What is Global Wafer Processing Transport Carriers Market?

The Global Wafer Processing Transport Carriers Market is a specialized segment within the semiconductor industry that focuses on the transportation and handling of silicon wafers during the manufacturing process. These carriers are essential for ensuring the safe and efficient movement of wafers, which are thin slices of semiconductor material used in the production of integrated circuits and other microdevices. The market encompasses various types of carriers, including Front Opening Unified Pods (FOUPs) and Front Opening Shipping Boxes (FOSBs), which are designed to protect wafers from contamination and physical damage. As the demand for semiconductors continues to grow, driven by advancements in technology and increased consumer electronics usage, the need for reliable wafer transport solutions becomes increasingly critical. The market is characterized by a focus on innovation and quality, with manufacturers striving to develop carriers that meet the stringent requirements of modern semiconductor fabrication facilities. This market plays a pivotal role in the semiconductor supply chain, ensuring that wafers are delivered safely and efficiently from one processing stage to the next, ultimately contributing to the production of high-quality electronic components.

FOUP, FOSB in the Global Wafer Processing Transport Carriers Market:

FOUPs and FOSBs are integral components of the Global Wafer Processing Transport Carriers Market, each serving distinct purposes in the semiconductor manufacturing process. FOUPs, or Front Opening Unified Pods, are specialized containers designed to hold and transport wafers within semiconductor fabrication facilities. They are engineered to provide a controlled environment that minimizes contamination and protects wafers from physical damage. FOUPs are typically used in cleanroom environments, where maintaining the purity of the wafers is paramount. These carriers are equipped with advanced features such as automated handling systems and secure locking mechanisms, ensuring that wafers are safely transported between different processing stations. The design of FOUPs allows for easy integration with automated wafer handling systems, enhancing the efficiency of semiconductor manufacturing operations. On the other hand, FOSBs, or Front Opening Shipping Boxes, are used for the transportation of wafers between different facilities or geographic locations. Unlike FOUPs, which are primarily used within a single facility, FOSBs are designed to withstand the rigors of long-distance transportation. They provide robust protection against environmental factors such as temperature fluctuations and mechanical shocks, ensuring that wafers arrive at their destination in pristine condition. FOSBs are often used in conjunction with FOUPs, with wafers being transferred from FOSBs to FOUPs upon arrival at a fabrication facility. Both FOUPs and FOSBs are critical to the semiconductor supply chain, ensuring that wafers are handled with care and precision throughout the manufacturing process. As the semiconductor industry continues to evolve, the demand for advanced wafer transport solutions like FOUPs and FOSBs is expected to grow, driven by the need for increased efficiency and reliability in wafer handling operations.

300 mm Wafer, 200 mm Wafer in the Global Wafer Processing Transport Carriers Market:

The usage of Global Wafer Processing Transport Carriers Market in the context of 300 mm and 200 mm wafers highlights the importance of these carriers in accommodating different wafer sizes. The 300 mm wafer, being larger, allows for more chips to be produced per wafer, which can lead to cost efficiencies in semiconductor manufacturing. However, the larger size also presents challenges in terms of handling and transportation. FOUPs and FOSBs designed for 300 mm wafers are engineered to provide enhanced stability and protection, ensuring that the wafers are not damaged during movement. These carriers are equipped with features such as reinforced structures and advanced locking mechanisms to accommodate the increased weight and size of 300 mm wafers. In contrast, 200 mm wafers, while smaller, still require careful handling to prevent contamination and physical damage. The carriers used for 200 mm wafers are typically more compact but are designed with the same level of precision and protection as those used for larger wafers. The choice of carrier depends on the specific requirements of the manufacturing process, with considerations such as automation compatibility and environmental control playing a crucial role. Both 300 mm and 200 mm wafer carriers are essential for maintaining the integrity of the wafers throughout the production process, ensuring that they are delivered safely and efficiently to each processing stage. As semiconductor technology advances, the demand for versatile and reliable wafer transport solutions continues to grow, highlighting the critical role of the Global Wafer Processing Transport Carriers Market in supporting the industry's needs.

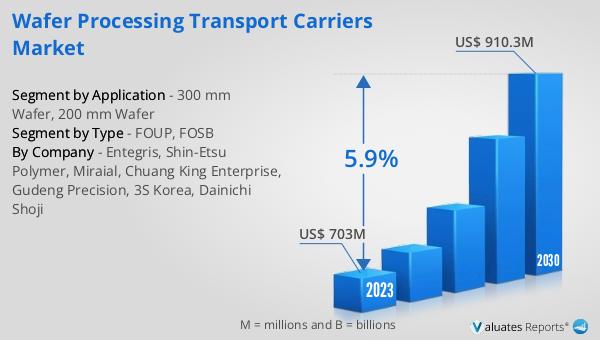

Global Wafer Processing Transport Carriers Market Outlook:

The global market for Wafer Processing Transport Carriers was valued at $680 million in 2024, with projections indicating a growth to $1009 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. Taiwan emerges as the leading consumer region for wafer cassettes, accounting for nearly 19.75% of the consumption market share in 2022. This significant consumption underscores Taiwan's pivotal role in the semiconductor industry, driven by its robust manufacturing capabilities and technological advancements. The market is highly concentrated, with the top five companies commanding a substantial 96.32% of the global market share. This concentration highlights the competitive nature of the market, where leading players leverage their expertise and resources to maintain a dominant position. The growth trajectory of the Wafer Processing Transport Carriers Market is indicative of the increasing demand for efficient and reliable wafer handling solutions, driven by the expanding semiconductor industry and the need for advanced electronic devices. As the market continues to evolve, companies are likely to focus on innovation and quality to meet the stringent requirements of modern semiconductor fabrication facilities, ensuring the safe and efficient transport of wafers throughout the manufacturing process.

| Report Metric | Details |

| Report Name | Wafer Processing Transport Carriers Market |

| Accounted market size in year | US$ 680 million |

| Forecasted market size in 2031 | US$ 1009 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Entegris, Shin-Etsu Polymer, Miraial, Chuang King Enterprise, Gudeng Precision, 3S Korea, Dainichi Shoji |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |