What is Global Integrated Circuit Packaging Solder Ball Market?

The Global Integrated Circuit Packaging Solder Ball Market is a specialized segment within the electronics industry that focuses on the production and distribution of solder balls used in integrated circuit (IC) packaging. Solder balls are tiny spheres of solder that serve as electrical connections between the IC and the printed circuit board (PCB). These components are crucial in ensuring the functionality and reliability of electronic devices, as they facilitate the transfer of electrical signals. The market for these solder balls is driven by the increasing demand for miniaturized and high-performance electronic devices, such as smartphones, tablets, and other consumer electronics. As technology advances, the need for efficient and reliable IC packaging solutions grows, propelling the market forward. The market is characterized by a variety of solder ball types, including lead and lead-free options, each catering to different regulatory and performance requirements. The ongoing trend towards environmentally friendly and sustainable manufacturing practices also influences the market, as manufacturers seek to comply with global regulations and reduce their environmental impact. Overall, the Global Integrated Circuit Packaging Solder Ball Market plays a vital role in the electronics industry, supporting the development and production of cutting-edge technologies.

Lead Solder Ball, Lead Free Solder Ball in the Global Integrated Circuit Packaging Solder Ball Market:

Lead Solder Balls and Lead-Free Solder Balls are two primary types of solder balls used in the Global Integrated Circuit Packaging Solder Ball Market. Lead Solder Balls, traditionally composed of a tin-lead alloy, have been widely used due to their excellent mechanical properties and ease of use. They offer reliable electrical connections and are known for their ability to withstand thermal cycling, making them suitable for various electronic applications. However, the use of lead in solder balls has raised environmental and health concerns, leading to the development and adoption of Lead-Free Solder Balls. Lead-Free Solder Balls are made from alternative materials, such as tin-silver-copper (SAC) alloys, which provide similar performance characteristics without the harmful effects of lead. The transition to lead-free options has been driven by stringent regulations, such as the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electronic products. Despite the challenges associated with lead-free soldering, such as higher melting points and potential reliability issues, advancements in material science and manufacturing processes have improved the performance and reliability of Lead-Free Solder Balls. As a result, they have become the preferred choice for many manufacturers seeking to comply with environmental regulations and meet consumer demand for eco-friendly products. The shift towards lead-free solutions has also spurred innovation in the market, with companies investing in research and development to enhance the properties of Lead-Free Solder Balls, such as improving their thermal and mechanical performance. This ongoing innovation is crucial for meeting the evolving needs of the electronics industry, as devices become more complex and require more sophisticated packaging solutions. Additionally, the growing trend towards miniaturization and increased functionality in electronic devices has further fueled the demand for high-performance solder balls, both lead and lead-free. As manufacturers strive to produce smaller, more powerful devices, the need for reliable and efficient soldering solutions becomes increasingly important. In conclusion, both Lead Solder Balls and Lead-Free Solder Balls play a significant role in the Global Integrated Circuit Packaging Solder Ball Market, each offering unique advantages and challenges. The market continues to evolve as manufacturers balance the need for performance, reliability, and environmental compliance, driving innovation and growth in this critical segment of the electronics industry.

BGA, CSP & WLCSP, Flip-Chip & Others in the Global Integrated Circuit Packaging Solder Ball Market:

The Global Integrated Circuit Packaging Solder Ball Market finds extensive usage in various packaging technologies, including Ball Grid Array (BGA), Chip Scale Package (CSP) & Wafer Level Chip Scale Package (WLCSP), Flip-Chip, and others. In BGA applications, solder balls are used to create a grid of connections on the underside of the package, allowing for a higher density of connections compared to traditional pin-based packages. This configuration provides improved electrical performance and heat dissipation, making BGA a popular choice for high-performance applications such as processors and graphics cards. CSP and WLCSP technologies utilize solder balls to achieve a smaller package size, which is essential for modern electronic devices that demand compact and lightweight designs. These packaging methods allow for direct mounting of the die onto the PCB, reducing the overall footprint and improving signal integrity. The use of solder balls in CSP and WLCSP applications is critical for enabling the miniaturization of electronic devices, such as smartphones and wearable technology. Flip-Chip technology, on the other hand, involves mounting the die face-down onto the substrate, with solder balls providing the electrical connections. This method offers several advantages, including improved thermal performance and increased input/output (I/O) density, making it suitable for high-frequency and high-power applications. The use of solder balls in Flip-Chip packaging is essential for achieving the desired electrical and thermal performance, as well as ensuring the reliability of the connections. Other applications of solder balls in the Global Integrated Circuit Packaging Solder Ball Market include their use in multi-chip modules (MCMs) and system-in-package (SiP) solutions, where multiple dies are integrated into a single package. These advanced packaging technologies rely on solder balls to provide the necessary electrical connections and mechanical support, enabling the integration of diverse functionalities into a compact form factor. The versatility and reliability of solder balls make them indispensable in these applications, as they facilitate the development of innovative and high-performance electronic products. Overall, the usage of solder balls in BGA, CSP & WLCSP, Flip-Chip, and other packaging technologies underscores their critical role in the electronics industry. As devices continue to evolve and demand more advanced packaging solutions, the Global Integrated Circuit Packaging Solder Ball Market is poised to grow, driven by the need for reliable, efficient, and environmentally friendly soldering solutions.

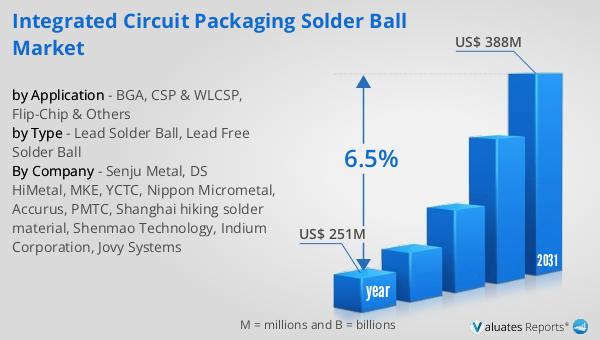

Global Integrated Circuit Packaging Solder Ball Market Outlook:

In 2024, the Global Integrated Circuit Packaging Solder Ball Market was valued at approximately US$ 251 million. This market is anticipated to expand significantly, reaching an estimated value of US$ 388 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.5% over the forecast period. The market's expansion is driven by the increasing demand for advanced electronic devices and the need for efficient and reliable packaging solutions. Companies like Senju Metal Accurus and DS HiMetal are key players in this market, collectively holding over 73% of the global market share. Their dominance is attributed to their extensive product offerings, technological expertise, and strong customer relationships. These companies continue to innovate and invest in research and development to maintain their competitive edge and meet the evolving needs of the electronics industry. The market outlook for the Global Integrated Circuit Packaging Solder Ball Market is promising, with opportunities for growth and innovation as manufacturers strive to develop more advanced and environmentally friendly soldering solutions. As the demand for miniaturized and high-performance electronic devices continues to rise, the market is expected to witness sustained growth, driven by technological advancements and the increasing adoption of lead-free solder balls.

| Report Metric | Details |

| Report Name | Integrated Circuit Packaging Solder Ball Market |

| Accounted market size in year | US$ 251 million |

| Forecasted market size in 2031 | US$ 388 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Senju Metal, DS HiMetal, MKE, YCTC, Nippon Micrometal, Accurus, PMTC, Shanghai hiking solder material, Shenmao Technology, Indium Corporation, Jovy Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |