What is Global Spray Foam Equipment Market?

The Global Spray Foam Equipment Market is a dynamic and evolving sector that plays a crucial role in various industries by providing essential tools for insulation and sealing applications. Spray foam equipment is used to apply polyurethane foam, which expands and hardens upon application, creating an effective barrier against air, moisture, and temperature fluctuations. This market encompasses a wide range of equipment, including spray guns, proportioners, and other accessories, designed to handle different types of foam and application needs. The demand for spray foam equipment is driven by the growing emphasis on energy efficiency and sustainable building practices, as spray foam insulation is known for its superior insulating properties compared to traditional materials. Additionally, the market is influenced by advancements in technology that enhance the precision and efficiency of spray foam application, making it more accessible and appealing to a broader range of users. As industries continue to prioritize energy conservation and environmental sustainability, the Global Spray Foam Equipment Market is expected to witness steady growth, driven by innovations and increasing adoption across various sectors.

Low Pressure Spray Foam Equipment, High Pressure Spray Foam Equipment in the Global Spray Foam Equipment Market:

Low Pressure Spray Foam Equipment and High Pressure Spray Foam Equipment are two primary categories within the Global Spray Foam Equipment Market, each serving distinct purposes and applications. Low Pressure Spray Foam Equipment is typically used for smaller projects and repairs, where precision and ease of use are paramount. This type of equipment is ideal for residential applications, such as sealing gaps and cracks in homes, as well as for smaller commercial projects. Low pressure systems are generally more user-friendly, requiring less training and expertise to operate, making them accessible to a wider range of users, including DIY enthusiasts and small contractors. They are often portable and cost-effective, providing a practical solution for projects that do not require the high output and speed of high pressure systems. On the other hand, High Pressure Spray Foam Equipment is designed for larger scale projects and industrial applications, where speed, efficiency, and coverage are critical. This equipment is capable of delivering a higher volume of foam at a faster rate, making it suitable for large commercial buildings, industrial facilities, and extensive residential developments. High pressure systems require more specialized training and expertise to operate, as they involve more complex machinery and higher safety considerations. These systems are often used by professional contractors and companies specializing in insulation and large-scale construction projects. The choice between low pressure and high pressure equipment depends on the specific needs of the project, including the size, scope, and desired outcome. Both types of equipment have their own advantages and limitations, and the decision often involves balancing factors such as cost, efficiency, and ease of use. As the Global Spray Foam Equipment Market continues to grow, advancements in technology are likely to further enhance the capabilities and accessibility of both low pressure and high pressure systems, catering to a diverse range of applications and user needs.

Automotive, Electrical Appliance, Construction, Others in the Global Spray Foam Equipment Market:

The Global Spray Foam Equipment Market finds extensive usage across various sectors, including automotive, electrical appliances, construction, and others, each benefiting from the unique properties of spray foam insulation. In the automotive industry, spray foam equipment is used to enhance vehicle insulation, providing better temperature control and noise reduction. This application is particularly important in electric vehicles, where maintaining optimal battery temperature is crucial for performance and longevity. Spray foam also contributes to the structural integrity of vehicles by filling gaps and reinforcing panels, leading to improved safety and durability. In the realm of electrical appliances, spray foam equipment is employed to insulate components, ensuring energy efficiency and reducing heat loss. This is especially relevant in appliances like refrigerators and freezers, where maintaining consistent internal temperatures is essential for performance and energy conservation. The construction industry is one of the largest consumers of spray foam equipment, utilizing it for insulation in residential, commercial, and industrial buildings. Spray foam insulation provides superior thermal resistance, reducing energy consumption and enhancing indoor comfort. It also acts as a barrier against moisture and air infiltration, preventing mold growth and improving indoor air quality. Additionally, spray foam is used in roofing applications, providing a seamless and durable protective layer that extends the lifespan of roofs. Beyond these sectors, spray foam equipment is also used in various other applications, such as marine and aerospace industries, where lightweight and efficient insulation is required. The versatility and effectiveness of spray foam make it a valuable tool in numerous industries, driving the demand for advanced equipment that can meet diverse application needs. As the focus on energy efficiency and sustainability continues to grow, the Global Spray Foam Equipment Market is poised to expand, with innovations and technological advancements further enhancing its capabilities and applications.

Global Spray Foam Equipment Market Outlook:

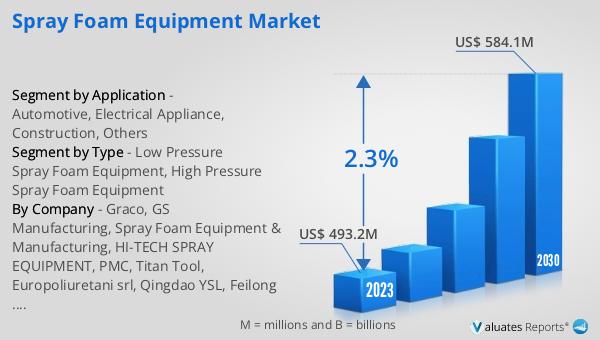

In 2024, the global market for Spray Foam Equipment was valued at approximately $521 million. Looking ahead, it is anticipated to grow to a revised size of around $608 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.3% over the forecast period. This growth trajectory underscores the increasing demand for spray foam equipment across various industries, driven by the need for energy-efficient and sustainable solutions. Notably, the market is characterized by a significant concentration of power among the leading manufacturers, with the top two companies holding a combined market share of over 50%. This dominance highlights the competitive landscape of the industry, where innovation and technological advancements play a crucial role in maintaining market leadership. As the market continues to evolve, companies are likely to focus on expanding their product portfolios and enhancing their distribution networks to capture a larger share of the growing demand. The projected growth of the Global Spray Foam Equipment Market reflects the broader trends towards energy conservation and environmental sustainability, as industries increasingly adopt spray foam insulation for its superior performance and efficiency.

| Report Metric | Details |

| Report Name | Spray Foam Equipment Market |

| Accounted market size in year | US$ 521 million |

| Forecasted market size in 2031 | US$ 608 million |

| CAGR | 2.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Graco, GS Manufacturing, Spray Foam Equipment & Manufacturing, HI-TECH SPRAY EQUIPMENT, PMC, Titan Tool, Europoliuretani srl, Qingdao YSL, Feilong Polyrethane Equipment Engineering, Dongguan Qifu Machine Equipment, Ruian Taike, Zhejiang Lingxin Polyuretane |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |