What is Global Powder Metal Magnetic Materials Market?

The Global Powder Metal Magnetic Materials Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries. These materials are primarily used in the production of components that require magnetic properties, such as motors, transformers, and sensors. Powder metal magnetic materials are created by compacting and sintering metal powders, which allows for precise control over their magnetic characteristics. This market is driven by the increasing demand for energy-efficient and high-performance magnetic components, particularly in the automotive and electronics industries. As technology advances, the need for smaller, lighter, and more efficient magnetic materials continues to grow, further propelling the market. Additionally, the shift towards renewable energy sources and the electrification of vehicles are significant factors contributing to the expansion of this market. The global reach of this market is evident, with key players and manufacturers spread across North America, Europe, and Asia-Pacific, each contributing to the development and innovation of powder metal magnetic materials. The market's growth is also supported by ongoing research and development efforts aimed at enhancing the properties and applications of these materials, ensuring they meet the evolving needs of various industries.

Sintered (For DC or DC Applications), Soft Magnetic Composite Type (For AC or AC Applications) in the Global Powder Metal Magnetic Materials Market:

Sintered powder metal magnetic materials, primarily used for DC or direct current applications, are a cornerstone of the Global Powder Metal Magnetic Materials Market. These materials are produced through a process that involves compacting metal powders into a desired shape and then heating them to a temperature below their melting point, a technique known as sintering. This process results in a solid piece with enhanced magnetic properties, making it ideal for applications that require stable and consistent magnetic performance. Sintered materials are particularly valued for their high density and strength, which contribute to their durability and efficiency in DC applications. They are commonly used in the production of components such as DC motors, generators, and transformers, where they help improve energy efficiency and performance. The ability to tailor the magnetic properties of sintered materials through the selection of specific metal powders and sintering conditions allows manufacturers to meet the precise requirements of various applications. On the other hand, Soft Magnetic Composite (SMC) materials are designed for AC or alternating current applications. These materials are composed of ferromagnetic powders coated with an insulating layer, which are then compacted into a desired shape. The insulating layer helps reduce eddy current losses, making SMC materials highly efficient for AC applications. They are particularly useful in the production of components such as AC motors, inductors, and transformers, where they contribute to improved energy efficiency and performance. The use of SMC materials allows for the design of complex shapes and geometries, enabling the production of compact and lightweight components. This is particularly advantageous in industries such as automotive and electronics, where space and weight are critical considerations. The Global Powder Metal Magnetic Materials Market is witnessing significant growth due to the increasing demand for both sintered and SMC materials. The automotive industry, in particular, is a major driver of this growth, as manufacturers seek to develop more efficient and environmentally friendly vehicles. The shift towards electric and hybrid vehicles is creating a demand for advanced magnetic materials that can enhance the performance of electric motors and other components. Similarly, the electronics industry is experiencing a surge in demand for compact and efficient magnetic components, driven by the proliferation of smart devices and the Internet of Things (IoT). The ability to produce high-performance magnetic materials with precise properties is a key factor in meeting the needs of these industries. Furthermore, ongoing research and development efforts are focused on improving the properties and applications of both sintered and SMC materials. Innovations in material composition, manufacturing processes, and design techniques are enabling the production of magnetic materials with enhanced performance and efficiency. These advancements are expected to further drive the growth of the Global Powder Metal Magnetic Materials Market, as industries continue to seek out new and improved solutions for their magnetic component needs. The market's expansion is also supported by the increasing adoption of renewable energy sources, which require efficient and reliable magnetic materials for the production of wind turbines, solar panels, and other energy generation systems. As the demand for clean and sustainable energy continues to rise, the need for advanced magnetic materials is expected to grow, further fueling the market's growth. Overall, the Global Powder Metal Magnetic Materials Market is poised for significant expansion, driven by the increasing demand for high-performance magnetic components across various industries.

Solenoids, DC Rotor and Stator, Brushless DC Motor Rotor in the Global Powder Metal Magnetic Materials Market:

The Global Powder Metal Magnetic Materials Market finds extensive usage in various applications, including solenoids, DC rotors and stators, and brushless DC motor rotors. Solenoids, which are electromagnetic devices used to convert electrical energy into mechanical motion, rely heavily on powder metal magnetic materials for their core components. These materials provide the necessary magnetic properties to generate a magnetic field when an electric current is applied, allowing the solenoid to perform its function effectively. The use of powder metal magnetic materials in solenoids enhances their performance, efficiency, and reliability, making them suitable for a wide range of applications, from automotive systems to industrial machinery. In the case of DC rotors and stators, powder metal magnetic materials play a crucial role in the construction of these components, which are essential for the operation of DC motors. The magnetic properties of these materials enable the efficient conversion of electrical energy into mechanical energy, driving the motor's rotation. The use of powder metal magnetic materials in DC rotors and stators contributes to improved motor performance, energy efficiency, and durability, making them ideal for applications in various industries, including automotive, aerospace, and industrial automation. Brushless DC motor rotors also benefit from the use of powder metal magnetic materials, which provide the necessary magnetic properties for the motor's operation. These materials enable the efficient generation of a magnetic field, which interacts with the motor's stator to produce rotational motion. The use of powder metal magnetic materials in brushless DC motor rotors enhances their performance, efficiency, and reliability, making them suitable for a wide range of applications, from electric vehicles to consumer electronics. The Global Powder Metal Magnetic Materials Market is witnessing significant growth due to the increasing demand for these materials in solenoids, DC rotors and stators, and brushless DC motor rotors. The automotive industry, in particular, is a major driver of this growth, as manufacturers seek to develop more efficient and environmentally friendly vehicles. The shift towards electric and hybrid vehicles is creating a demand for advanced magnetic materials that can enhance the performance of electric motors and other components. Similarly, the electronics industry is experiencing a surge in demand for compact and efficient magnetic components, driven by the proliferation of smart devices and the Internet of Things (IoT). The ability to produce high-performance magnetic materials with precise properties is a key factor in meeting the needs of these industries. Furthermore, ongoing research and development efforts are focused on improving the properties and applications of powder metal magnetic materials in solenoids, DC rotors and stators, and brushless DC motor rotors. Innovations in material composition, manufacturing processes, and design techniques are enabling the production of magnetic materials with enhanced performance and efficiency. These advancements are expected to further drive the growth of the Global Powder Metal Magnetic Materials Market, as industries continue to seek out new and improved solutions for their magnetic component needs. The market's expansion is also supported by the increasing adoption of renewable energy sources, which require efficient and reliable magnetic materials for the production of wind turbines, solar panels, and other energy generation systems. As the demand for clean and sustainable energy continues to rise, the need for advanced magnetic materials is expected to grow, further fueling the market's growth. Overall, the Global Powder Metal Magnetic Materials Market is poised for significant expansion, driven by the increasing demand for high-performance magnetic components across various industries.

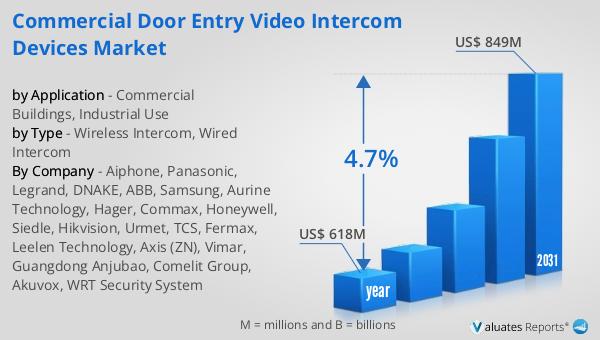

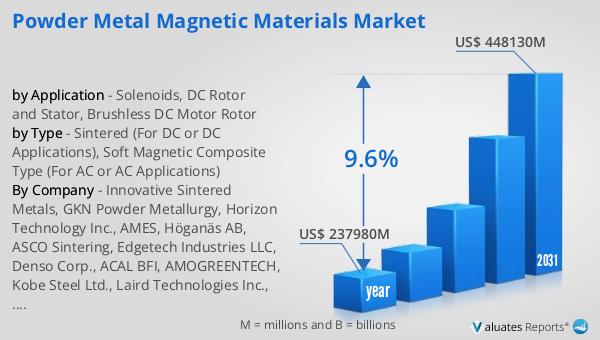

Global Powder Metal Magnetic Materials Market Outlook:

In 2024, the global market for Powder Metal Magnetic Materials was estimated to be worth approximately $237.98 billion. This market is anticipated to experience substantial growth over the coming years, with projections indicating it could reach an adjusted value of around $448.13 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 9.6% throughout the forecast period. The market's expansion is driven by several key factors, including the rising demand for energy-efficient and high-performance magnetic components across various industries. As technological advancements continue to shape the landscape, the need for smaller, lighter, and more efficient magnetic materials is becoming increasingly important. The automotive industry, in particular, is a significant contributor to this growth, as manufacturers strive to develop more efficient and environmentally friendly vehicles. The shift towards electric and hybrid vehicles is creating a demand for advanced magnetic materials that can enhance the performance of electric motors and other components. Similarly, the electronics industry is experiencing a surge in demand for compact and efficient magnetic components, driven by the proliferation of smart devices and the Internet of Things (IoT). The ability to produce high-performance magnetic materials with precise properties is a key factor in meeting the needs of these industries. Furthermore, ongoing research and development efforts are focused on improving the properties and applications of powder metal magnetic materials, ensuring they meet the evolving needs of various industries. These advancements are expected to further drive the growth of the Global Powder Metal Magnetic Materials Market, as industries continue to seek out new and improved solutions for their magnetic component needs. Overall, the market is poised for significant expansion, driven by the increasing demand for high-performance magnetic components across various industries.

| Report Metric | Details |

| Report Name | Powder Metal Magnetic Materials Market |

| Accounted market size in year | US$ 237980 million |

| Forecasted market size in 2031 | US$ 448130 million |

| CAGR | 9.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Innovative Sintered Metals, GKN Powder Metallurgy, Horizon Technology Inc., AMES, Höganäs AB, ASCO Sintering, Edgetech Industries LLC, Denso Corp., ACAL BFI, AMOGREENTECH, Kobe Steel Ltd., Laird Technologies Inc., Magnetics, Sanyo Special Steel Co.,Ltd., Sg Technologies Ltd., Sigma-Aldrich, Sintex A/S, Steward Advanced Materials Inc., Sumitomo Electric Industries, Taiyo Yuden Kk, TDK Corp., Toshiba Materials Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |