What is Global Load Port Market?

The Global Load Port Market is a crucial component in the semiconductor manufacturing industry, serving as the interface between wafer handling systems and semiconductor processing equipment. Load ports are essential for the efficient transfer of semiconductor wafers into and out of processing tools, ensuring that the delicate wafers are handled with precision and care. These devices are designed to maintain a clean environment, preventing contamination that could compromise the quality of the semiconductor products. The market for load ports is driven by the increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As technology advances, the need for more sophisticated and efficient load port systems grows, leading to innovations in design and functionality. The global load port market is characterized by a range of products that cater to different needs, from basic manual systems to advanced automated solutions. Manufacturers in this market are focused on developing load ports that offer high reliability, speed, and compatibility with various wafer sizes and types. The market's growth is also influenced by the expansion of semiconductor manufacturing facilities worldwide, as companies strive to meet the rising demand for electronic devices.

Motor Drive Load Port, Air Drive Load Port in the Global Load Port Market:

Motor Drive Load Ports and Air Drive Load Ports are two significant types of load ports within the Global Load Port Market, each offering distinct advantages and applications. Motor Drive Load Ports are equipped with electric motors that facilitate the movement of wafers into and out of processing equipment. These load ports are known for their precision and ability to handle wafers with minimal human intervention, reducing the risk of contamination and damage. The motor-driven mechanism allows for smooth and controlled wafer transfer, making them ideal for high-volume production environments where speed and accuracy are paramount. Motor Drive Load Ports are often used in advanced semiconductor manufacturing facilities that require high throughput and reliability. On the other hand, Air Drive Load Ports utilize pneumatic systems to move wafers. These load ports are favored for their simplicity and cost-effectiveness, as they rely on compressed air to operate. Air Drive Load Ports are typically used in environments where the cost of operation is a significant consideration, and where the production volume may not justify the investment in more complex motor-driven systems. Despite their simplicity, Air Drive Load Ports are capable of providing reliable wafer handling, making them suitable for a variety of applications. Both types of load ports are designed to integrate seamlessly with other semiconductor manufacturing equipment, ensuring a smooth and efficient production process. The choice between Motor Drive and Air Drive Load Ports often depends on the specific requirements of the manufacturing facility, including factors such as production volume, budget, and the level of automation desired. As the semiconductor industry continues to evolve, manufacturers are constantly innovating to improve the performance and capabilities of both Motor Drive and Air Drive Load Ports, ensuring they meet the ever-changing needs of the market.

EFEM, Sorters in the Global Load Port Market:

The Global Load Port Market plays a vital role in the operation of EFEM (Equipment Front End Module) and Sorters, two critical components in semiconductor manufacturing. EFEMs are automated systems that serve as the interface between the cleanroom environment and the processing equipment, ensuring that wafers are transferred safely and efficiently. Load ports are an integral part of EFEMs, providing the necessary interface for wafer transfer. They ensure that wafers are loaded and unloaded with precision, maintaining the cleanliness and integrity of the wafers throughout the process. The use of load ports in EFEMs is essential for maintaining the high standards of cleanliness required in semiconductor manufacturing, as even the smallest contamination can lead to defects in the final product. Sorters, on the other hand, are used to organize and manage wafers as they move through the manufacturing process. Load ports in sorters facilitate the efficient transfer of wafers between different stages of production, ensuring that they are processed in the correct order and without delay. The integration of load ports in sorters helps to streamline the manufacturing process, reducing the risk of errors and improving overall efficiency. In both EFEMs and sorters, load ports are designed to handle wafers with care, minimizing the risk of damage and ensuring that they are processed to the highest standards. The use of load ports in these applications is critical for maintaining the quality and reliability of semiconductor products, as they ensure that wafers are handled with the utmost precision and care. As the demand for semiconductors continues to grow, the role of load ports in EFEMs and sorters becomes increasingly important, driving innovation and development in the Global Load Port Market.

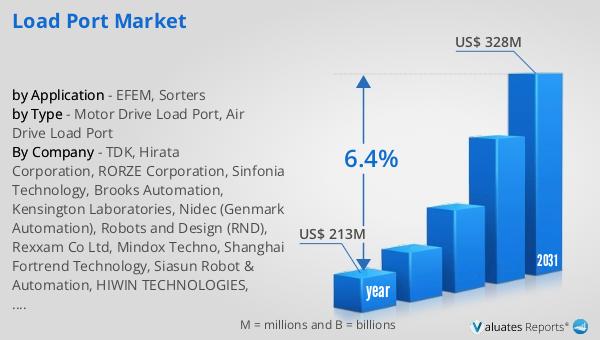

Global Load Port Market Outlook:

In 2024, the Global Load Port Market was valued at approximately $213 million, with projections indicating a growth to around $328 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. Key players in the EFEM and Sorters market include Brooks Automation, RORZE Corporation, Hirata Corporation, Cymechs Inc, and Sinfonia Technology, among others. In 2021, the top four global players held a significant share of about 69% in terms of revenue. Specifically, for EFEM, major players such as RORZE, Brooks Automation, Hirata, Cymechs, and Siasun Robot Automation dominate the market, with the top five players commanding over 90% of the market share. In the Sorters segment, leading companies like Hirata Corporation, RORZE, JEL Corporation, and Brooks Automation hold more than 50% of the market share. The semiconductor market, a key driver for load ports, was estimated at $526.8 billion in 2023 and is expected to reach $780.7 billion by 2030. Furthermore, the semiconductor manufacturing wafer fabrication market is projected to grow from $251.7 billion in 2023 to $506.5 billion by 2030, with a remarkable CAGR of 40.49% during the forecast period.

| Report Metric | Details |

| Report Name | Load Port Market |

| Accounted market size in year | US$ 213 million |

| Forecasted market size in 2031 | US$ 328 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TDK, Hirata Corporation, RORZE Corporation, Sinfonia Technology, Brooks Automation, Kensington Laboratories, Nidec (Genmark Automation), Robots and Design (RND), Rexxam Co Ltd, Mindox Techno, Shanghai Fortrend Technology, Siasun Robot & Automation, HIWIN TECHNOLOGIES, Sanwa Engineering Corporation, Huaxin (Jiaxing) Intelligent Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |