What is Global Rotary Gripper Module Market?

The Global Rotary Gripper Module Market is a specialized segment within the broader automation and robotics industry, focusing on devices that combine rotary and gripping functions. These modules are essential in various industrial applications, providing the ability to pick, rotate, and place objects with precision and efficiency. They are widely used in manufacturing processes, where automation is key to improving productivity and reducing labor costs. The market for these modules is driven by the increasing demand for automation in industries such as automotive, electronics, and packaging. As industries strive for higher efficiency and precision, the need for advanced gripper modules that can handle complex tasks with ease is growing. These modules are designed to handle a wide range of materials and sizes, making them versatile tools in automated systems. The market is characterized by continuous innovation, with manufacturers focusing on developing modules that offer higher speed, accuracy, and flexibility. As a result, the Global Rotary Gripper Module Market is poised for steady growth, driven by technological advancements and the increasing adoption of automation across various industries.

Parallel, Angular in the Global Rotary Gripper Module Market:

In the Global Rotary Gripper Module Market, two primary types of grippers are prevalent: parallel and angular. Parallel grippers are designed to open and close in a linear motion, with the jaws moving parallel to each other. This design is particularly useful for handling objects with consistent shapes and sizes, such as boxes or cylindrical components. Parallel grippers are known for their precision and ability to exert uniform pressure, making them ideal for applications where delicate handling is required. They are commonly used in industries like electronics, where small and fragile components need to be handled with care. On the other hand, angular grippers operate with a pivoting motion, where the jaws open and close at an angle. This design allows for a wider range of motion and is suitable for handling irregularly shaped objects. Angular grippers are often used in applications where the object needs to be gripped from the side or where space constraints require a more compact gripper design. They are popular in the automotive industry, where components of varying shapes and sizes need to be manipulated. Both parallel and angular grippers are integral to the functionality of rotary gripper modules, providing the versatility needed to handle diverse tasks in automated systems. The choice between parallel and angular grippers depends on the specific requirements of the application, such as the shape and size of the objects being handled, the required precision, and the available space. Manufacturers in the Global Rotary Gripper Module Market are continually innovating to enhance the capabilities of both types of grippers, focusing on improving their speed, accuracy, and adaptability. This innovation is driven by the need to meet the evolving demands of industries that are increasingly relying on automation to improve efficiency and reduce costs. As a result, the market for parallel and angular grippers is expected to grow, supported by advancements in technology and the expanding adoption of automation across various sectors.

For Assemblies, For Clean Rooms, For Work Piece Handling, Others in the Global Rotary Gripper Module Market:

The Global Rotary Gripper Module Market finds extensive usage in several key areas, including assemblies, clean rooms, workpiece handling, and other specialized applications. In assembly operations, rotary gripper modules play a crucial role by automating the process of picking, rotating, and placing components. This automation not only speeds up the assembly process but also enhances precision and consistency, which are vital in industries such as automotive and electronics. The ability to handle components with varying shapes and sizes makes these modules indispensable in complex assembly lines. In clean rooms, where maintaining a contaminant-free environment is critical, rotary gripper modules are designed to operate without generating particles or contaminants. These modules are essential in industries like pharmaceuticals and semiconductors, where even the slightest contamination can lead to significant product defects. The use of rotary gripper modules in clean rooms ensures that delicate processes are carried out with the highest level of cleanliness and precision. For workpiece handling, rotary gripper modules provide the flexibility needed to manipulate objects of different sizes and shapes. This capability is particularly important in manufacturing environments where components need to be moved, rotated, and positioned accurately. The use of these modules in workpiece handling not only improves efficiency but also reduces the risk of damage to the components, ensuring high-quality output. Beyond these applications, rotary gripper modules are also used in other specialized areas, such as packaging and material handling. In packaging, these modules automate the process of picking and placing products into containers, streamlining operations and reducing labor costs. In material handling, rotary gripper modules facilitate the movement of materials within a facility, enhancing workflow and productivity. The versatility and adaptability of rotary gripper modules make them valuable tools in a wide range of industrial applications, driving their demand in the Global Rotary Gripper Module Market.

Global Rotary Gripper Module Market Outlook:

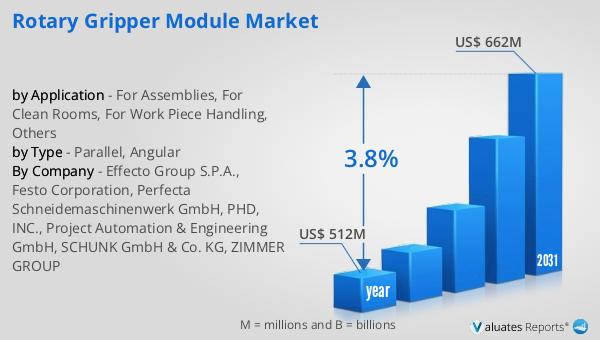

The global market for Rotary Gripper Modules was valued at $512 million in 2024, and it is anticipated to grow to a revised size of $662 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.8% over the forecast period. This growth trajectory underscores the increasing demand for automation solutions across various industries. As businesses strive to enhance operational efficiency and reduce costs, the adoption of advanced automation technologies, such as rotary gripper modules, is becoming more prevalent. These modules offer the dual functionality of gripping and rotating, making them indispensable in modern manufacturing and assembly processes. The projected growth in the market is driven by the need for precision and speed in industrial operations, as well as the ongoing advancements in technology that enhance the capabilities of these modules. The steady increase in market value highlights the importance of rotary gripper modules in the automation landscape, as industries continue to seek innovative solutions to meet their evolving needs. As the market expands, manufacturers are likely to focus on developing more sophisticated and versatile modules to cater to the diverse requirements of different sectors. This growth not only reflects the rising demand for automation but also the continuous innovation and development within the Global Rotary Gripper Module Market.

| Report Metric | Details |

| Report Name | Rotary Gripper Module Market |

| Accounted market size in year | US$ 512 million |

| Forecasted market size in 2031 | US$ 662 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Effecto Group S.P.A., Festo Corporation, Perfecta Schneidemaschinenwerk GmbH, PHD, INC., Project Automation & Engineering GmbH, SCHUNK GmbH & Co. KG, ZIMMER GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |