What is Global Specialty Carbon Blacks for Plastics Market?

Global Specialty Carbon Blacks for Plastics Market refers to a segment within the broader carbon black industry that focuses on producing high-performance carbon blacks specifically designed for use in plastic applications. These specialty carbon blacks are engineered to enhance the properties of plastics, such as improving their color, conductivity, UV protection, and mechanical strength. Unlike standard carbon blacks, which are primarily used for reinforcing rubber in tires, specialty carbon blacks are tailored to meet the specific needs of the plastics industry. They are used in a wide range of plastic products, from automotive components to consumer electronics, providing essential attributes that enhance the performance and longevity of these products. The market for these specialty carbon blacks is driven by the growing demand for high-quality plastics in various industries, including automotive, electronics, and consumer goods. As manufacturers seek to develop more durable and efficient plastic products, the demand for specialty carbon blacks continues to rise, making it a vital component in the global plastics market. The market is characterized by continuous innovation and development, as producers strive to create carbon blacks that meet the evolving needs of the plastics industry.

Lamp Black, Acetylene Black, Gas Black, Other Types in the Global Specialty Carbon Blacks for Plastics Market:

Lamp Black, Acetylene Black, Gas Black, and other types of carbon blacks play a crucial role in the Global Specialty Carbon Blacks for Plastics Market. Lamp Black is one of the oldest forms of carbon black, traditionally produced by burning oil or tar in a limited supply of air. It is known for its deep black color and is often used in applications where color intensity is a priority. However, its structure and properties may not be as refined as other types, making it less suitable for applications requiring high conductivity or specific mechanical properties. Acetylene Black, on the other hand, is produced by the thermal decomposition of acetylene gas. This type of carbon black is highly pure and has excellent electrical conductivity, making it ideal for applications in electronics and conductive plastics. Its unique structure provides superior performance in terms of conductivity and dispersion, which is why it is often used in high-end electronic applications and specialty plastic products that require enhanced electrical properties. Gas Black is produced by the incomplete combustion of natural gas. It is characterized by its fine particle size and high surface area, which contribute to its excellent dispersion properties in plastics. Gas Black is often used in applications where a smooth surface finish and uniform color are essential, such as in automotive parts and consumer electronics. Its ability to provide a consistent color and finish makes it a popular choice in the plastics industry. Other types of carbon blacks, such as thermal black and furnace black, also contribute to the specialty carbon blacks market. These types are produced through different processes and offer varying properties that can be tailored to specific applications. For instance, thermal black is known for its large particle size and low structure, making it suitable for applications requiring low reinforcement and high resilience. Furnace black, produced by the incomplete combustion of hydrocarbons, is versatile and can be engineered to provide a range of properties, from high reinforcement to excellent UV protection. Each type of carbon black offers unique characteristics that can be leveraged to enhance the performance of plastic products. The choice of carbon black type depends on the specific requirements of the application, such as color, conductivity, UV resistance, and mechanical properties. As the demand for high-performance plastics continues to grow, the role of these specialty carbon blacks becomes increasingly important. Manufacturers are constantly innovating to develop new types of carbon blacks that meet the evolving needs of the plastics industry, ensuring that they remain competitive in a rapidly changing market. The diversity of carbon black types available allows for a wide range of applications, from automotive and electronics to consumer goods and industrial parts, highlighting the versatility and importance of specialty carbon blacks in the global plastics market.

Automobile, Electrical Engineering&Electronics, Consumer Products, Industrial Parts in the Global Specialty Carbon Blacks for Plastics Market:

The usage of Global Specialty Carbon Blacks for Plastics Market spans several key areas, including the automobile, electrical engineering and electronics, consumer products, and industrial parts sectors. In the automobile industry, specialty carbon blacks are used to enhance the performance and aesthetics of various plastic components. They provide essential properties such as UV protection, color stability, and mechanical strength, which are crucial for automotive parts exposed to harsh environmental conditions. For instance, carbon blacks are used in the production of bumpers, dashboards, and interior trims, where they help maintain the appearance and durability of these components over time. In the field of electrical engineering and electronics, specialty carbon blacks are valued for their conductive properties. They are used in the production of conductive plastics, which are essential for manufacturing electronic components such as connectors, cables, and housings. The ability of carbon blacks to improve the electrical conductivity of plastics makes them indispensable in the electronics industry, where reliable performance and safety are paramount. In consumer products, specialty carbon blacks are used to enhance the appearance and functionality of a wide range of plastic goods. From packaging materials to household appliances, carbon blacks provide the deep black color and UV resistance needed to ensure that these products remain attractive and durable throughout their lifecycle. The use of carbon blacks in consumer products also extends to personal care items, where they are used to improve the texture and appearance of packaging materials. In the industrial parts sector, specialty carbon blacks are used to improve the mechanical properties of plastic components used in various industrial applications. They provide the reinforcement needed to enhance the strength and resilience of plastic parts, making them suitable for use in demanding environments. For example, carbon blacks are used in the production of pipes, fittings, and other industrial components that require high durability and resistance to wear and tear. The versatility of specialty carbon blacks allows them to be used in a wide range of applications, making them an essential component in the global plastics market. As industries continue to demand high-performance plastics, the role of specialty carbon blacks in enhancing the properties of these materials becomes increasingly important. Manufacturers are constantly seeking new ways to leverage the unique properties of carbon blacks to develop innovative plastic products that meet the evolving needs of various industries.

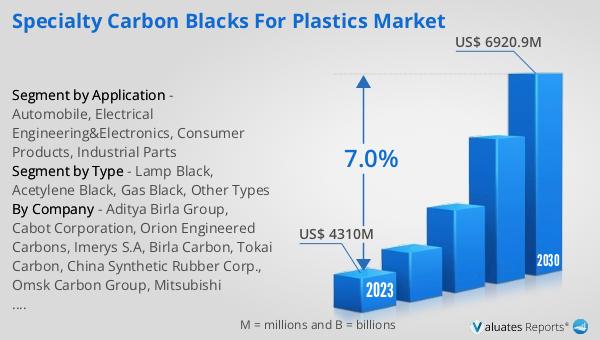

Global Specialty Carbon Blacks for Plastics Market Outlook:

The global market for Specialty Carbon Blacks for Plastics was valued at $4,902 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $7,820 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 7.0% over the forecast period. This upward trend is indicative of the increasing demand for high-performance plastics across various industries, including automotive, electronics, and consumer goods. The market's expansion is driven by the need for plastics that offer enhanced properties such as improved color, conductivity, and UV protection. As manufacturers strive to develop more durable and efficient plastic products, the demand for specialty carbon blacks continues to rise. This growth is also fueled by technological advancements and innovations in the production of carbon blacks, which enable manufacturers to create products that meet the specific needs of the plastics industry. The market's robust growth prospects highlight the importance of specialty carbon blacks as a key component in the global plastics market. As the industry continues to evolve, the role of specialty carbon blacks in enhancing the performance and longevity of plastic products becomes increasingly critical. The market's growth is a testament to the ongoing efforts of manufacturers to innovate and develop new types of carbon blacks that cater to the diverse needs of the plastics industry.

| Report Metric | Details |

| Report Name | Specialty Carbon Blacks for Plastics Market |

| Accounted market size in year | US$ 4902 million |

| Forecasted market size in 2031 | US$ 7820 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aditya Birla Group, Cabot Corporation, Orion Engineered Carbons, Imerys S.A, Birla Carbon, Tokai Carbon, China Synthetic Rubber Corp., Omsk Carbon Group, Mitsubishi Chemical, Denka Company, Himadri Speciality Chemical Limited, Continental Carbon, RP-Sanjiv Goenka Group(PCBL), PentaCarbon GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |