What is Global Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brush Market?

The Global Chemical Mechanical Planarization (CMP) Polyvinyl Alcohol (PVA) Brush Market is an essential segment within the semiconductor manufacturing industry. CMP is a process used to smooth and flatten surfaces at a microscopic level, which is crucial for the production of semiconductor wafers. PVA brushes play a vital role in this process by ensuring that the surfaces are cleaned and polished effectively. These brushes are made from polyvinyl alcohol, a material known for its excellent absorbency and softness, which makes it ideal for delicate semiconductor surfaces. The market for these brushes is driven by the increasing demand for semiconductors in various applications, including electronics, automotive, and telecommunications. As technology advances, the need for more precise and efficient manufacturing processes grows, further boosting the demand for CMP PVA brushes. The market is characterized by continuous innovation, with manufacturers focusing on developing brushes that offer better performance and longer lifespans. Additionally, the market is influenced by the overall trends in the semiconductor industry, such as the shift towards smaller and more powerful devices, which require more advanced manufacturing techniques. Overall, the Global CMP PVA Brush Market is poised for growth as the semiconductor industry continues to expand and evolve.

Roll Shape, Sheet Shape in the Global Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brush Market:

In the Global Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brush Market, the roll shape and sheet shape are two primary forms that cater to different needs in the semiconductor manufacturing process. Roll-shaped PVA brushes are typically used in applications where continuous and uniform contact with the wafer surface is required. These brushes are designed to provide consistent pressure and coverage, ensuring that the entire surface is polished evenly. The roll shape allows for efficient cleaning and polishing, making it ideal for high-volume production environments. On the other hand, sheet-shaped PVA brushes are used in applications where more precise and controlled polishing is needed. These brushes are often employed in processes that require specific areas of the wafer to be targeted, allowing for greater flexibility and customization. The sheet shape provides the ability to apply varying levels of pressure and contact, which is crucial for achieving the desired surface finish. Both roll and sheet-shaped PVA brushes are essential in the CMP process, as they help to remove excess material, smooth out surface irregularities, and ensure that the wafers meet the stringent quality standards required in the semiconductor industry. The choice between roll and sheet shapes depends on the specific requirements of the manufacturing process, including the type of wafer being produced, the desired surface finish, and the production volume. Manufacturers in the CMP PVA Brush Market are continually innovating to improve the performance and durability of both roll and sheet-shaped brushes. This includes developing new materials and designs that enhance the brushes' ability to clean and polish effectively while minimizing wear and tear. Additionally, there is a growing focus on sustainability, with manufacturers exploring eco-friendly materials and production methods to reduce the environmental impact of their products. As the semiconductor industry continues to evolve, the demand for both roll and sheet-shaped PVA brushes is expected to grow, driven by the need for more advanced and efficient manufacturing processes. The market is also influenced by regional trends, with different regions exhibiting varying preferences for roll or sheet-shaped brushes based on their specific manufacturing needs and capabilities. Overall, the roll and sheet shapes in the Global CMP PVA Brush Market play a crucial role in the semiconductor manufacturing process, providing the necessary tools to achieve the high levels of precision and quality required in today's technology-driven world.

300 mm Wafer, 200 mm Wafer, Others in the Global Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brush Market:

The usage of Global Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brushes in the semiconductor industry is critical, particularly when dealing with different wafer sizes such as 300 mm, 200 mm, and others. For 300 mm wafers, which are the standard size in modern semiconductor manufacturing, PVA brushes are essential for achieving the high levels of precision and cleanliness required. These larger wafers allow for more chips to be produced per wafer, making the manufacturing process more efficient and cost-effective. PVA brushes help ensure that the surface of these wafers is smooth and free of defects, which is crucial for the performance and reliability of the final semiconductor products. The brushes are used in various stages of the CMP process, including the removal of excess material, polishing, and cleaning, to ensure that the wafers meet the stringent quality standards of the industry. For 200 mm wafers, which are still widely used in certain applications, PVA brushes play a similar role in ensuring surface quality and cleanliness. Although smaller than 300 mm wafers, 200 mm wafers are still an important part of the semiconductor manufacturing landscape, particularly for legacy technologies and specialized applications. The use of PVA brushes in the CMP process for 200 mm wafers helps maintain the necessary levels of precision and quality, ensuring that these wafers can be used effectively in various electronic devices. In addition to 300 mm and 200 mm wafers, PVA brushes are also used in the processing of other wafer sizes, including smaller and larger wafers that may be used for specific applications or experimental purposes. The versatility of PVA brushes makes them suitable for a wide range of wafer sizes and types, allowing manufacturers to achieve the desired surface finish and quality regardless of the specific requirements of the application. The use of PVA brushes in the CMP process is critical for ensuring that semiconductor wafers meet the high standards required for modern electronic devices. As the demand for semiconductors continues to grow, driven by advancements in technology and the increasing need for electronic devices, the importance of PVA brushes in the manufacturing process is expected to increase. Manufacturers are continually innovating to improve the performance and durability of PVA brushes, ensuring that they can meet the evolving needs of the semiconductor industry. Overall, the usage of PVA brushes in the CMP process is essential for achieving the high levels of precision and quality required in semiconductor manufacturing, regardless of the wafer size or application.

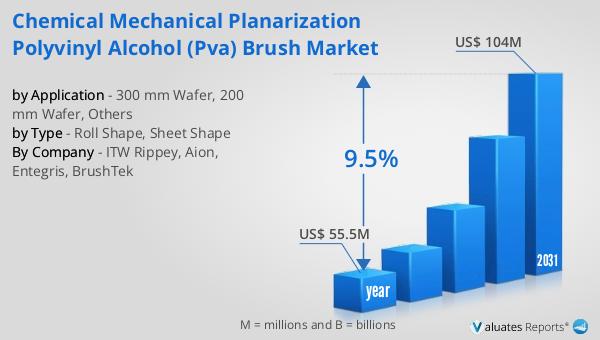

Global Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brush Market Outlook:

The global market for Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brushes was valued at $55.5 million in 2024 and is anticipated to grow to a revised size of $104 million by 2031, reflecting a compound annual growth rate (CAGR) of 9.5% during the forecast period. In the broader context, the semiconductor market was valued at $579 billion in 2022 and is projected to reach $790 billion by 2029, with a CAGR of 6% over the forecast period. The Asia-Pacific region, which is the largest market, experienced a decline of 2.0%. Meanwhile, sales in the Americas reached $142.1 billion, marking a 17.0% year-on-year increase. In Europe, sales were $53.8 billion, up 12.6% year-on-year, and in Japan, sales were $48.1 billion, reflecting a 10.0% year-on-year increase. However, the Asia-Pacific region, despite being the largest, saw sales of $336.2 billion, which was a 2.0% year-on-year decrease. These figures highlight the dynamic nature of the market, with varying growth rates across different regions. The growth in the Americas, Europe, and Japan indicates a strong demand for semiconductors, while the decline in the Asia-Pacific region suggests potential challenges or shifts in the market dynamics. Overall, the market outlook for CMP PVA Brushes and the semiconductor industry as a whole is characterized by growth opportunities and regional variations.

| Report Metric | Details |

| Report Name | Chemical Mechanical Planarization Polyvinyl Alcohol (PVA) Brush Market |

| Accounted market size in year | US$ 55.5 million |

| Forecasted market size in 2031 | US$ 104 million |

| CAGR | 9.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITW Rippey, Aion, Entegris, BrushTek |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |