What is Global PVDF Lithium Ion Batteries Binders Market?

The Global PVDF Lithium Ion Batteries Binders Market is a specialized segment within the broader lithium-ion battery industry, focusing on the use of polyvinylidene fluoride (PVDF) as a binder material. PVDF is a highly non-reactive and pure thermoplastic fluoropolymer, which is used in various applications due to its excellent chemical resistance, thermal stability, and mechanical properties. In the context of lithium-ion batteries, binders are crucial as they hold the active material particles together and adhere them to the current collectors. This ensures the structural integrity and efficiency of the battery. The demand for PVDF binders is driven by the increasing production of lithium-ion batteries, which are essential for powering a wide range of devices from smartphones to electric vehicles. As the world shifts towards renewable energy and electric mobility, the need for efficient and reliable energy storage solutions like lithium-ion batteries is growing, thereby boosting the market for PVDF binders. The market is characterized by technological advancements and innovations aimed at improving battery performance, lifespan, and safety.

Emulsion Polymerization, Suspension Polymerization in the Global PVDF Lithium Ion Batteries Binders Market:

Emulsion polymerization and suspension polymerization are two key processes used in the production of PVDF binders for lithium-ion batteries, each with its own set of advantages and applications. Emulsion polymerization is a process where the monomer is emulsified with water and a surfactant, creating a stable emulsion. This method is known for producing polymers with high molecular weight and uniform particle size, which are essential for the consistent performance of lithium-ion batteries. The process involves the polymerization of the monomer droplets within the emulsion, resulting in a latex product that can be easily processed into films or coatings. This method is particularly advantageous for producing PVDF binders as it allows for better control over the polymer's properties, such as its crystallinity and thermal stability, which are crucial for the performance of lithium-ion batteries. On the other hand, suspension polymerization involves the polymerization of monomer droplets suspended in a continuous phase, usually water. This process is similar to emulsion polymerization but differs in the size of the monomer droplets and the absence of surfactants. Suspension polymerization typically results in larger polymer particles, which can be beneficial for certain applications where a higher degree of porosity is required. This method is often used for producing PVDF binders with specific properties tailored to the needs of different battery applications. Both emulsion and suspension polymerization processes are integral to the production of PVDF binders, each offering unique benefits that cater to the diverse requirements of the lithium-ion battery market. The choice between these two methods depends on various factors, including the desired properties of the final product, the specific application, and the production costs. As the demand for lithium-ion batteries continues to rise, driven by the increasing adoption of electric vehicles and renewable energy storage solutions, the importance of efficient and reliable binder materials like PVDF is becoming more pronounced. Manufacturers are continuously exploring new techniques and innovations in polymerization processes to enhance the performance and sustainability of PVDF binders, ensuring they meet the evolving needs of the global market.

Digital Battery, Energy Storage Battery, Power Battery in the Global PVDF Lithium Ion Batteries Binders Market:

The usage of Global PVDF Lithium Ion Batteries Binders Market extends across various applications, including digital batteries, energy storage batteries, and power batteries, each with its unique requirements and challenges. In digital batteries, which power devices like smartphones, laptops, and tablets, PVDF binders play a crucial role in ensuring the compactness and efficiency of the battery. These devices require batteries that are not only lightweight and compact but also capable of delivering high energy density and long cycle life. PVDF binders contribute to these requirements by providing excellent adhesion and mechanical stability, which are essential for maintaining the structural integrity of the battery during repeated charge and discharge cycles. In energy storage batteries, which are used for storing energy from renewable sources like solar and wind, PVDF binders are critical for ensuring the long-term stability and efficiency of the battery. These batteries need to store large amounts of energy and deliver it reliably over extended periods, making the performance and durability of the binder material crucial. PVDF binders offer excellent chemical resistance and thermal stability, which help in maintaining the performance of the battery under varying environmental conditions. In power batteries, which are used in electric vehicles and other high-power applications, PVDF binders are essential for ensuring the safety and performance of the battery. These applications require batteries that can deliver high power output and withstand high temperatures and mechanical stresses. PVDF binders provide the necessary mechanical strength and thermal stability, ensuring the battery can operate safely and efficiently under demanding conditions. The versatility and performance of PVDF binders make them an ideal choice for a wide range of lithium-ion battery applications, contributing to the growth and development of the global PVDF Lithium Ion Batteries Binders Market.

Global PVDF Lithium Ion Batteries Binders Market Outlook:

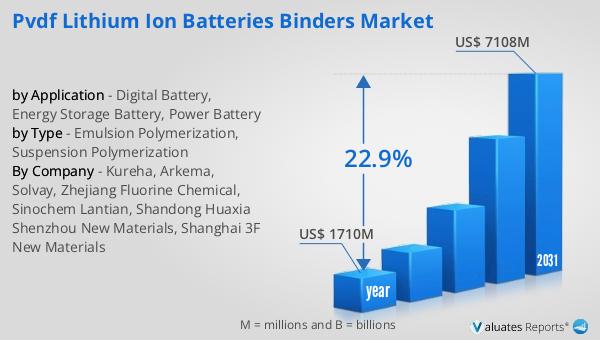

The global market for PVDF Lithium Ion Batteries Binders was valued at approximately $1.71 billion in 2024, and it is anticipated to expand significantly, reaching an estimated size of $7.108 billion by 2031. This growth represents a robust compound annual growth rate (CAGR) of 22.9% over the forecast period. The market is dominated by the top three manufacturers, who collectively hold a substantial share exceeding 70%. This indicates a highly competitive landscape where a few key players have significant influence over market trends and pricing. In terms of product segmentation, emulsion polymerization emerges as the largest segment, accounting for more than 50% of the market share. This dominance can be attributed to the advantages offered by emulsion polymerization, such as the production of high molecular weight polymers with uniform particle size, which are crucial for the performance of lithium-ion batteries. The strong growth trajectory of the PVDF Lithium Ion Batteries Binders Market is driven by the increasing demand for lithium-ion batteries across various applications, including consumer electronics, electric vehicles, and renewable energy storage. As the world continues to transition towards cleaner energy solutions and electric mobility, the need for efficient and reliable energy storage solutions like lithium-ion batteries is expected to rise, further propelling the demand for PVDF binders. The market is also characterized by ongoing technological advancements and innovations aimed at improving the performance, safety, and sustainability of PVDF binders, ensuring they meet the evolving needs of the global market.

| Report Metric | Details |

| Report Name | PVDF Lithium Ion Batteries Binders Market |

| Accounted market size in year | US$ 1710 million |

| Forecasted market size in 2031 | US$ 7108 million |

| CAGR | 22.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kureha, Arkema, Solvay, Zhejiang Fluorine Chemical, Sinochem Lantian, Shandong Huaxia Shenzhou New Materials, Shanghai 3F New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |