What is Global Polyvinyl Alcohol (PVA) Sponge Brush Market?

The Global Polyvinyl Alcohol (PVA) Sponge Brush Market is a specialized segment within the broader cleaning and maintenance industry, focusing on the production and distribution of sponge brushes made from polyvinyl alcohol. These brushes are known for their exceptional absorbency, durability, and softness, making them ideal for delicate cleaning tasks. PVA sponge brushes are widely used in various industries, including electronics, automotive, and healthcare, due to their ability to clean surfaces without scratching or leaving residues. The market is driven by the increasing demand for efficient and gentle cleaning solutions, particularly in high-tech industries where precision is crucial. As technology advances, the need for specialized cleaning tools like PVA sponge brushes continues to grow, supporting the market's expansion. The market is characterized by a few key players who dominate the industry, ensuring high-quality standards and innovation in product development. With the rise in global manufacturing and the emphasis on maintaining clean and contamination-free environments, the Global PVA Sponge Brush Market is poised for significant growth in the coming years. The market's focus on sustainability and eco-friendly products also aligns with the global trend towards environmentally conscious manufacturing practices.

Roll Shape, Sheet Shape in the Global Polyvinyl Alcohol (PVA) Sponge Brush Market:

In the Global Polyvinyl Alcohol (PVA) Sponge Brush Market, products are primarily categorized based on their shape, with roll shape and sheet shape being the most common. Roll-shaped PVA sponge brushes are designed for applications requiring continuous and uniform cleaning over large surfaces. These brushes are often used in automated cleaning systems where consistency and efficiency are paramount. The roll shape allows for easy integration into machinery, making them ideal for industrial settings where large-scale cleaning is necessary. The flexibility and adaptability of roll-shaped brushes make them a preferred choice in sectors like semiconductor manufacturing, where precision cleaning is essential to prevent contamination and ensure product quality. On the other hand, sheet-shaped PVA sponge brushes are typically used for more manual cleaning tasks. These brushes are versatile and can be cut to size, making them suitable for a variety of applications. Sheet-shaped brushes are often used in environments where detailed and controlled cleaning is required, such as in laboratories or cleanrooms. The ability to customize the size and shape of these brushes allows for targeted cleaning, ensuring that even the most intricate components are free from dust and debris. Both roll and sheet-shaped PVA sponge brushes are valued for their high absorbency and gentle cleaning properties. The unique structure of PVA material allows these brushes to hold a significant amount of liquid, making them effective at removing contaminants without the need for harsh chemicals. This property is particularly important in industries where chemical residues could damage sensitive components or interfere with manufacturing processes. The choice between roll and sheet shapes often depends on the specific requirements of the cleaning task at hand. In industries where automated systems are prevalent, roll-shaped brushes offer the advantage of seamless integration and continuous operation. Conversely, in settings where precision and adaptability are crucial, sheet-shaped brushes provide the flexibility needed to achieve optimal cleaning results. As the demand for high-quality cleaning solutions continues to rise, manufacturers in the Global PVA Sponge Brush Market are focusing on innovation and product development to meet the diverse needs of their customers. This includes the development of new materials and designs that enhance the performance and durability of PVA sponge brushes. By understanding the unique characteristics and applications of roll and sheet-shaped brushes, businesses can make informed decisions about the best cleaning solutions for their specific needs. The ongoing advancements in PVA sponge brush technology are expected to drive further growth in the market, as industries continue to seek out efficient and reliable cleaning tools to support their operations.

Semiconductor, Data Storage (HDD), Others in the Global Polyvinyl Alcohol (PVA) Sponge Brush Market:

The Global Polyvinyl Alcohol (PVA) Sponge Brush Market finds significant usage in various high-tech industries, including semiconductors, data storage (HDD), and others. In the semiconductor industry, PVA sponge brushes are essential for maintaining the cleanliness and integrity of wafers during the manufacturing process. These brushes are used to remove particles and contaminants from the wafer surface, ensuring that the delicate electronic components are free from defects. The high absorbency and gentle cleaning action of PVA sponge brushes make them ideal for this application, as they can effectively clean without scratching or damaging the sensitive surfaces. In the data storage industry, particularly in the production of hard disk drives (HDD), PVA sponge brushes play a crucial role in ensuring the cleanliness of the disk platters. Any contamination on the disk surface can lead to data loss or drive failure, making precise cleaning essential. PVA sponge brushes are used to remove dust and debris from the platters, ensuring that the drives operate smoothly and reliably. The ability of these brushes to hold and release cleaning solutions evenly makes them particularly effective in this application, as they can thoroughly clean the disk surface without leaving residues. Beyond semiconductors and data storage, PVA sponge brushes are also used in a variety of other industries where precision cleaning is required. In the automotive industry, for example, these brushes are used to clean delicate components such as sensors and electronic control units. The healthcare industry also relies on PVA sponge brushes for cleaning medical devices and equipment, where maintaining a sterile environment is critical. The versatility of PVA sponge brushes makes them suitable for a wide range of applications, from cleaning optical lenses to maintaining cleanroom environments. As industries continue to advance and the demand for high-quality, contamination-free products grows, the usage of PVA sponge brushes is expected to increase. Manufacturers are continually developing new formulations and designs to enhance the performance of these brushes, ensuring that they meet the evolving needs of their customers. The focus on sustainability and eco-friendly products is also driving innovation in the PVA sponge brush market, as businesses seek to reduce their environmental impact while maintaining high standards of cleanliness. Overall, the Global PVA Sponge Brush Market plays a vital role in supporting the operations of various high-tech industries, providing the tools needed to achieve precise and effective cleaning.

Global Polyvinyl Alcohol (PVA) Sponge Brush Market Outlook:

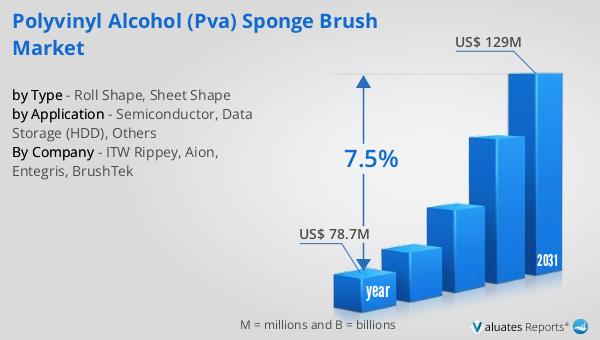

The market outlook for the Global Polyvinyl Alcohol (PVA) Sponge Brush Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $78.7 million, and it is anticipated to expand to a revised size of around $129 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.5% over the forecast period. A significant factor contributing to this growth is the dominance of the top three manufacturers, who collectively hold a market share exceeding 90%. This concentration of market power among a few key players ensures a high level of quality and innovation in the products offered. Within the market, the roll shape segment emerges as the largest, accounting for over 80% of the product share. This preference for roll-shaped PVA sponge brushes is likely due to their versatility and efficiency in various industrial applications, particularly in automated cleaning systems. The ability of roll-shaped brushes to provide consistent and uniform cleaning over large surfaces makes them a preferred choice in sectors such as semiconductor manufacturing and data storage. As industries continue to prioritize cleanliness and contamination control, the demand for high-quality PVA sponge brushes is expected to rise, further driving market growth. The focus on sustainability and eco-friendly products also aligns with global trends, supporting the market's expansion as businesses seek to adopt environmentally conscious practices. Overall, the Global PVA Sponge Brush Market is poised for significant growth, driven by technological advancements, increasing demand for precision cleaning solutions, and the continued dominance of key market players.

| Report Metric | Details |

| Report Name | Polyvinyl Alcohol (PVA) Sponge Brush Market |

| Accounted market size in year | US$ 78.7 million |

| Forecasted market size in 2031 | US$ 129 million |

| CAGR | 7.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ITW Rippey, Aion, Entegris, BrushTek |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |