volume production or for manufacturers who require a more thorough inspection process. They offer flexibility, as they can be used to inspect a wide range of PCB designs without disrupting the main production line. Both Inline and Offline 3D AOI systems utilize advanced imaging technology to create a three-dimensional representation of the PCB, which is then analyzed for defects. The choice between Inline and Offline systems depends on various factors, including production volume, the complexity of the PCBs, and the specific quality control requirements of the manufacturer. Inline systems are generally preferred for large-scale operations where speed is essential, while Offline systems are favored in scenarios where detailed inspection and flexibility are more important. Both types of systems contribute significantly to improving the overall quality and reliability of PCBs, which are crucial components in modern electronic devices. As the demand for more complex and miniaturized electronics continues to grow, the role of 3D AOI systems in ensuring the quality and functionality of PCBs becomes increasingly vital. Manufacturers are continually seeking ways to enhance the capabilities of these systems, incorporating features such as artificial intelligence and machine learning to improve accuracy and efficiency. The ongoing development and adoption of Inline and Offline 3D AOI systems reflect the broader trends in the electronics manufacturing industry, where precision, speed, and reliability are paramount.

Automotive Electronics, Consumer Electronics, Industrials, Others in the Global 3D Automated Optical Inspection Equipment in PCB Market:

The usage of Global 3D Automated Optical Inspection Equipment in the PCB market spans several key areas, including automotive electronics, consumer electronics, industrials, and others. In the automotive electronics sector, 3D AOI systems are essential for ensuring the reliability and safety of electronic components used in vehicles. As cars become increasingly reliant on electronic systems for functions such as navigation, entertainment, and safety features, the need for high-quality PCBs becomes critical. 3D AOI systems help manufacturers detect and correct defects early in the production process, reducing the risk of failures that could lead to costly recalls or safety issues. In the consumer electronics industry, the demand for smaller, more powerful devices drives the need for precise and reliable PCB inspection. 3D AOI systems enable manufacturers to maintain high-quality standards while keeping up with the rapid pace of innovation in this sector. By ensuring that PCBs are free from defects, these systems help prevent issues that could lead to product malfunctions or customer dissatisfaction. In industrial applications, 3D AOI systems are used to inspect PCBs used in a wide range of equipment and machinery. The reliability of these components is crucial, as failures can lead to significant downtime and financial losses. By using 3D AOI systems, manufacturers can ensure that their products meet the stringent quality standards required in industrial settings. Other areas where 3D AOI systems are used include telecommunications, aerospace, and medical devices. In each of these sectors, the quality and reliability of PCBs are of utmost importance, as failures can have serious consequences. 3D AOI systems provide manufacturers with the tools they need to detect and correct defects, ensuring that their products meet the highest standards of quality and performance. As the demand for more complex and reliable electronic devices continues to grow, the role of 3D AOI systems in the PCB market is expected to become even more significant. Manufacturers are continually seeking ways to enhance the capabilities of these systems, incorporating advanced technologies such as artificial intelligence and machine learning to improve accuracy and efficiency. The ongoing development and adoption of 3D AOI systems reflect the broader trends in the electronics manufacturing industry, where precision, speed, and reliability are paramount.

Global 3D Automated Optical Inspection Equipment in PCB Market Outlook:

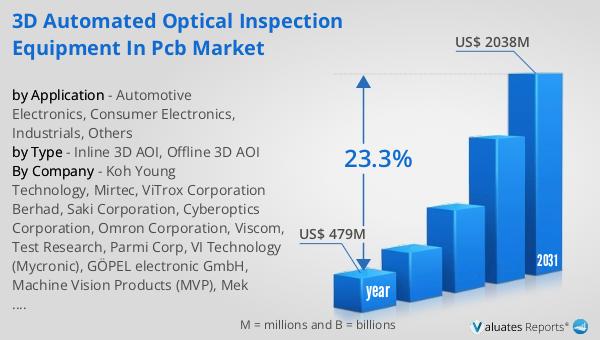

The global market for 3D Automated Optical Inspection Equipment in PCB was valued at $479 million in 2024, with projections indicating a significant growth trajectory. By 2031, the market is expected to expand to a revised size of $2038 million, reflecting a robust compound annual growth rate (CAGR) of 23.3% over the forecast period. This impressive growth underscores the increasing demand for advanced inspection technologies in the PCB manufacturing sector. As electronic devices become more complex and miniaturized, the need for precise and reliable inspection methods like 3D AOI becomes even more critical. The market's expansion is driven by several factors, including the rising adoption of automation in manufacturing processes, the growing complexity of PCBs, and the increasing demand for high-quality electronic components across various industries. Manufacturers are investing heavily in research and development to enhance the capabilities of 3D AOI systems, making them faster, more accurate, and easier to integrate into existing production lines. This trend is expected to continue as companies seek to maintain a competitive edge in the rapidly evolving electronics market. The projected growth of the 3D AOI market highlights the importance of this technology in ensuring the quality and reliability of PCBs, which are essential components in modern electronic devices.

| Report Metric | Details |

| Report Name | 3D Automated Optical Inspection Equipment in PCB Market |

| Accounted market size in year | US$ 479 million |

| Forecasted market size in 2031 | US$ 2038 million |

| CAGR | 23.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Koh Young Technology, Mirtec, ViTrox Corporation Berhad, Saki Corporation, Cyberoptics Corporation, Omron Corporation, Viscom, Test Research, Parmi Corp, VI Technology (Mycronic), GÖPEL electronic GmbH, Machine Vision Products (MVP), Mek Marantz Electronics, Pemtron Corp., Nordson YESTECH, JUTZE Intelligence Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |