What is Global Paper Carrier Tape Market?

The Global Paper Carrier Tape Market is a specialized segment within the packaging industry, focusing on the production and distribution of paper carrier tapes. These tapes are primarily used in the electronics sector for the packaging of small electronic components such as semiconductors, resistors, capacitors, and inductors. The paper carrier tape serves as a medium to hold and transport these components safely during manufacturing and assembly processes. The market is driven by the increasing demand for electronic devices and the miniaturization of electronic components, which require precise and reliable packaging solutions. Paper carrier tapes are favored for their eco-friendly nature, cost-effectiveness, and ability to provide excellent protection to delicate components. The market is characterized by continuous innovation to improve the quality and functionality of the tapes, catering to the evolving needs of the electronics industry. As the demand for consumer electronics, automotive electronics, and industrial electronics continues to grow, the Global Paper Carrier Tape Market is expected to expand, offering numerous opportunities for manufacturers and suppliers in this niche sector. The market's growth is also supported by advancements in technology and the increasing adoption of automation in manufacturing processes.

Un-punched Paper Carrier Tape, Pre-punched Paper Carrier Tape, Others in the Global Paper Carrier Tape Market:

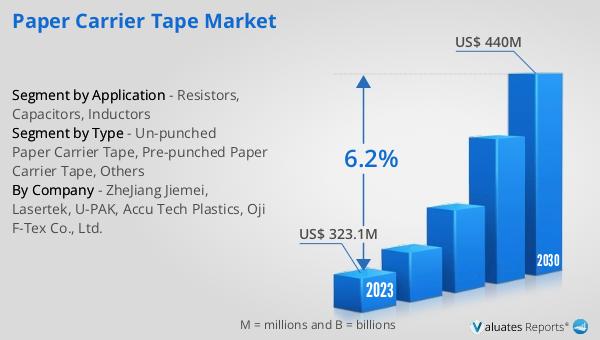

In the Global Paper Carrier Tape Market, there are different types of paper carrier tapes, each serving specific purposes based on the requirements of the electronic components they are designed to hold. Un-punched paper carrier tape is a type of tape that does not have pre-cut holes or cavities. This type of tape is typically used for components that do not require precise positioning or alignment during the packaging process. Un-punched tapes are often used in applications where the components are larger or where the exact placement is not critical. They offer flexibility in terms of customization, as manufacturers can punch the necessary holes or cavities according to their specific needs. This adaptability makes un-punched paper carrier tapes a versatile option for various packaging applications. On the other hand, pre-punched paper carrier tape comes with pre-cut holes or cavities that are specifically designed to hold and align electronic components accurately. This type of tape is essential for components that require precise positioning, such as small semiconductors, resistors, capacitors, and inductors. The pre-punched design ensures that each component is securely held in place, reducing the risk of damage during transportation and assembly. Pre-punched paper carrier tapes are widely used in automated manufacturing processes, where precision and efficiency are crucial. The use of pre-punched tapes helps streamline the production process, as it eliminates the need for additional punching or alignment steps, thereby saving time and reducing labor costs. Apart from un-punched and pre-punched paper carrier tapes, there are other variations available in the market to cater to specific needs. These may include tapes with different thicknesses, widths, and materials to accommodate various component sizes and weights. Some tapes are designed with anti-static properties to protect sensitive electronic components from electrostatic discharge, which can cause damage or malfunction. Additionally, there are tapes with enhanced durability and strength to withstand harsh environmental conditions or rough handling during transportation. The choice of paper carrier tape depends on several factors, including the type of components being packaged, the manufacturing process, and the end-use application. Manufacturers in the Global Paper Carrier Tape Market continuously innovate to develop new and improved tape solutions that meet the diverse needs of the electronics industry. The Global Paper Carrier Tape Market plays a crucial role in the packaging and transportation of electronic components such as resistors, capacitors, and inductors. These components are essential in the functioning of electronic devices, and their safe and efficient handling is vital to ensure the reliability and performance of the final products. Paper carrier tapes provide a secure and organized way to package these components, protecting them from damage during transportation and assembly. Resistors are one of the most common components used in electronic circuits, and they require precise packaging to maintain their integrity and functionality. Paper carrier tapes designed for resistors ensure that each component is held securely in place, preventing movement or damage during handling. The tapes also facilitate easy identification and retrieval of resistors during the assembly process, improving efficiency and reducing the risk of errors. The use of paper carrier tapes in packaging resistors is particularly important in automated manufacturing environments, where speed and accuracy are critical. Capacitors, like resistors, are widely used in electronic circuits and require careful handling to prevent damage. Paper carrier tapes provide a reliable packaging solution for capacitors, ensuring that they are protected from physical damage and environmental factors such as moisture and dust. The tapes also help maintain the alignment and orientation of capacitors, which is crucial for their proper functioning in electronic circuits. By using paper carrier tapes, manufacturers can ensure that capacitors are delivered to the assembly line in optimal condition, reducing the risk of defects and improving the overall quality of the final product. Inductors are another essential component in electronic circuits, and their packaging requires special consideration due to their unique shape and size. Paper carrier tapes designed for inductors provide a secure and organized way to package these components, ensuring that they are protected from damage during transportation and assembly. The tapes also help maintain the alignment and orientation of inductors, which is crucial for their proper functioning in electronic circuits. By using paper carrier tapes, manufacturers can ensure that inductors are delivered to the assembly line in optimal condition, reducing the risk of defects and improving the overall quality of the final product. The global market for paper carrier tape was valued at $324 million in 2024, and it is anticipated to grow significantly, reaching an estimated $490 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. The increasing demand for electronic devices and the miniaturization of electronic components are key factors driving this growth. As the electronics industry continues to evolve, the need for reliable and efficient packaging solutions like paper carrier tapes becomes more critical. These tapes offer several advantages, including cost-effectiveness, eco-friendliness, and the ability to provide excellent protection to delicate components. The market's expansion is also supported by advancements in technology and the increasing adoption of automation in manufacturing processes. As a result, manufacturers and suppliers in the Global Paper Carrier Tape Market are presented with numerous opportunities to innovate and develop new products that cater to the evolving needs of the electronics industry. The market's growth is expected to continue as the demand for consumer electronics, automotive electronics, and industrial electronics increases, driving the need for efficient and reliable packaging solutions.

Resistors, Capacitors, Inductors in the Global Paper Carrier Tape Market:

English: #PaperCarrierTape #ElectronicsPackaging #MarketGrowth #Resistors #Capacitors #Inductors #EcoFriendlyPackaging #Automation #Innovation #GlobalMarket

Global Paper Carrier Tape Market Outlook:

Japanese: #ペーパーキャリアテープ #電子機器包装 #市場成長 #抵抗器 #コンデンサ #インダクタ #エコフレンドリー包装 #自動化 #イノベーション #グローバル市場

| Report Metric | Details |

| Report Name | Paper Carrier Tape Market |

| Accounted market size in year | US$ 324 million |

| Forecasted market size in 2031 | US$ 490 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ZheJiang Jiemei, Lasertek, U-PAK, Accu Tech Plastics, Oji F-Tex Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |