What is Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market?

The Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market is a specialized segment within the broader semiconductor equipment industry. Electrostatic chucks are critical components used in semiconductor manufacturing processes, particularly in the handling and processing of wafers. The Johnsen-Rahbek type ESCs are known for their ability to securely hold wafers in place using electrostatic forces, which are generated by applying a voltage to the chuck. This technology is essential for ensuring precision and stability during various semiconductor fabrication processes. The market for these chucks is driven by the increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As the complexity and miniaturization of semiconductor devices continue to advance, the need for reliable and efficient wafer handling solutions like the JR type ESCs becomes even more critical. The market is characterized by a few key players who dominate the landscape, offering advanced solutions to meet the evolving needs of semiconductor manufacturers. The growth of this market is closely tied to the overall expansion of the semiconductor industry, which is fueled by technological advancements and the increasing integration of semiconductors in everyday devices.

CVD Equipment, PVD Equipment, IMP Equipment, ETCH Equipment, LITHO Equipment, Others in the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market:

In the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market, various types of equipment play a crucial role in semiconductor manufacturing. CVD (Chemical Vapor Deposition) equipment is used to deposit thin films on semiconductor wafers, a process essential for creating the layers that form integrated circuits. This equipment relies on JR type ESCs to hold the wafers securely during deposition, ensuring uniformity and precision. PVD (Physical Vapor Deposition) equipment, on the other hand, is used for coating wafers with thin films through physical processes like sputtering. The JR type ESCs are vital in maintaining wafer stability during these high-energy processes, preventing defects and ensuring high-quality coatings. IMP (Ion Metal Plasma) equipment is another critical component, used for depositing metal films on wafers. The electrostatic chucks in this equipment ensure that wafers remain in place during the ion bombardment process, which is crucial for achieving the desired film properties. ETCH equipment is used to remove material from the wafer surface, creating the intricate patterns needed for semiconductor devices. The precision and stability provided by JR type ESCs are essential in this process, as even minor deviations can lead to defects. LITHO equipment, used for photolithography, relies on these chucks to hold wafers steady during the exposure and development processes, ensuring that the patterns are transferred accurately. Other equipment types in this market include those used for cleaning, inspection, and testing, all of which benefit from the secure wafer handling provided by JR type ESCs. The integration of these chucks into various equipment types highlights their importance in the semiconductor manufacturing process, where precision and reliability are paramount.

Fab, Semiconductor Equipment Factory in the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market:

The usage of Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market in fabs and semiconductor equipment factories is integral to the production of semiconductor devices. In fabs, which are facilities where semiconductor devices are manufactured, JR type ESCs are used extensively across various stages of the production process. These chucks are essential for handling wafers during deposition, etching, and lithography processes, ensuring that the wafers remain stable and secure. This stability is crucial for achieving the high precision required in semiconductor manufacturing, where even the slightest movement can result in defects. The use of JR type ESCs in fabs helps to improve yield rates by reducing the likelihood of wafer damage and ensuring uniform processing. In semiconductor equipment factories, where the equipment used in fabs is manufactured, JR type ESCs are integrated into various machines to enhance their performance. These chucks are designed to meet the specific requirements of different equipment types, providing the necessary holding force and stability for each application. The use of JR type ESCs in equipment factories also contributes to the development of more advanced and efficient semiconductor manufacturing tools, which in turn supports the growth of the semiconductor industry. The integration of these chucks into both fabs and equipment factories underscores their importance in the semiconductor manufacturing ecosystem, where precision, reliability, and efficiency are key drivers of success.

Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market Outlook:

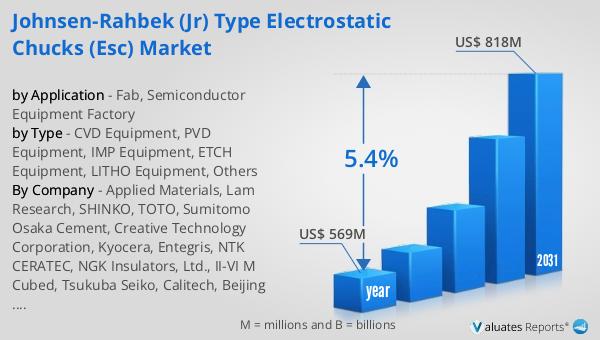

The outlook for the Global Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market indicates a promising trajectory. In 2024, the market was valued at approximately US$ 569 million, and it is anticipated to grow to a revised size of US$ 818 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. This growth is driven by the increasing demand for semiconductors across various industries and the need for advanced wafer handling solutions. Within this market, Applied Materials holds a dominant position, capturing a significant 43.84% of the revenue market share. Following closely is Lam Research, with a 31.58% revenue share, and SHINKO, which accounts for 10.21% of the market. These companies are key players in the industry, offering innovative solutions that cater to the evolving needs of semiconductor manufacturers. The competitive landscape of the JR type ESC market is shaped by the continuous advancements in semiconductor technology and the increasing complexity of semiconductor devices. As the market continues to expand, these companies are likely to play a pivotal role in driving innovation and meeting the growing demand for reliable and efficient wafer handling solutions.

| Report Metric | Details |

| Report Name | Johnsen-Rahbek (JR) Type Electrostatic Chucks (ESC) Market |

| Accounted market size in year | US$ 569 million |

| Forecasted market size in 2031 | US$ 818 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applied Materials, Lam Research, SHINKO, TOTO, Sumitomo Osaka Cement, Creative Technology Corporation, Kyocera, Entegris, NTK CERATEC, NGK Insulators, Ltd., II-VI M Cubed, Tsukuba Seiko, Calitech, Beijing U-PRECISION TECH CO., LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |